Titanium-dioxide-doped composite magnetic nano-grade adsorbent, preparation method thereof, and application thereof

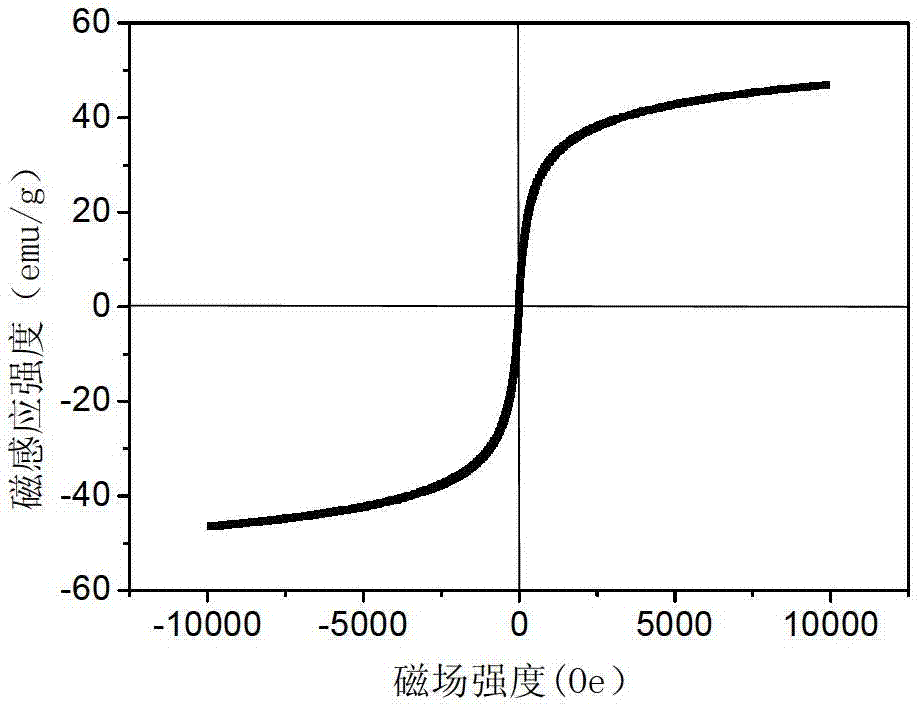

A technology of titanium dioxide and adsorbent, which is applied in the field of water treatment and regeneration, can solve the difficult and difficult problems of catalyst recovery and reuse, and achieve the effects of easy separation, recovery and regeneration, consumption saving, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

