Degradable Fe-Mn-C ternary iron alloy material and its application

A fe-mn-c, ferroalloy technology, applied in medical science, surgery, etc., can solve the problem of low degradation speed, achieve low magnetic properties, long plasma recalcification time, and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

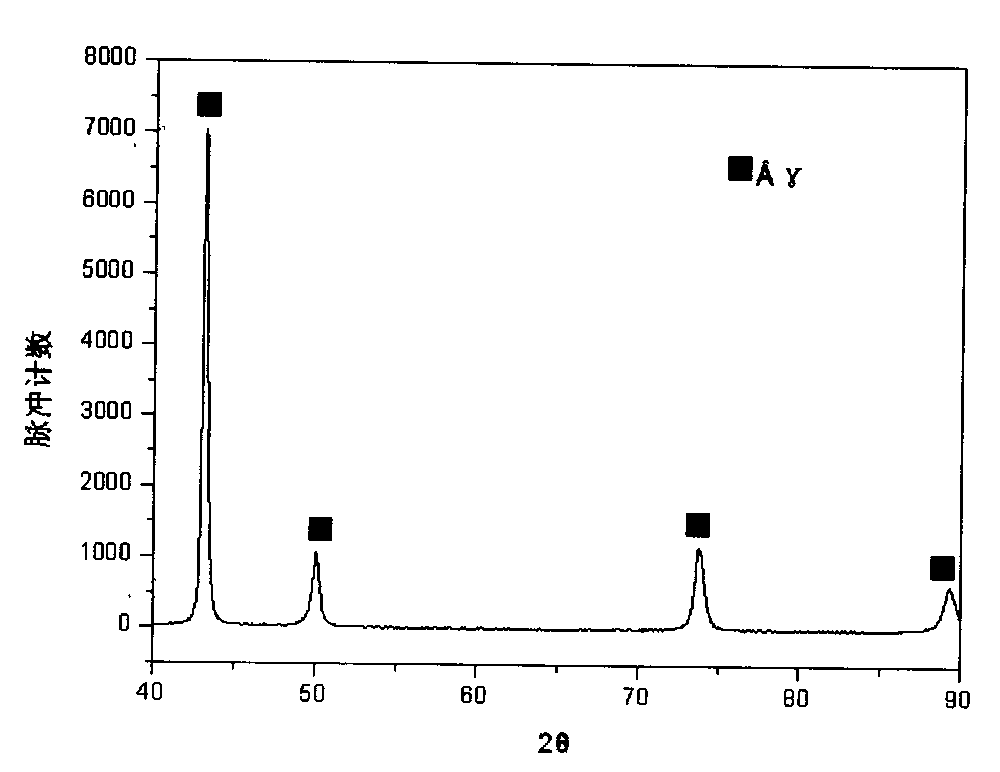

[0020] Fe-Mn-C ternary iron alloy, the mass percentages are: Mn: 30%, C: 1%, the rest is Fe, expressed as Fe-30Mn-1C. Ferroalloy ingots are made by vacuum induction melting. After the ingots are kept at 1050°C for 1 hour, they are forged, air-cooled after forging, and finally forged into round rods with a diameter of Ф25mm.

