Hydrophobic coating, preparation method thereof, antenna housing and antenna system

A hydrophobic, radome technology, applied in antifouling/underwater coatings, antennas, coatings, etc., can solve the problems of large dielectric loss, complex process, affecting the electrical performance of the antenna, avoid snow accumulation, and simple process , the effect of good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

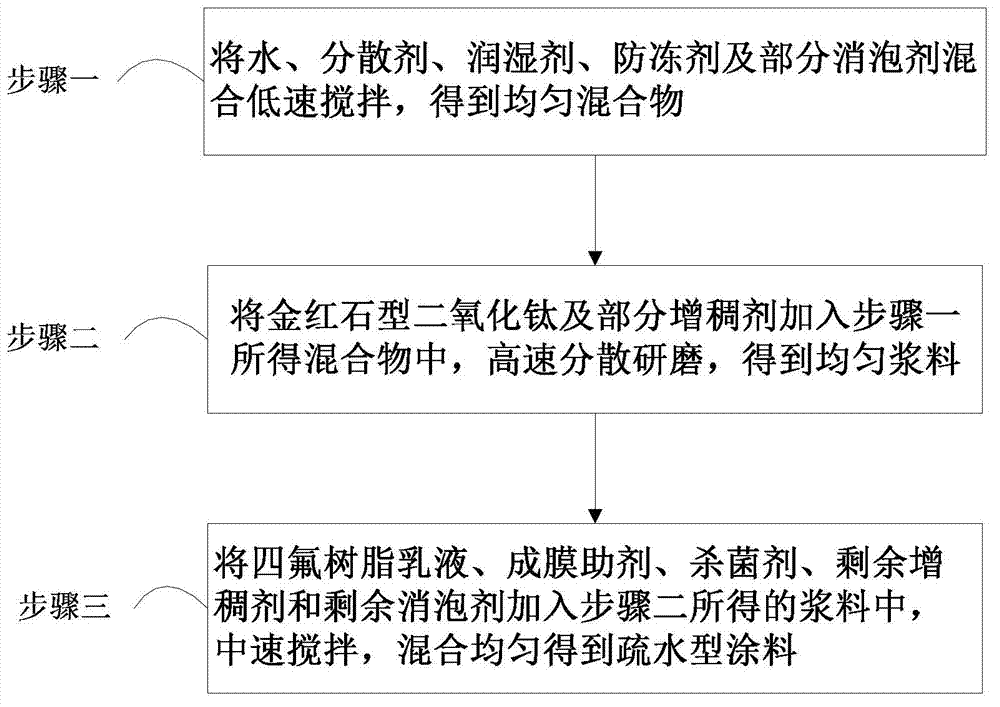

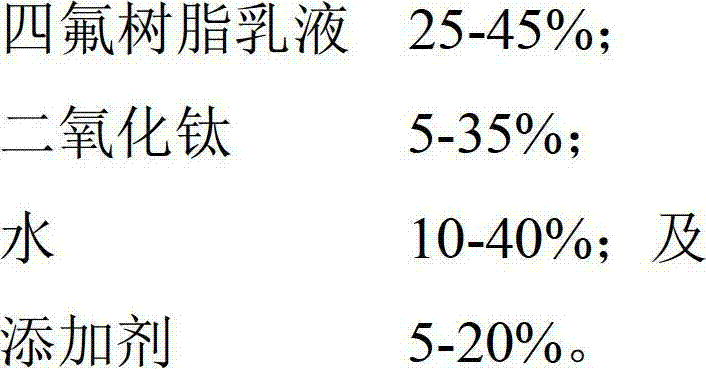

[0025] Such as figure 1 As shown in the flow chart of the preparation method of the hydrophobic coating of the present invention, the preparation method of the above-mentioned hydrophobic coating comprises the following steps:

[0026] Step 1. Mix water, dispersant, wetting agent, antifreeze and part of defoamer and stir at low speed to obtain a uniform mixture.

