Functional material with CuO and In2O3 micro-nano heterogeneous periodic structure and preparation method thereof

A technology of periodic structure and functional materials, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of unsatisfactory light utilization rate gas sensitivity, low light utilization rate, small specific surface area, etc. problem, to achieve the effect of high sensitivity, controllable growth area, stable and ordered structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Use deionized water, adjust the pH value to 4.0 with nitric acid, take 30mL, add 0.2174g copper nitrate and 0.1718g indium nitrate, and sonicate for 10min to make a uniform electrolyte.

[0034] 2) In a temperature-controllable growth chamber, use the surface oxidized silicon wafer as the substrate, place two copper foil electrodes with a thickness of about 30 μm in parallel on the substrate, and the distance between the two electrodes is 5-10mm, and drop electrolyte between the electrodes, cover On the coverslip, blot excess electrolyte solution from the edge of the substrate with filter paper.

[0035] 3) The electrolyte was refrigerated and frozen by using a low-temperature constant temperature circulator and a semiconductor refrigeration element, so that the ice layer evenly covered the substrate, and the growth temperature was lowered to minus 3.5 degrees for 20 minutes.

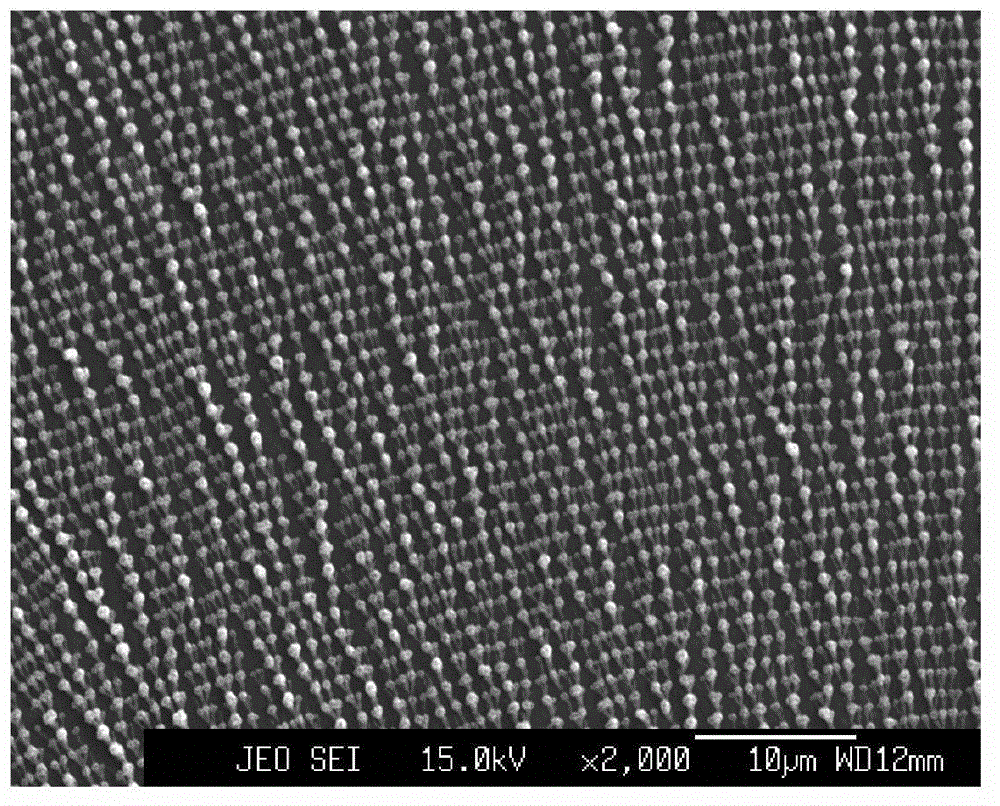

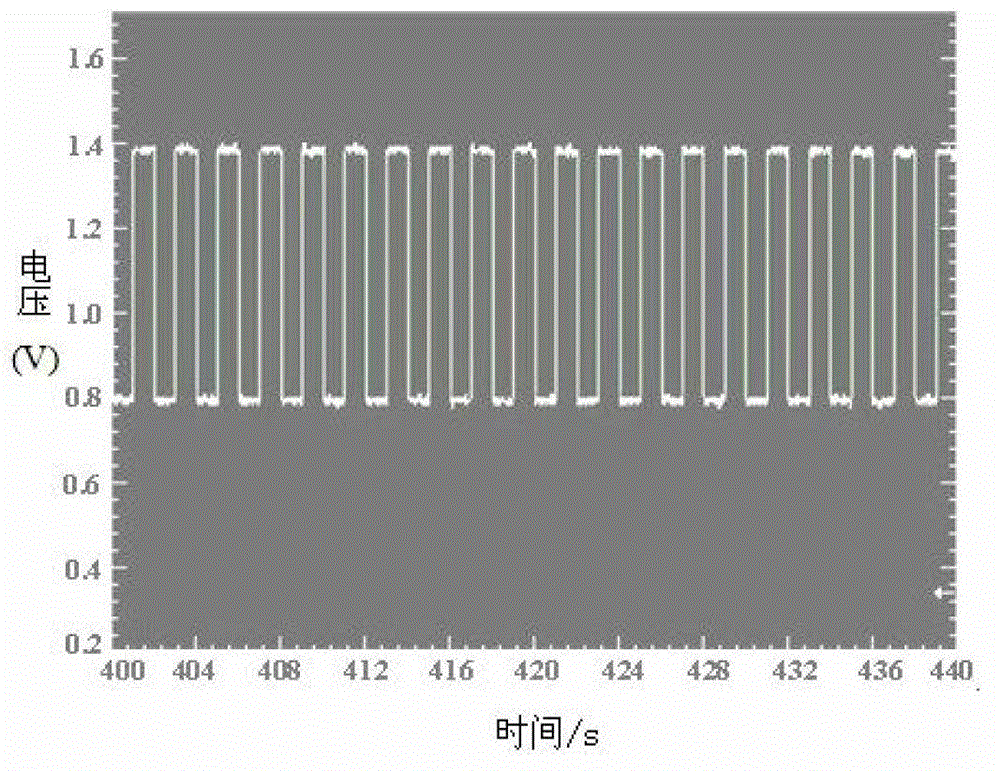

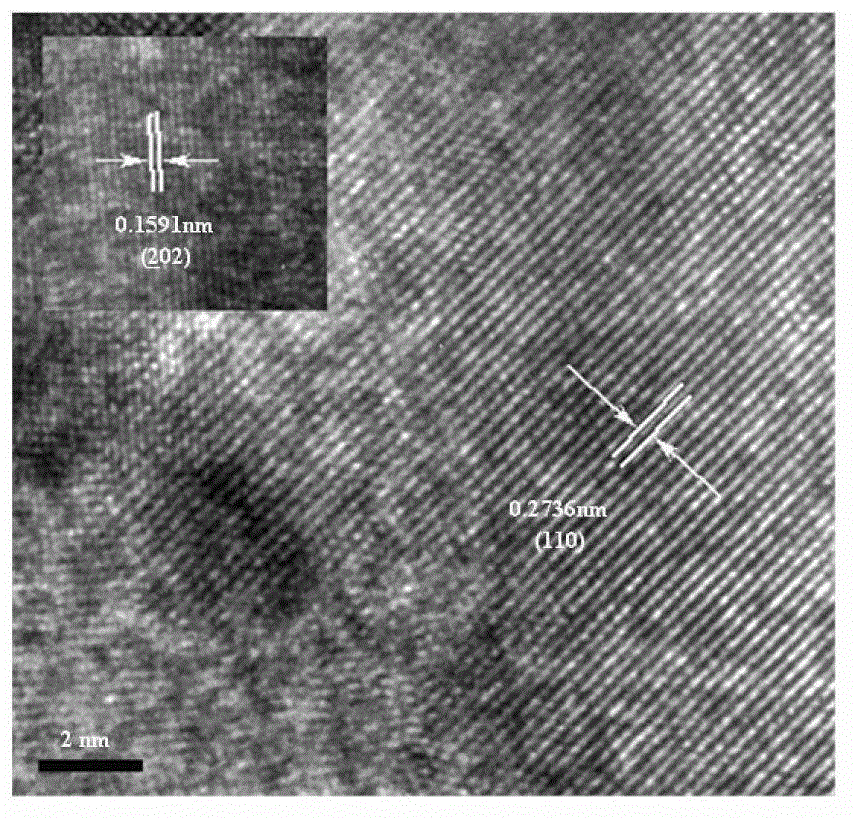

[0036] 4) Apply a 0.5Hz square wave voltage (0.8V-1.4V) across the electrodes to make Cu ...

Embodiment 2

[0041] 1) Use deionized water, adjust the pH value to 3.0 with nitric acid, take 30mL, add 0.2174g copper nitrate and 0.1718g indium nitrate, and ultrasonicate for 10min to make a uniform electrolyte.

