Preparation method and application of deep-sea extracellular polymeric substances

A deep-sea bacteria and extracellular polysaccharide technology, applied in microorganism-based methods, biochemical equipment and methods, preparations for skin care, etc., can solve the problems of low degree of development and utilization, achieve good free radical scavenging ability, good moisture absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

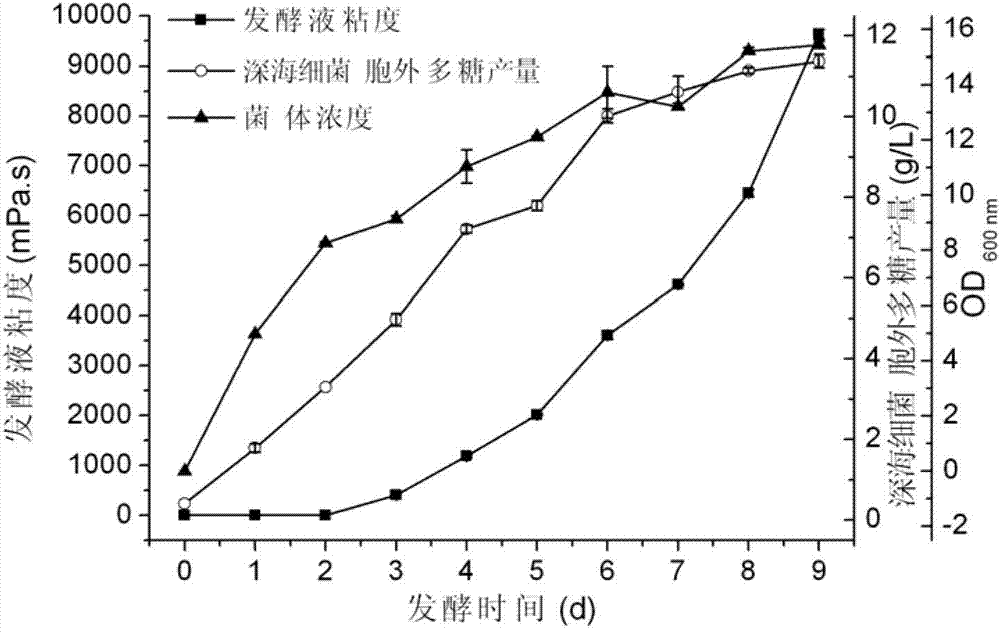

[0039] A preparation method of deep-sea bacterial exopolysaccharide, the steps are as follows:

[0040](1) Streak inoculate the purchased deep-sea bacteria (Zunongwangia profunda) SM-A87 strain on solid medium, activate and culture at 20°C for 3 days, then inoculate in 100mL liquid seed medium, and inoculate at 20°C, 200rpm Shake culture under conditions for 2 days, then inoculate 5L of fermentation medium at an inoculum size of 5% (v / v), culture for 24 hours at 20°C and dissolved oxygen saturation of 80-100%, and then adjust the fermentation temperature At 10°C, continue to cultivate for 9 days, and add 500 mL of lactose solution with a concentration of 200 g / L prepared by lactose and artificial seawater on the third and fifth days of continued cultivation to prepare a fermentation broth;

[0041] The above-mentioned solid medium components are as follows, all in parts by weight:

[0042] 1 part of peptone, 0.5 parts of yeast powder, 1.5 parts of agar, 100 parts of artificia...