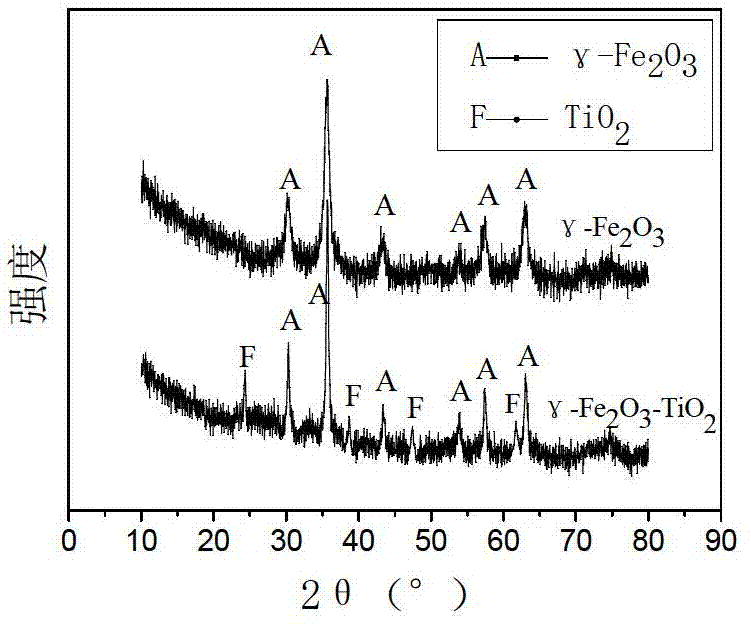

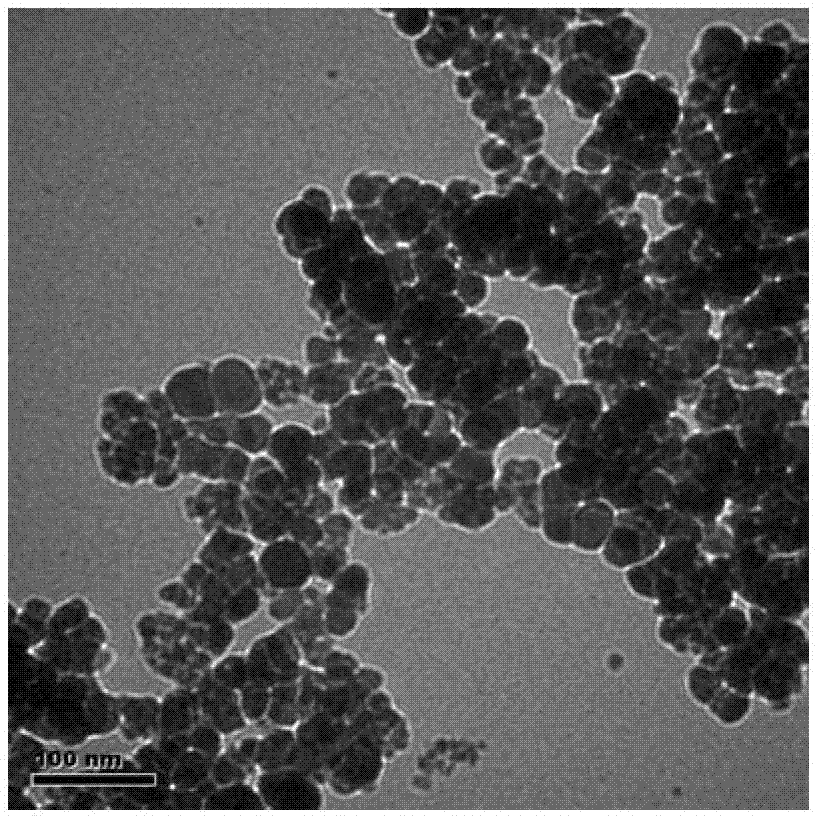

[0038] Accurately weigh 5.41g of FeCl 3 ·6H 2 O, 1.99 g FeCl 2 4H 2 O, 0.19 g TiCl 4 , dissolve in deionized water, add ammonia water while stirring, so that the pH of the solution is 8, black particles appear in the solution, continue to add deionized water, and set the volume to 200ml to obtain a mixed solution, and put the mixed solution in a water bath at 45°C Stir for 1 hour, put the mixture in an incubator at 70°C to age for 1 hour, then use a magnet to separate the black particles from the mixture, rinse with deionized water until the rinse solution does not detect Cl - ions, and filter with filter paper, dry the obtained black particles at 30°C for 24 hours, take them out and grind them into powder, and roast the black powder at 250°C in air for 2 hours to obtain the product.

Embodiment 2

[0040] Accurately weigh 5.41g of FeCl 3 ·6H 2 O, 1.99 g FeCl 2 4H 2 O, 0.95g TiCl 4 , was dissolved in deionized water, and ammonia water was added while stirring, so that the pH of the mixed solution was 9, black particles were produced in the mixed solution, and deionized water was continued to be added, and the volume was constant to 200ml to obtain a mixed solution. Stir the mixed solution in a 55°C water bath for 0.5h, put the mixed solution in a 50°C incubator to age for 0.5h, then use a magnet to separate the black particles from the solution, and rinse with deionized water until the rinse solution cannot be detected Cl - Ions, and filtered with filter paper, the obtained black particles were dried at 40°C for 24 hours, taken out and ground into powder, and the black powder was roasted in air at 250°C for 2 hours to obtain the product.

Embodiment 3

[0042] Accurately weigh 8.08g of Fe(NO 3 ) 3 9H 2 O, 11.52g of Fe(NO 3 ) 2 ·6H 2 O, 1.44g Ti (SO 4 ) 2 , dissolved in deionized water, adding sodium hydroxide while stirring, so that the pH of the mixed solution is 6, black particles are produced in the mixed solution, continue to add deionized water, and set the volume to 300ml to obtain a mixed solution, and put the mixed solution in Stir in a water bath at 25°C for 3 hours, then use a magnet to separate the black particles from the mixture, rinse with deionized water until the rinse solution does not detect Cl - ions, and filter with filter paper, dry the obtained black particles at 20°C for 48h, take them out and grind them into powder, roast the black powder at 200°C in pure nitrogen for 2h, and then roast at 200°C for 1h under air condition to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com