Method for preparing mono-disperse polymer functional microspheres with photochemical method

A monodisperse, polymer technology, applied in the field of preparing monodisperse polymer functional microspheres, can solve the problems of uneven particle size, size, dispersibility, purity, resilience and thermal expansion that are difficult to meet requirements, and achieve polymerization reaction. The effect of rapidity, high production efficiency and low energy consumption

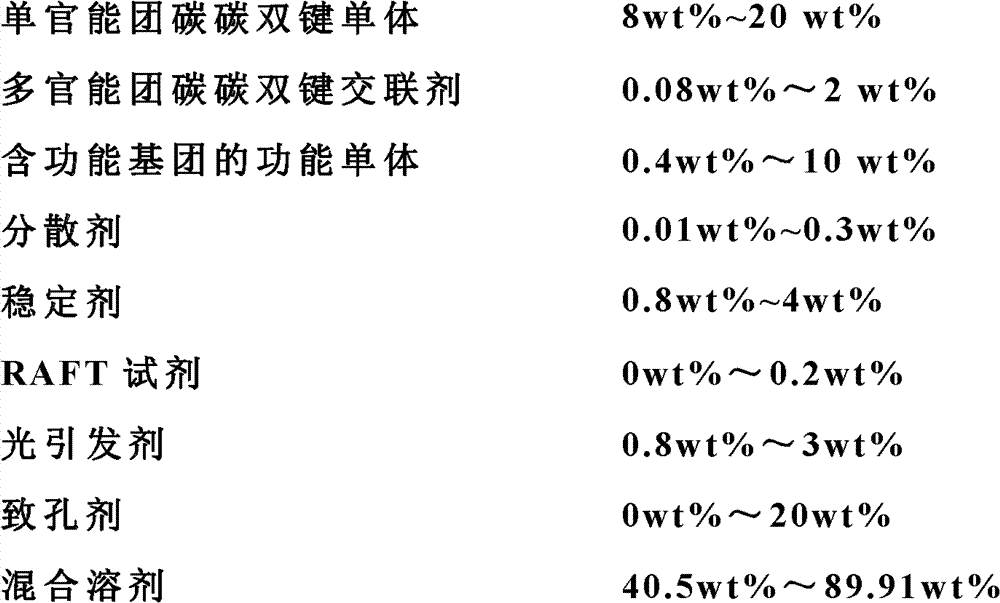

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

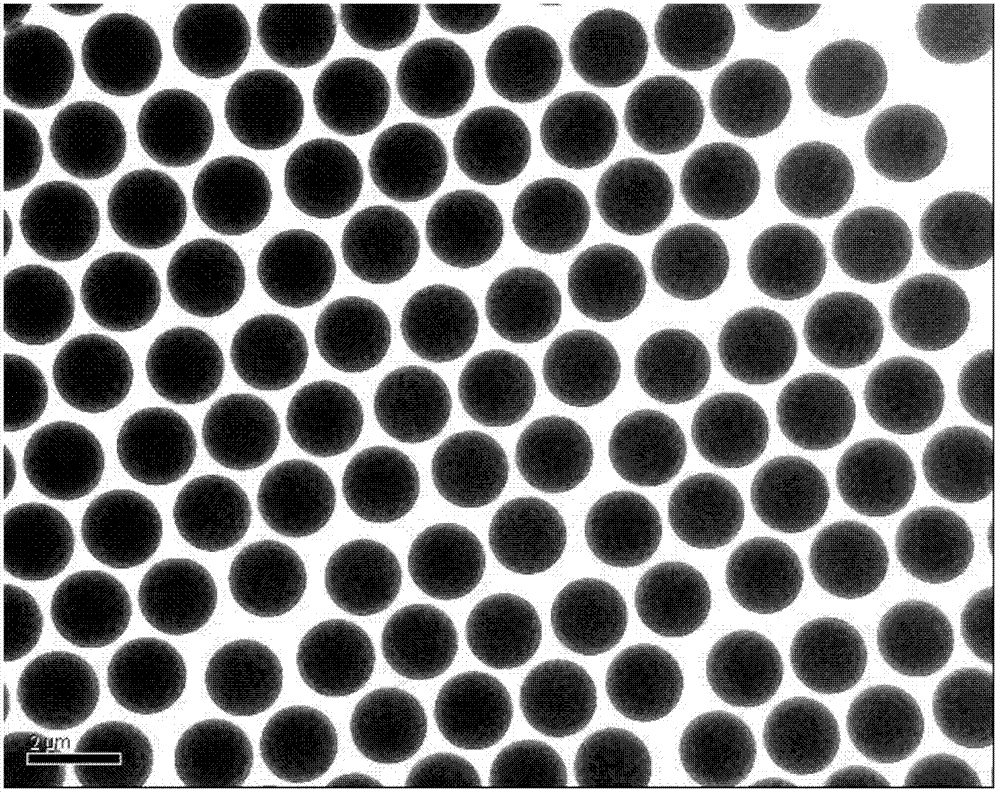

[0054] The synthesis of embodiment 1 solid cross-linked polystyrene microspheres

[0055] Take by weighing 15g of styrene (St) treated with 5% NaOH solution, 7.5g of divinylbenzene (DVB) treated, 0.15g of sodium lauryl sulfate (SLS), 0.1g of Tween 80, polyethylene Pyrrolidone PVP-K90 3.0g, RAFT reagent N-carbazole dithioisobutyronitrile (CYCBD) 0.15g, photoinitiator 2, 4, 6 (trimethylbenzoyl) diphenylphosphine oxide (TPO) Add 0.15g, 60g ethanol, 60g ethylene glycol monoether, and 200g water into a 500ml single-necked flask, and use an ultrasonic homogenizer to sonicate for more than 30 minutes, and cool while sonicating to make a uniform and stable dispersion.