Embodiment 2

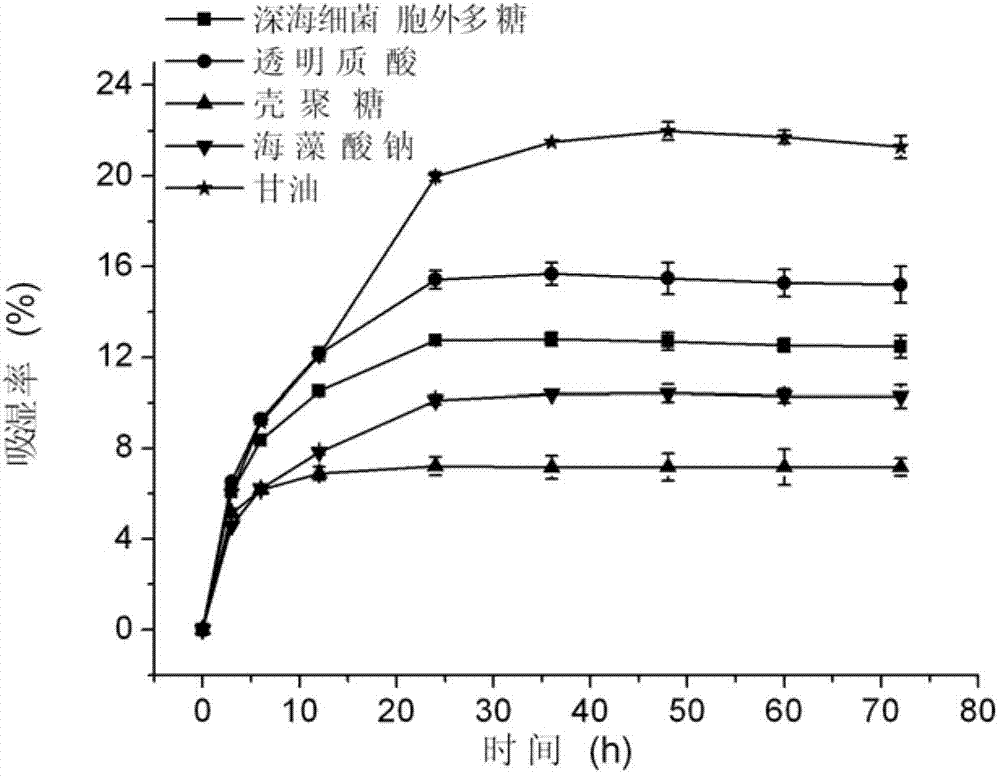

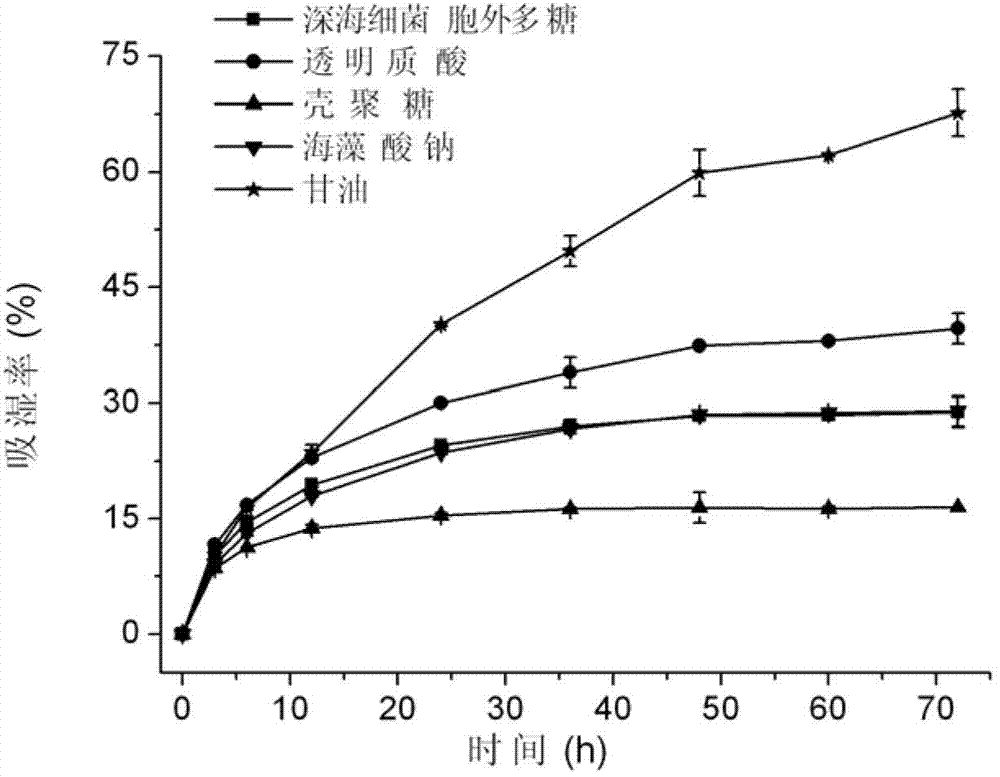

[0049] Embodiment 2: Determination of moisture absorption and moisture retention performance of deep-sea bacterial exopolysaccharide

[0050] The specific method for the determination of the hygroscopicity of deep-sea bacterial exopolysaccharides is as follows:

[0051] The saturated ammonium sulfate solution and the saturated potassium carbonate solution were placed in two desiccators (300mm in diameter) respectively, and stored in a constant temperature box at 25°C to make environments with relative humidity of 81% and 43%, respectively.

[0052] Grind deep-sea bacterial exopolysaccharide, hyaluronic acid, chitosan oligosaccharide and sodium alginate to 80 mesh, put them in a vacuum desiccator together with glycerin, and use P 2 o 5 As a desiccant, dry at 40°C to constant weight.

[0053] Accurately weigh 0.5000g (accurate to 0.0001g) of deep-sea bacterial exopolysaccharide, hyaluronic acid, chitosan oligosaccharide and sodium alginate respectively, put them into 25×25mm w...

Embodiment 3

[0067] Determination of antioxidant properties of deep-sea bacterial exopolysaccharides, the specific method is as follows:

[0068] 1. Scavenging effect on organic free radicals (DPPH·)

[0069] The deep-sea bacterial exopolysaccharide deionized water was made into 0.1, 0.25, 0.5, 1.0, 2.0, 3.0, 5.0, 7.5 and 10.0 mg / mL solutions as sample groups. Vitamin C and hyaluronic acid were made into solutions of the same concentration with deionized water as a control group.

[0070] Dissolve DPPH with a small amount of absolute ethanol, and then use 50% ethanol to make a solution with a concentration of 100 μM.

[0071] Add 2mL of DPPH solution into a 10mL centrifuge tube, then add 1mL of sample solution, mix well, react at room temperature in the dark for 40min, and measure the absorbance Ai at 525nm.

[0072] Replace the sample with 1mL deionized water as the blank control tube, replace the DPPH solution with 2mL of 50% ethanol and add 1mL of polysaccharides with different concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com