[0042] 2) In a temperature-controllable growth chamber, use the surface oxidized silicon wafer as the substrate, place two copper foil electrodes with a thickness of about 30 μm in parallel on the substrate, and the distance between the two electrodes is 5-10mm, and drop electrolyte between the electrodes, cover On the coverslip, blot excess electrolyte solution from the edge of the substrate with filter paper.

[0043] 3) Use a low-temperature constant temperature circulator and a semiconductor refrigeration element to refrigerate and freeze the electrolyte, so that the ice layer evenly covers the substrate, and lower the growth temperature to minus 3.5 degrees for 20 minutes.

[0044] 4) Apply a 0.5Hz square wave voltage (0.8V-1.4V) across the electrodes to make Cu 2 O and I...

Embodiment 3

[0049]1) Use deionized water, adjust the pH value to 2.0 with nitric acid, take 30mL, add 0.2174g copper nitrate and 0.1718g indium nitrate, and sonicate for 10min to make a uniform electrolyte.

[0050] 2) In a temperature-controllable growth chamber, use the surface oxidized silicon wafer as the substrate, place two copper foil electrodes with a thickness of about 30 μm in parallel on the substrate, and the distance between the two electrodes is 5-10mm, and drop electrolyte between the electrodes, cover On the coverslip, blot excess electrolyte solution from the edge of the substrate with filter paper.

[0051] 3) Use a low-temperature constant temperature circulator and a semiconductor refrigeration element to freeze the electrolyte, so that the ice layer evenly covers the substrate, and reduce the growth temperature to minus 3.5 degrees for 20 minutes.

[0052] 4) Apply a 0.5Hz square wave voltage (0.8V-1.4V) across the electrodes to make Cu 2 O and In(OH) 3 Periodic alt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com