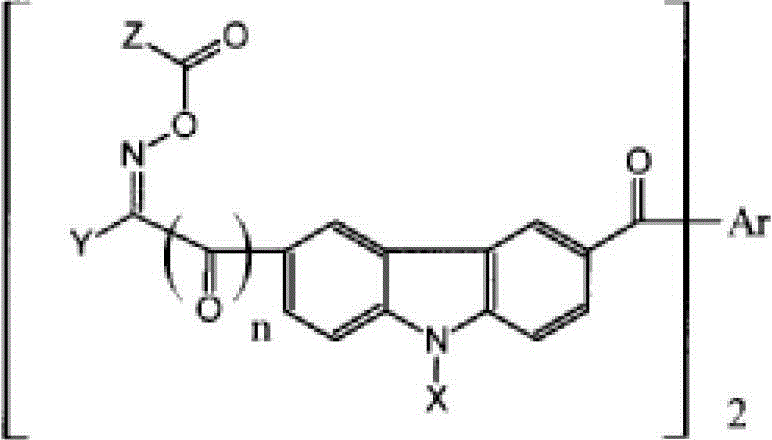

Photocurable resin composition, dry film, cured article, and printed wiring board

A technology of photocurable resin and composition, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve problems such as hindering photoreaction, difficult high filling, lower resolution, etc., to achieve excellent resolution, Excellent heat and cold shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

