Preparation method of zinc 5, 5'-azotetrazole

A technology of zinc azotetrazolium and sodium azotetrazolium, which is applied in the field of preparation of primers, can solve the problems of excessive sensitivity, poor explosive performance, easy to ignite and the like, and achieves less environmental and human harm, and a simple destruction method. , the effect of a simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

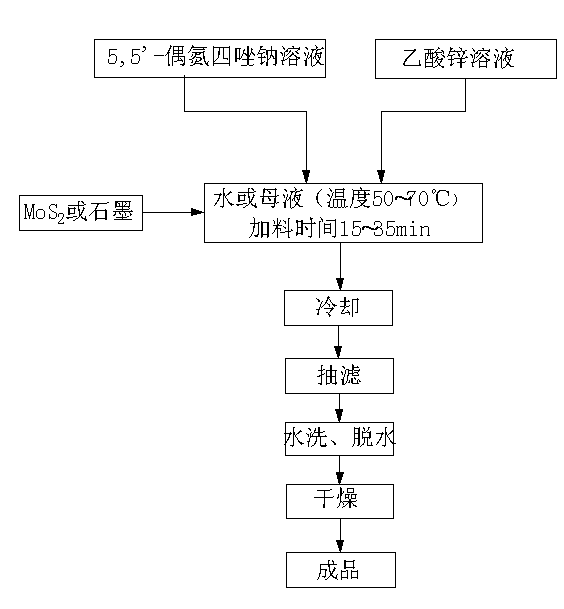

[0014] In the preparation method of 5,5'-azotetrazole zinc of the present invention, the reaction temperature of the 5,5'-azotetrazole sodium solution, the soluble zinc salt solution and the bottom liquid is 50-70°C.

[0015] The preparation method of 5,5'-azotetrazole zinc of the present invention, the holding time: 6min-10min, cooling temperature ≤ 45°C, washing 2-3 times, dehydrating with ethanol 1-2 times, drying temperature 55-60°C , drying time ≥ 2h.

[0016] Elemental analysis of ZnATZ / %: calculated value, C9.06, N52.26, H1.51; measured value, C9.13, N53.26, H1.43. Due to the existence of metal Zn, there is a certain deviation between the measured data and the calculated value. The Zn content in the product was determined by volumetric titration method to be 24.42%, the theoretical value was 24.53%, and the relative deviation was 0.45%. Accordingly, it can be inferred that the product contains a Zn atom.

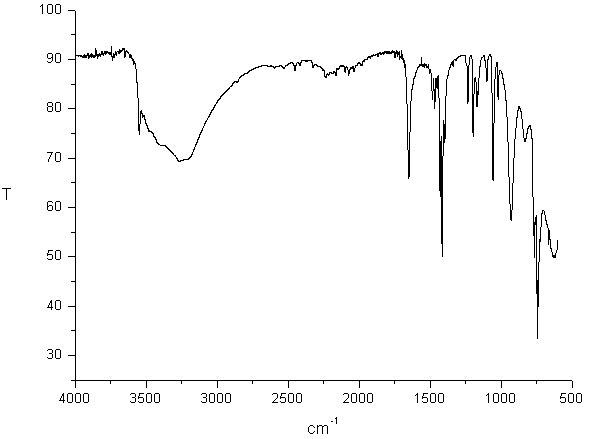

[0017] combined with figure 1 ZnATZ peak (cm -1 ) for 3547...

Embodiment 1

[0022] Example 1: Raw material specifications and requirements: anhydrous sodium sulfite (NaSO3) AR, sodium hydroxide (NaOH) AR, potassium permanganate (KMnO4) chemically pure, ethanol (CH3CH2OH) C·P, main equipment: electric stirrer ; Voltage regulating transformer, super constant temperature water bath; tall beaker (combiner) 400mL, Buchner funnel φ65mm; filter bottle 1000mL, water circulation vacuum pump.

[0023] Add 17g of anhydrous 5-aminotetrazole into 100mL of 2mol / L NaOH solution, stir to dissolve, place in a water bath at 60-70°C, add 20g of potassium permanganate in batches under vigorous stirring, and excess potassium permanganate Titrate with a sufficient amount of NaSO3 solution or ethanol solution, and the end point is that the solution changes from green to yellow. After boiling for 30 minutes, filter while hot, filter out the brown suspended matter MnO2, wash twice with hot water and pour out the filtrate, cool to room temperature and filter with suction to ob...

Embodiment 2

[0025] Example 2: Combining figure 1 , raw material specifications and requirements: 5-aminotetrazole, zinc acetate (ZnAc2 2H2O) AR, MoS2, ethanol (CH3CH2OH) C P, main equipment: electric stirrer; voltage regulating transformer, super constant temperature water bath,; high type Beaker (combiner) 400mL, metering pump, Buchner funnel φ65mm; filter bottle 1000mL, water bath oven, water circulation vacuum pump.

[0026]According to the raw material feeding ratio (mass ratio): ZnAc2 2H2O: C2N10Zn 5H2O=1.10:1, measure 50mL of pure water and add it to the compounder as the bottom liquid, add 0.16g MoS2, and place it in a constant temperature water bath at 65°C. Weigh 3.00g (0.06mol) SZT·5H2O and add 50ml of pure water, heat and dissolve in the same water bath, dissolve 3.29g (0.015mol) Zn(CH3COO)2·2H2O in 30ml of pure water, install the reaction device, and calibrate the measurement Pump. Start the stirrer, adjust the voltage to an appropriate stirring state, and stir at a constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com