Method for preparing Mn-doped bismuth sodium titanate-barium titanate film

A technology of bismuth sodium titanate and barium titanate, which is applied in the field of preparation of bismuth sodium titanate-barium titanate thin film, can solve environmental hazards and other problems, and achieve the effects of convenient operation, good repeatability and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of the target: with high-purity Bi 2 o 3 , Na 2 CO 3 , BaCO 3 , TiO 2 As raw material, according to the chemical formula 0.935Bi 0.5 Na 0.5 TiO 3 -0.065BaTiO 3 Weigh the stoichiometric ratio of -0.005Mn, wet grind the raw materials with zirconium balls in absolute ethanol for 6 hours, then dry, press into tablets, and calcined at 850°C for 2 hours to obtain perovskite structure powder ; The obtained perovskite structure powder is ball-milled twice, dried, pressed into tablets, and sintered at 1200° C. for 2 hours to obtain the target material.

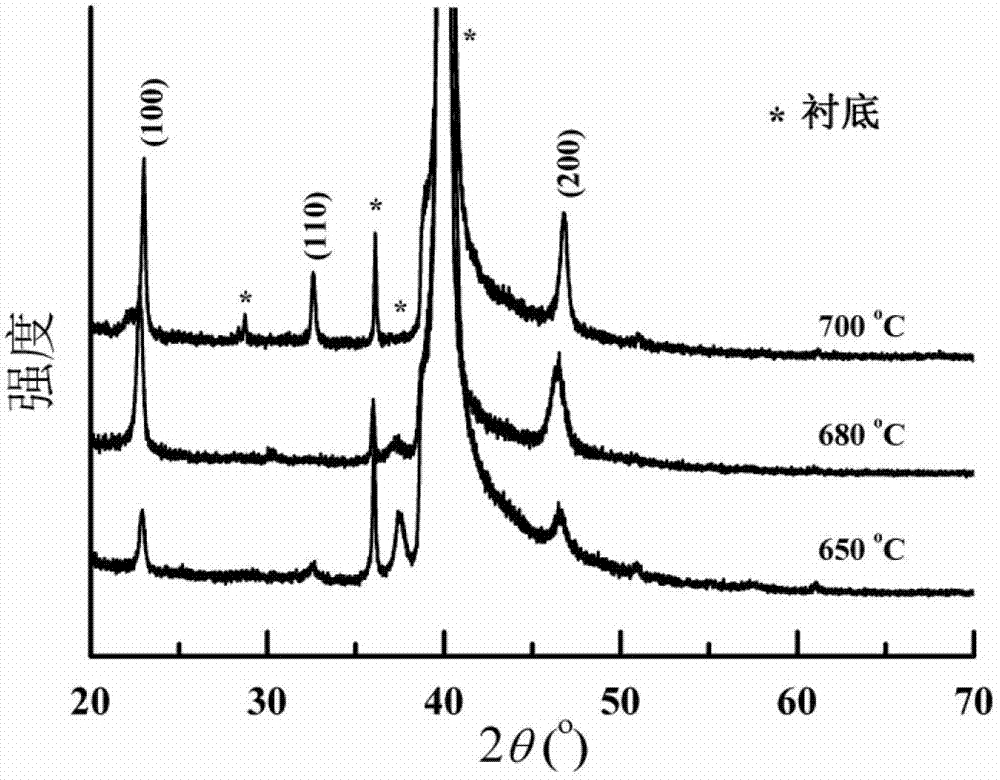

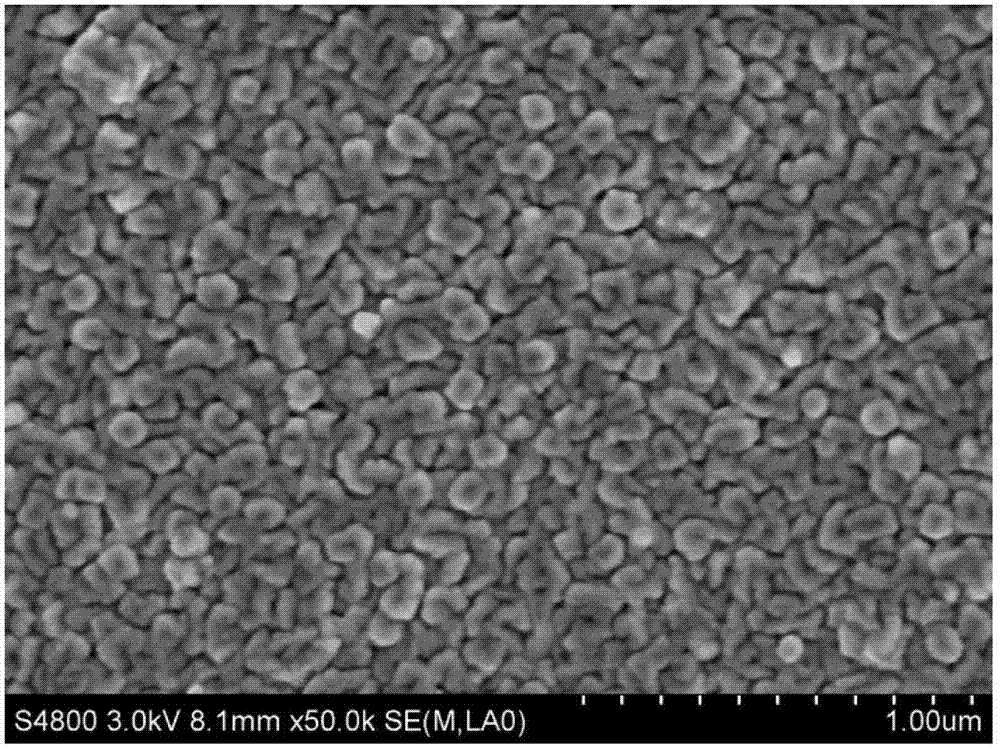

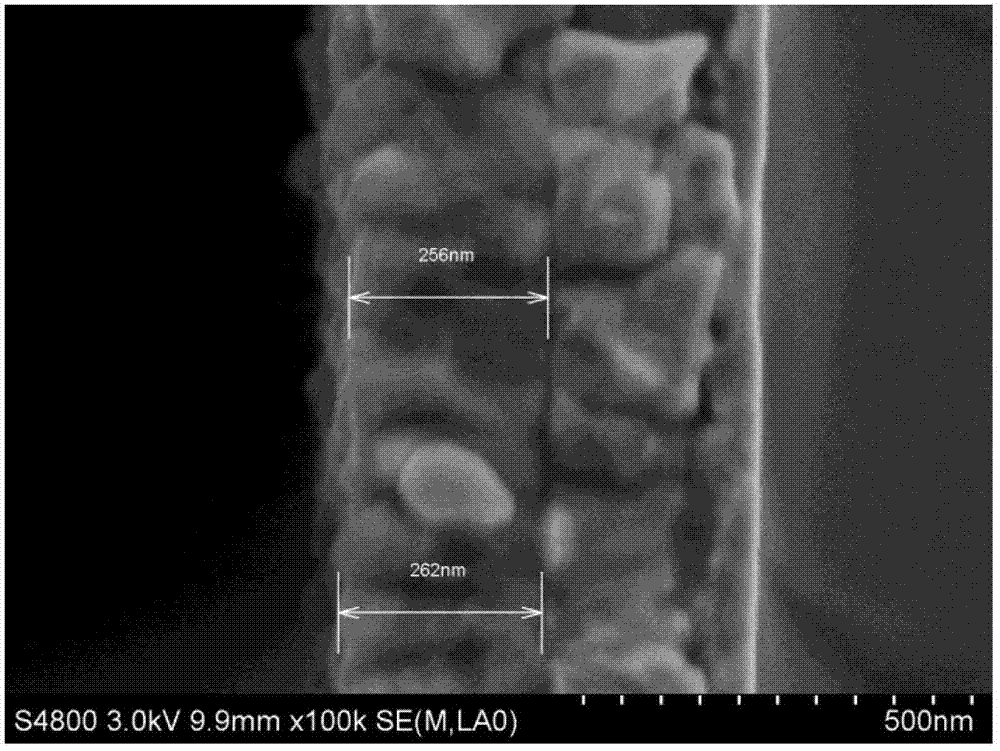

[0029] (2) Prepare thin films by pulsed laser deposition system, adjust target-base distance to 5.5cm, sputtering temperature at 650°C, 680°C and 700°C, power at 300mJ, frequency at 8Hz, feed oxygen, adjust air pressure to 30Pa, sputter for 40min, then Anneal at the deposition temperature for 30min, keep the oxygen pressure and naturally cool to room temperature to prepare the Mn-doped sodium bismuth tit...

Embodiment 2

[0032] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that according to the chemical formula 0.97Bi 0.5 Na 0.5 TiO 3 -0.03BaTiO 3 -0.005Mn for batching.

Embodiment 3

[0034] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that according to the chemical formula 0.96Bi 0.5 Na 0.5 TiO 3 -0.04BaTiO 3 -0.005Mn for batching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com