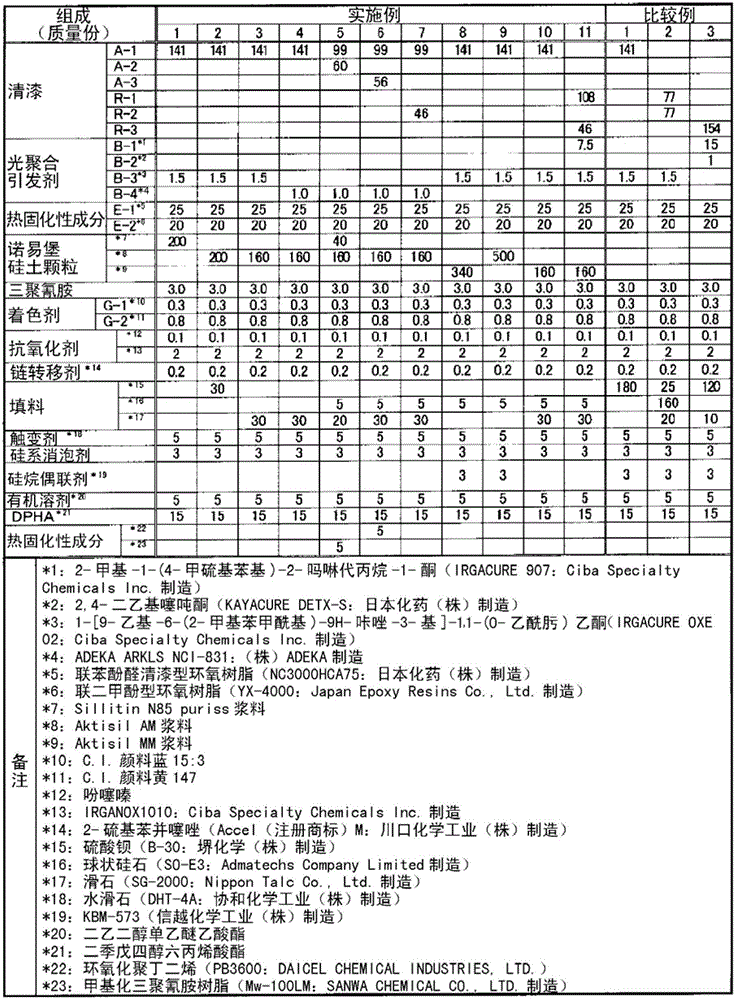

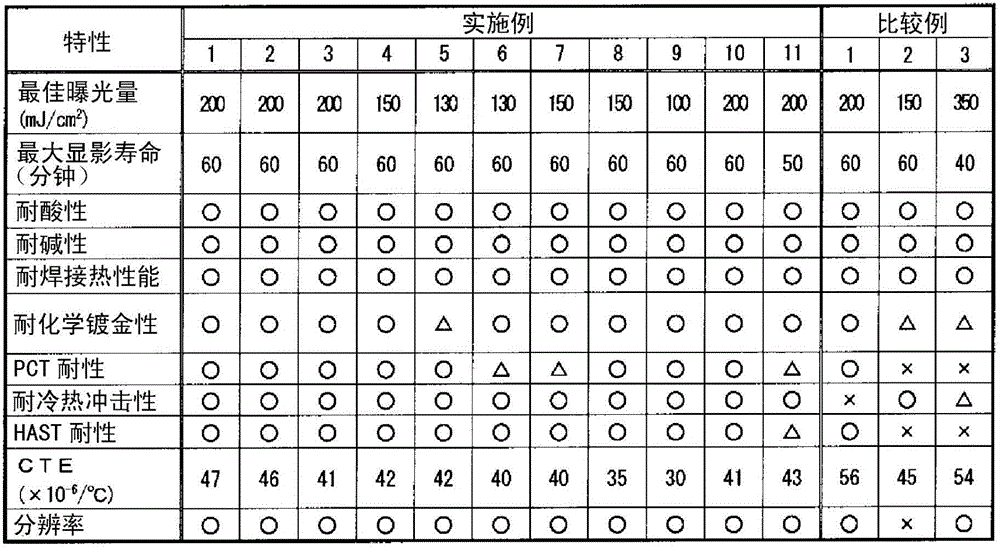

[0184] The present embodiment will be specifically described below by showing examples and comparative examples, but the present invention is of course not limited to the following examples. In addition, "parts" and "%" described below are all mass standards unless otherwise stated.

[0185] (Synthesis of carboxyl-containing resins)

Synthetic example 1

[0187] Add 119.4 g of novolak-type cresol resin (manufactured by Showa Polymer Co., Ltd., trade name: Shonol (registered trademark) CRG951, OH equivalent: 119.4), 1.19g of potassium hydroxide and 119.4g of toluene, nitrogen replacement was carried out in the system while stirring, and the temperature was raised.

[0188] Then, slowly drop 63.8g of propylene oxide, at 125~132℃, 0~4.8kg / cm 2 The reaction was carried out for 16 hours. Thereafter, it was cooled to room temperature, and 1.56 g of 89% phosphoric acid was added and mixed in the reaction solution to neutralize potassium hydroxide to obtain an epoxy resin with a non-volatile content of 62.1% and a hydroxyl value of 182.2 g / eq. Propane reaction solution. An average of 1.08 moles of alkylene oxide was added per 1 equivalent of phenolic hydroxyl group.

[0189] Then, the alkylene oxide reaction solution of 293.0g gained novolak type cresol resin, 43.2g acrylic acid, 11.53g methanesulfonic acid, 0.18g methyl hydroquinon...

Synthetic example 2

[0193] In a 5-liter detachable flask equipped with a thermometer, a stirrer, and a reflux cooler, 1245 g of polycaprolactone diol (manufactured by DAICEL CHEMICAL INDUSTRIES, LTD., trade name: PLACCEL (registered trademark) 208, molecular weight 830), 201 g dimethylol propionic acid as dihydroxy compound with carboxyl groups, 777 g isophorone diisocyanate as polyisocyanate and 119 g acrylic acid-2- Hydroxyethyl ester, and 0.5 g each of p-methoxyphenol and di-tert-butylhydroxytoluene.

[0194] Heating to 60°C while stirring was stopped, and 0.8 g of dibutyltin dilaurate was added. When the temperature in the reaction vessel begins to drop, heat it again, continue stirring at 80°C, and confirm the absorption spectrum of the isocyanate group (2280cm -1 ) disappears, the reaction ends, and a viscous liquid urethane acrylate compound is obtained. Next, the obtained urethane acrylate compound was adjusted to non-volatile matter=50 mass % using carbitol acetate.

[0195] In this w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com