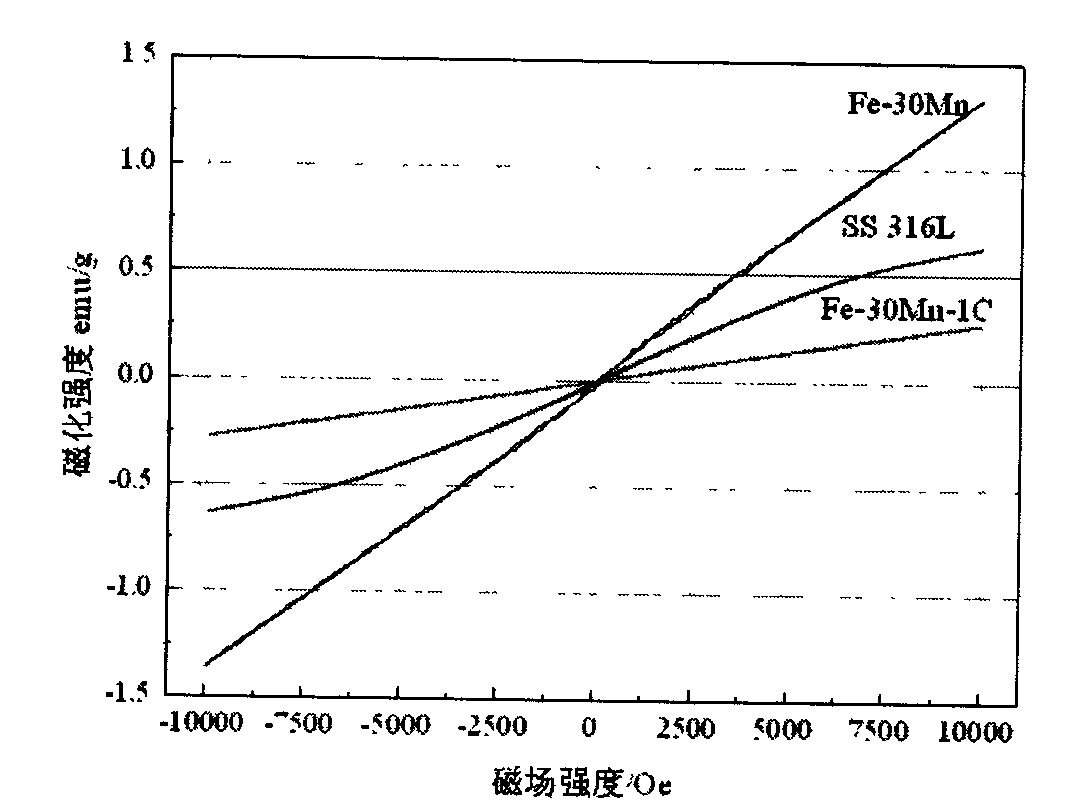

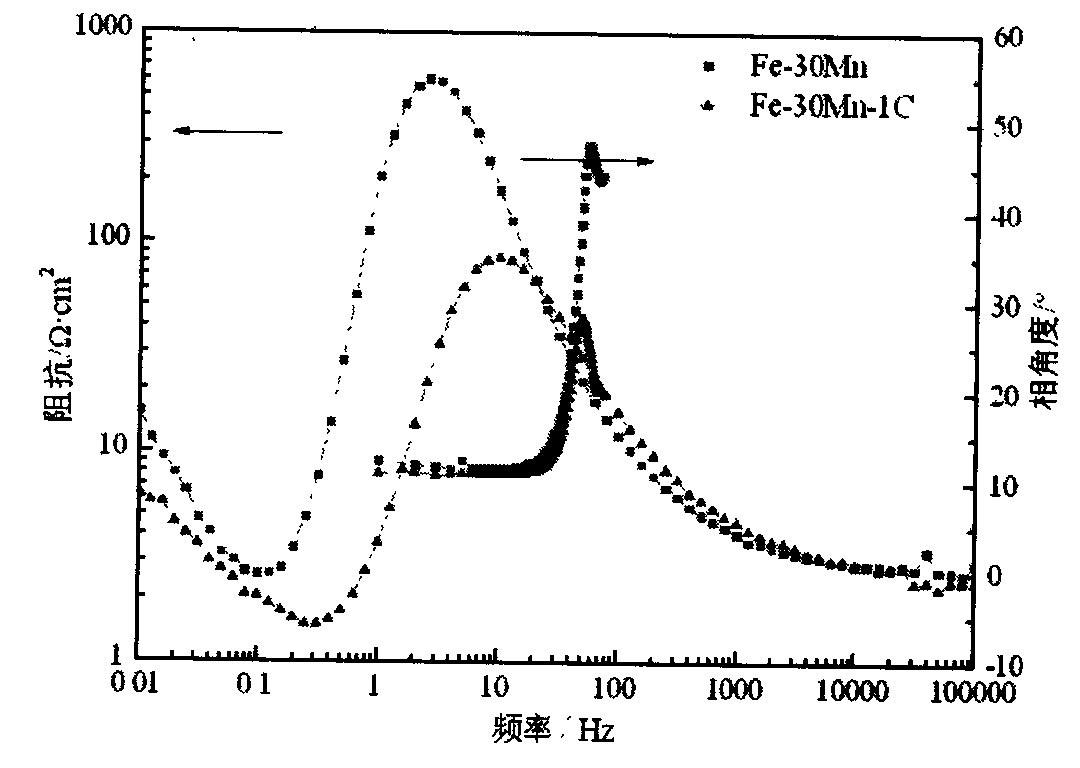

[0021] The forged ferroalloy is processed into a tensile sample of M10Ф5×25mm, and the mechanical properties of the material are tested on the AG-100kNG mechanical testing machine according to the GB / T 228-2002 standard. The tensile strength is 1010MPa, and the yield strength is 373MPa. The elongation was 88%. Electrochemical impedance spectroscopy in saline at 37°C as figure 1 As shown, compared with Fe-30Mn alloy, Fe-30Mn-1C alloy has lower polarization resistance, indicating its higher degradation rate in physiological environment. The immersion experiment in physiological saline showed that the degradation rate of the alloy was as high as 0.20mm / yea...

Embodiment 2

[0025] The Fe-Mn-C ternary iron alloy has the following mass percentages: Mn: 10%, C: 0.8%, and the balance is Fe. Ferroalloy ingots are made by vacuum induction melting. After the ingots are kept at 1050°C for 1 hour, they are forged, air-cooled after forging, and finally forged into round rods with a diameter of Ф25mm.

[0026] The forged iron alloy is processed into a tensile sample of M10Ф5×25mm, and the mechanical properties of the material are tested on the AG-100kNG mechanical testing machine according to the GB / T 228-2002 standard. The tensile strength is 980MPa, and the yield strength is 310MPa. The elongation is 80%. The immersion experiment in physiological saline showed that the degradation rate of the alloy was as high as 0.18mm / year, and the degradation rate decreased to 0.13mm / year after 14 days, which has a relatively high degradation rate. According to the evaluation method of ISO10993, the cytotoxicity of the material in this example is grade 1, and the hemo...

Embodiment 3

[0028] The Fe-Mn-C ternary iron alloy has the following mass percentages: Mn: 40%, C: 2%, and the balance is Fe. Ferroalloy ingots are made by vacuum induction melting. After the ingots are kept at 1050°C for 1 hour, they are forged, air-cooled after forging, and finally forged into round rods with a diameter of Ф25mm.

[0029] The forged iron alloy is processed into a tensile sample of M10Ф5×25mm, and the mechanical properties of the material are tested on the AG-100kNG mechanical testing machine according to the GB / T 228-2002 standard. The tensile strength is 1035MPa, and the yield strength is 320MPa. The elongation is 75%. The immersion experiment in physiological saline showed that the degradation rate of the alloy was as high as 0.23mm / year, and the degradation rate decreased to 0.18mm / year in 14 days, which has a higher degradation rate. According to the evaluation method of ISO10993, the cytotoxicity of the material in this example is grade 1, and the hemolysis rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com