[0056] The dispersion liquid was transferred into a 500ml four-necked reaction bottle equipped with a condenser and a thermometer, stirred and vacuumed, filled with nitrogen to a constant pressure, and adjusted the nitrogen flow rate until small bubbles escaped intermittently. At room temperature, irradiate with a hom...

Embodiment 2

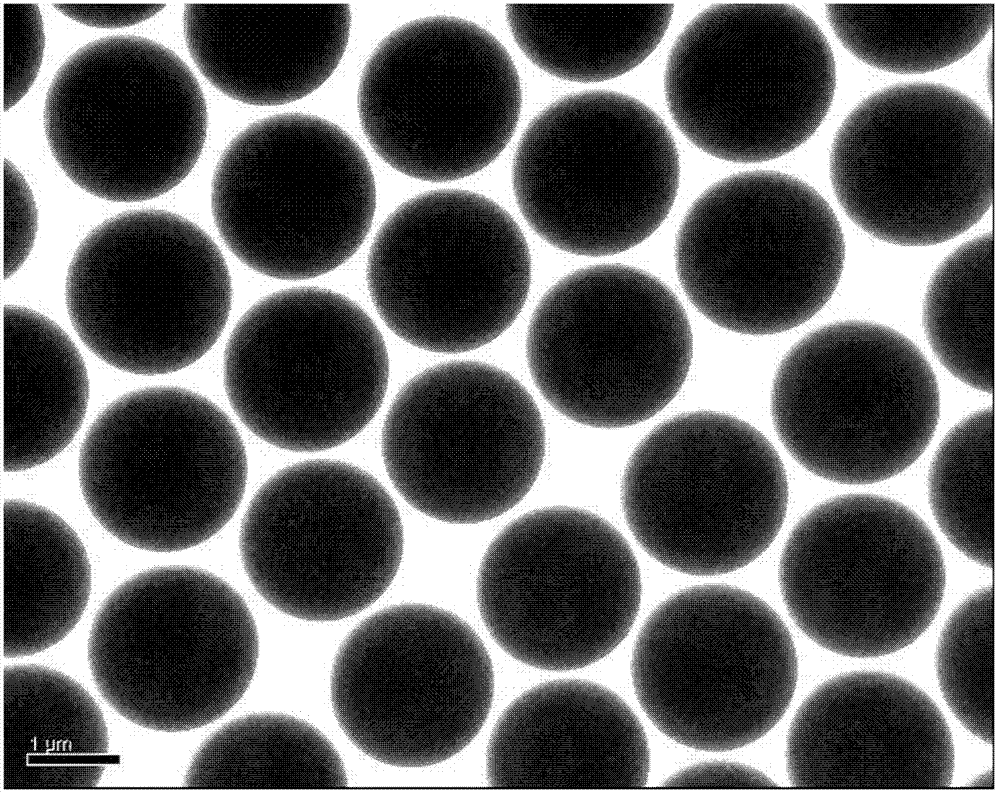

[0057] The synthesis of embodiment 2 porous cross-linked polystyrene microspheres

[0058] In the reaction raw material formulation in Example 1, 10 g of cyclohexane was added to obtain porous cross-linked polystyrene microspheres with a size of 1.0 μm. The operating steps are the same as in Example 1.

Embodiment 3

[0059] Example 3 Synthesis of amino-containing cross-linked polystyrene microspheres

[0060] In the reaction raw material formula in embodiment 1, add 3.0g epoxy vinyl ethers of methacrylic acid, can obtain the solid cross-linked polystyrene microsphere that size is 1.6 μ m and surface contains epoxy group, microsphere uses ethylenediamine After treatment, the amino group-containing cross-linked polystyrene microspheres can be obtained, which can be used to prepare conductive microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com