Method for synthesizing hexamethyldisilazane

A technology of hexamethyldisilazane and hexamethyldisiloxane, which is applied in the field of hexamethyldisilazane synthesis, can solve the problems of reduced yield of the target product, low product purity and yield, and achieve The effect of short reaction time, low rectification energy consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 630ml of trimethylchlorosilane, 250ml of hexamethyldisiloxane, 500ml of benzene, and 500ml of xylene into a reaction kettle equipped with a stirrer, thermometer, and pressure gauge, and stir evenly. Ammonia gas is introduced to carry out the ammoniation reaction, and the change of the state of the material in the flask is carefully observed during the process of passing ammonia gas. Strictly control the feeding rate of ammonia gas, and the reaction rate should not be too fast, so as to prevent the salt particles from wrapping trimethylchlorosilane. Control the reaction temperature to ≤80°C and the reaction pressure to ≤0.2Mpa. After the ammoniation reaction is finished, the material is cooled to 35° C., and 800 ml of water is added for the first water washing. After washing, let it stand for 5 minutes, and separate the phases to remove the lower layer of NH 4 Cl aqueous solution. Add 400 ml of 30% potassium hydroxide solution to wash the organic phase, let stand ...

Embodiment 2

[0016] Add 630ml of trimethylchlorosilane, 250ml of hexamethyldisiloxane, and 1000ml of xylene into a reaction kettle equipped with a stirrer, thermometer, and pressure gauge, and stir evenly. Ammonia gas is introduced to carry out the ammoniation reaction, and the change of the state of the material in the flask is carefully observed during the process of passing ammonia gas. Strictly control the feeding rate of ammonia gas, and the reaction rate should not be too fast, so as to prevent the salt particles from wrapping trimethylchlorosilane. Control the reaction temperature to ≤80°C and the reaction pressure to ≤0.2Mpa. After the ammoniation reaction is finished, the material is cooled to 35° C., and 800 ml of water is added for the first water washing. After washing, let it stand for 5 minutes, and separate the phases to remove the lower layer of NH 4 Cl aqueous solution. Add 400 ml of 10% sodium hydroxide solution to wash the organic phase, let stand for 5 minutes after ...

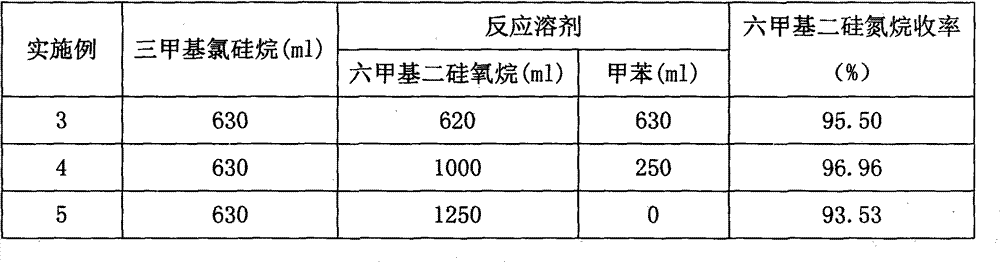

Embodiment 3、4、5

[0018] Similar to Example 2, adopting different mixed solvents to react, the experimental results are as follows:

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com