Low-temperature corrosion inhibitor

A corrosion inhibitor and low-temperature technology, applied in the field of low-temperature corrosion inhibitors, can solve problems such as difficult prevention, single protective measures, and complex corrosion mechanism, and achieve the effect of strengthening corrosion inhibition, inhibiting corrosion, and good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

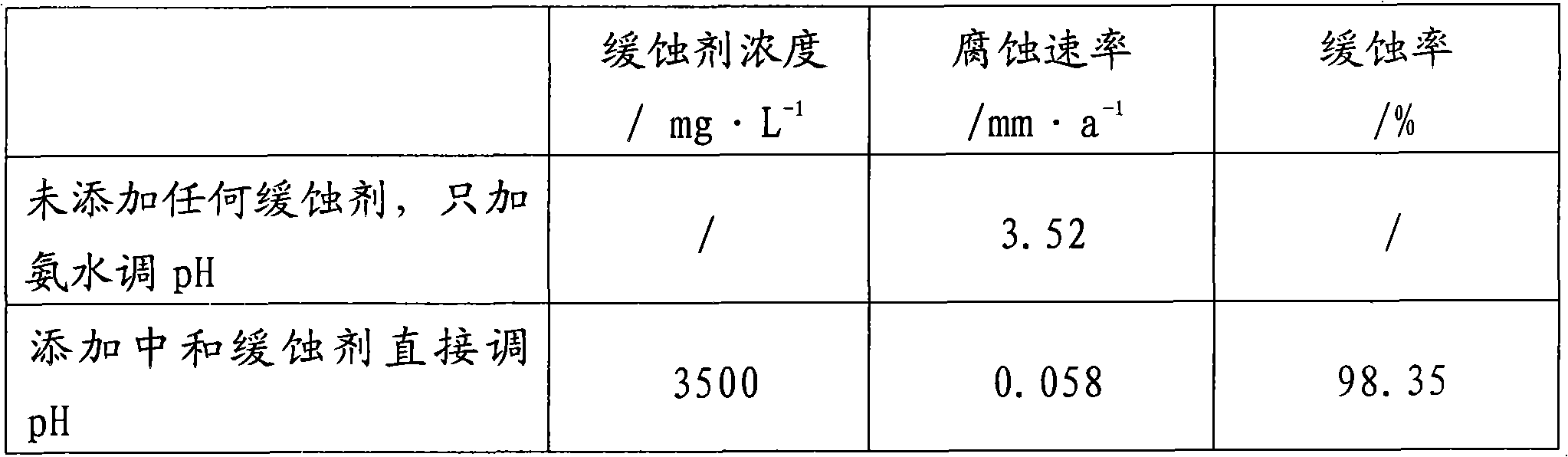

Examples

Embodiment 1

[0015] This embodiment discloses a low-temperature corrosion inhibitor, its composition and mass percentage are:

[0016] Compound solvent 30%, water-soluble imidazoline compound 40%, acetylenic alcohol compound 7%, nitrogen-containing adsorption corrosion inhibitor 15%, passivation corrosion inhibitor 5%, mercapto-substituted carboxylic acid 3%;

[0017] The compound solvent is formed by mixing water and methanol, wherein the mass content of the water is 20%, and the mass content of the methanol is 10%;

[0018] The water-soluble imidazoline compound is composed of naphthenic acid imidazoline;

[0019] The acetylenic alcohol compound consists of propynyl alcohol;

[0020] The nitrogen-containing adsorption type corrosion inhibitor is composed of benzotriazole;

[0021] The passivation type corrosion inhibitor is composed of ammonium nitrite in nitrite;

[0022] The mercapto-substituted carboxylic acid consists of dimercaptosuccinic acid.

[0023] The preparation method of...