[0027] Step 2: Add rutile titanium dioxide and part of the thickener to the mixture obtained in Step 1, disperse and grind at a high speed to obtain a uniform slurry.

[0028] Step 3: Add tetrafluororesin emulsion, film-forming aid, bactericide, remaining thickener and remaining defoamer to the slurry obtained in Step 2, stir at a medium speed, and mix evenly to obtain a hydrophobic coating.

[0029] Low-speed stirring in the above preparation method means that the rotating speed of the stirring blade is between 500 rpm-800 rpm, high-speed stirring means that the rotating speed of the stirring blade is between 1500 ...

Embodiment 1

[0036] Hydrophobic coating, its formulation ratio is:

[0037] name

Content (mass percentage)

name

Content (mass percentage 0

PTFE emulsion

45

27.2

Deionized water

10

TRITON TM X-405

0.3

Acrylic acid sodium salt dispersant

0.3

6

Hydrophobic Modified Alkali Swellable Emulsion

0.3

10

0.7

Isothiazolinone fungicides

0.2

[0038] Step 1. Add 10% of deionized water, 0.3% of acrylic acid sodium salt dispersant, 0.3% of TRITONTM X-405 wetting agent, 6% of propylene glycol and 0.3% of silicone defoamer in order according to the above mass, mix and stir for 10 minutes at low speed to obtain Mix well.

[0039] Step 2: Add 27.2% rutile titanium dioxide and 0.2% hydrophobically modified alkali-swellable emulsion to the mixture obtained in step 1, disperse and grind at hig...

Embodiment 2

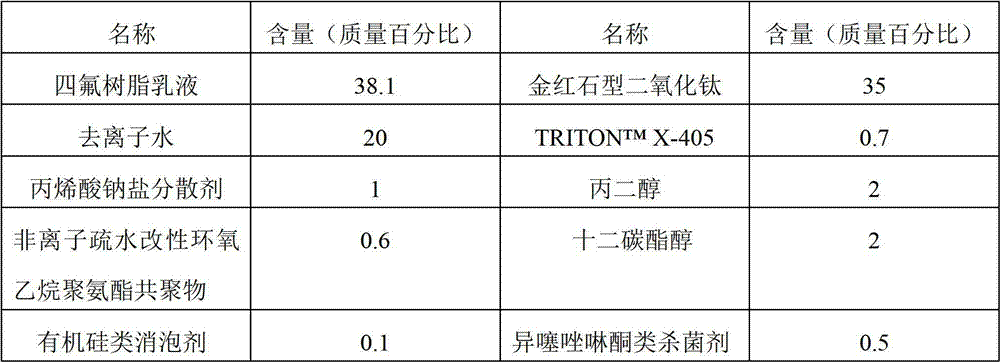

[0043] Hydrophobic coating, its formulation ratio is:

[0044]

[0045] Step 1. Add 20% deionized water, 1% acrylic acid sodium salt dispersant, TRITON TM Mix 0.7% X-405 wetting agent, 2% propylene glycol and 0.05% silicone defoamer and stir at low speed for 5 minutes to obtain a homogeneous mixture.

[0046] Step 2: Add 35% rutile titanium dioxide and 0.3% non-ionic hydrophobically modified ethylene oxide polyurethane copolymer to the mixture obtained in step 1, disperse and grind at high speed for 30 minutes to obtain a uniform slurry.

[0047] Step 3. Add 38.1% of tetrafluororesin emulsion, 2% of dodecyl alcohol, 0.5% of isothiazolinone fungicide, 0.3% of non-ionic hydrophobic modified ethylene oxide polyurethane copolymer, and silicone defoamer Add 0.05% to the above homogeneous slurry, stir for 20 minutes at a medium speed, and get a hydrophobic coating after mixing evenly.

[0048] The hydrophobic coating of the invention can be coated on the surface of the radome,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com