Biological compound flocculant and application thereof

A microbial flocculant and flocculant technology, applied in the field of water treatment, can solve problems such as insufficient charge density, unstable solution viscosity, and insufficient molecular weight, etc., and achieve low cost, improved flocculation effect, and high turbidity removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

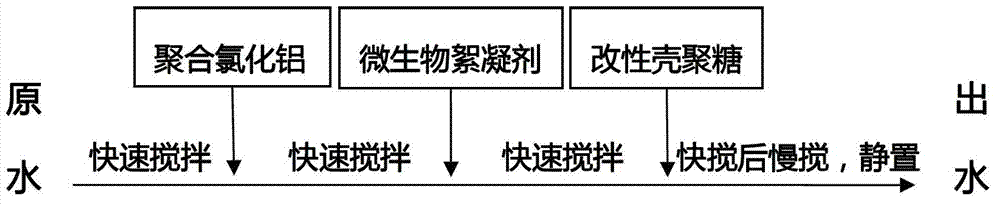

[0049] Treatment of Kaolin Suspension with Biological Composite Flocculant

[0050] (1) Polyaluminum chloride (PAC) was purchased from Henan Zhengzhou Yisheng Chemical Co., Ltd., Al 2 o 3 The content is 23.30%, and it is prepared into a 5g / L solution when used.

[0051] (2) Microbial flocculant (MBF) is a microbial flocculant produced by the fermentation of the original variety of Aspergillus fumigatus, and it is prepared into a 2.0g / L solution before use.

[0052] (3) Preparation of modified chitosan solution (CAD): Firstly, 3 g of chitosan (CTS) was dissolved in 140 mL of 2% acetic acid solution, the reaction temperature was 50 ° C, nitrogen gas was introduced, and stirring was started. After stirring for 5 minutes, the chitosan was dissolved, and 6 milliliters of 5 mmol / L ammonium persulfate solution was slowly added dropwise. After 15 minutes, accurately weigh 7.00 g of acrylamide, place it in a three-necked flask, and start recording the reaction time. After adding ac...

Embodiment 2

[0060] Treatment of Chlorella Suspension with Biological Compound Flocculant

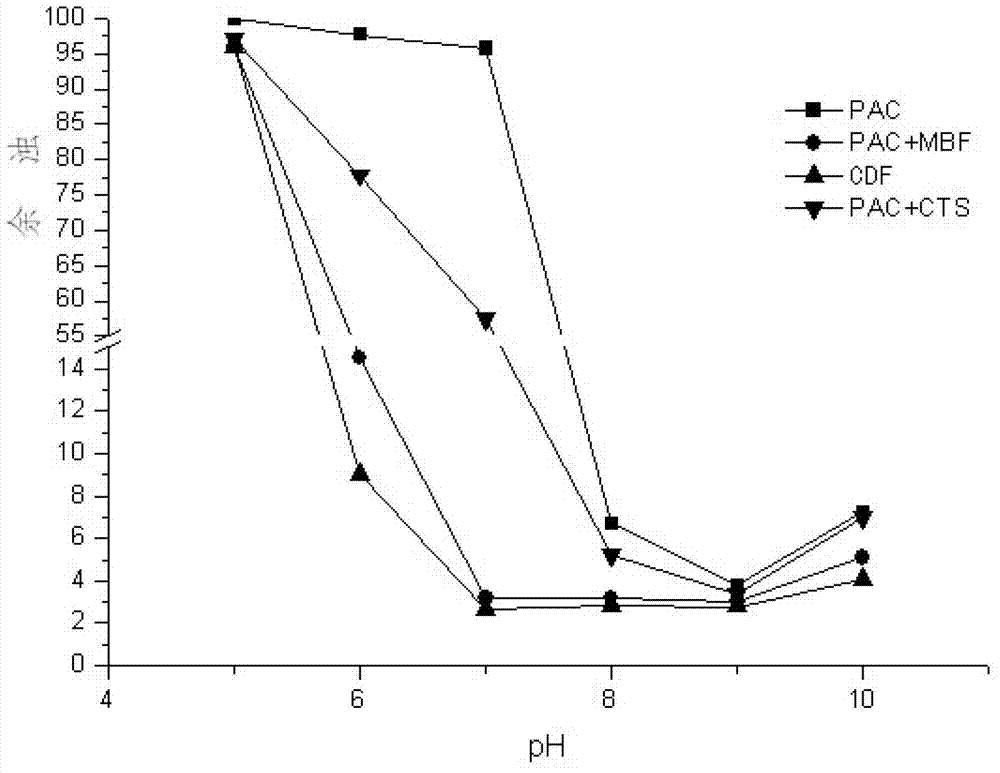

[0061] The green algae culture solution was diluted to a suspension with a turbidity of 7.5 NTU and a pH of 7.63. Polyaluminum chloride was used as coagulant to test the flocculation effect of biocomposite flocculant.

[0062] The dosage of polyaluminum chloride is 3mg / L (as Al 2 o 3 count). The dosage of biological compound flocculant (MBF, CAD mass ratio is 5:3) is 0, 0.5, 1.0, 1.5, 2.0, 3.0, 4.0mg / L. The flocculation process is as described in Example 1. Experimental results such as Figure 5 ,Depend on Figure 5 It can be seen that when the dosage of microbial flocculant and modified chitosan is small (<1mg / L), as the dosage increases, the flocculation effect becomes better, and the flocculation effect becomes better when the dosage exceeds 1.5mg / L. The effects start to get worse. When adding 3mg / L of polychlorination and 1.5mg / L of microbial flocculant and modified chitosan, the turbidi...

Embodiment 3

[0064] Treatment of Tobacco Wastewater with Biological Compound Flocculants

[0065] The wastewater from the tobacco production workshop of China Tobacco Group in Guangzhou has a COD of about 100mg / L, a turbidity of 22.0NTU, and a raw water pH of 6.5, which is adjusted to 7.65 by adding sodium hydroxide solution. Polyaluminum chloride was used as coagulant to test the flocculation effect of biocomposite flocculant.

[0066] The dosage of polyaluminum chloride is 3mg / L (as Al 2 o 3 count). The dosage of biological compound flocculant (MBF, CAD mass ratio is 5:3) is 0, 0.5, 1.0, 1.5, 2.0, 3.0mg / L. The flocculation process is as described in Example 1. The experimental results are as follows Figure 5 ,Depend on Figure 5 It can be seen that the flocculation effect is the best when the polyaluminum chloride is added at 3.0mg / L, and the microbial flocculant and modified chitosan are added at 1.5mg / L, which can reduce the turbidity of wastewater from 22.0NTU to 0.85NTU. Effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com