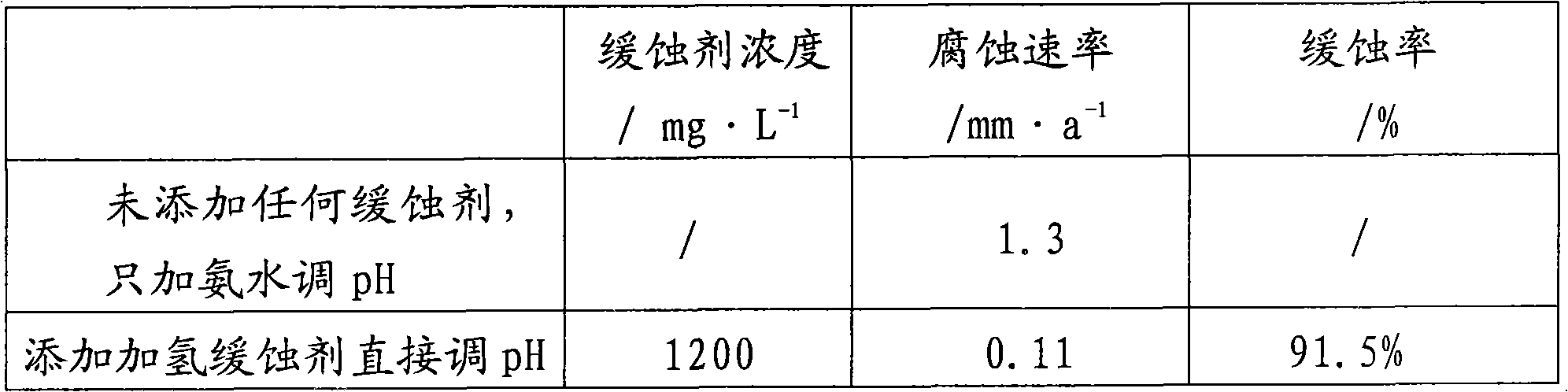

Embodiment 2

[0029] This embodiment discloses a low-temperature corrosion inhibitor, its composition and mass percentage are:

[0030] Compound solvent 23%, water-soluble imidazoline compound 42%, acetylene alcohol compound 8%, nitrogen-containing adsorption corrosion inhibitor 20%, passivation corrosion inhibitor 3%, mercapto-substituted carboxylic acid 4%;

[0031] The compounding solvent is composed of water,

[0032] The water-soluble imidazoline compound is composed of imidazoline oleate;

[0033] The acetylenic alcohol compound is composed of butynediol diethoxy ether;

[0034] The nitrogen-containing adsorption type corrosion inhibitor is composed of benzothiazole;

[0035] The passivation type corrosion inhibitor is made up of ammonium nitrate in nitrate;

[0036] The mercapto-substituted carboxylic acid consists of thioglycolic acid.

[0037] The preparation method of the low temperature corrosion inhibitor described in the present embodiment is as follows:

[0038] First, pu...

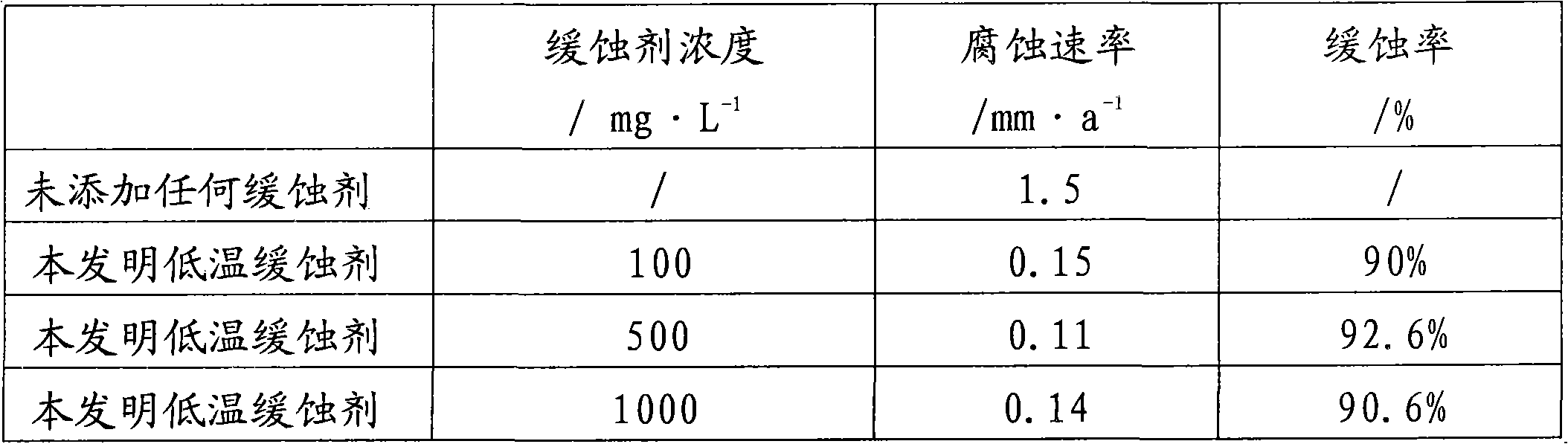

Embodiment 3

[0041] This embodiment discloses a low-temperature corrosion inhibitor, its composition and mass percentage are:

[0042] Compound solvent 21%, water-soluble imidazoline compound 45%, acetylenic alcohol compound 6%, nitrogen-containing adsorption corrosion inhibitor 23%, passivation corrosion inhibitor 3%, mercapto-substituted carboxylic acid 2%;

[0043] The compound solvent consists of water,

[0044] The water-soluble imidazoline compound is composed of naphthenic acid imidazoline;

[0045] The alkynyl alcohol compound consists of hydroxypropargyl ether;

[0046] The nitrogen-containing adsorption type corrosion inhibitor is composed of urotropine;

[0047] The passivation type corrosion inhibitor is made up of ammonium borate;

[0048] The mercapto-substituted carboxylic acid consists of mercaptopropionic acid.

[0049] The preparation method of the low temperature corrosion inhibitor described in the present embodiment is as follows:

[0050] First put water, imidazo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion inhibition rate | aaaaa | aaaaa |

| Corrosion inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com