Compound-function wallpaper and preparation method thereof

A composite function and wallpaper technology, which is applied in covering/lining, construction, building structure, etc., can solve the problems of flame retardant wallpaper moisture regain, wallpaper flame retardant is difficult to meet fire protection requirements, and affects performance, etc., to achieve low moisture regain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

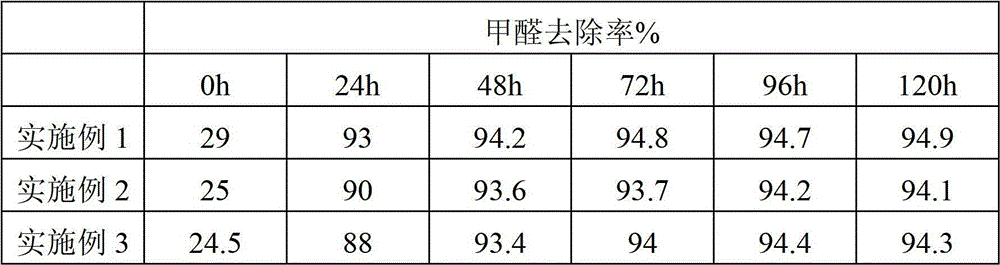

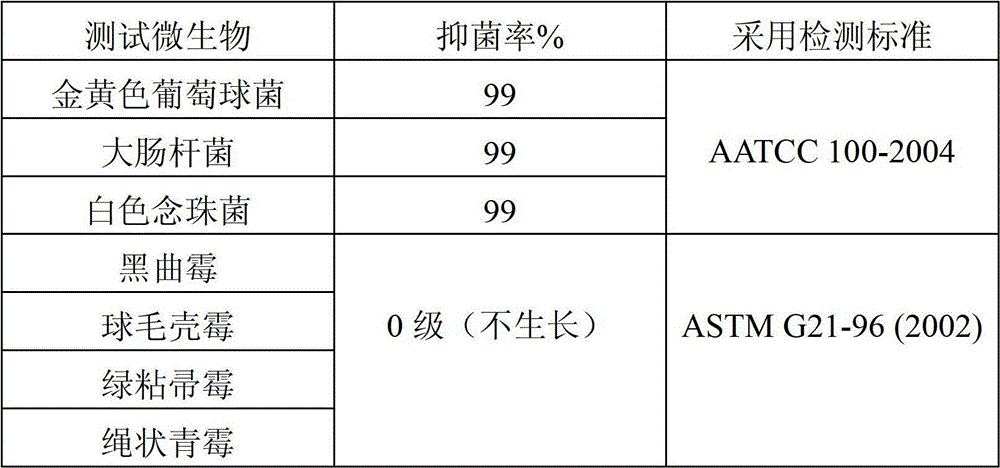

[0043] Embodiment 1, prepare composite functional wallpaper

[0044] (1) Soak the non-woven fabric in the flame retardant finishing solution for 5 minutes, take it out and dry it at 100°C for 3 minutes to obtain the matrix layer; wherein, the composition of the flame retardant finishing solution is: 20 parts of diguanidine hydrogen phosphate , 3 parts of penetrating agent Lutensol XP-50 and 77 parts of water, all are parts by weight.

[0045](2) Add 20 parts by weight of 50% ammonium polyphosphate aqueous solution, 15 parts by weight of formaldehyde-removing ultrafine powder, and 3 parts by weight of polyethylene glycol to 61 parts by weight of formaldehyde-free polyurethane, at 1800r / min Stir evenly under the same conditions, then add 1 part by weight of water-based color paste for coloring, adjust to a suitable viscosity with 1 part by weight of hydroxyethyl cellulose, and scrape it on the substrate layer with a flat plate to form an adhesive layer. The gram weight is 30g / m...

Embodiment 2

[0048] Embodiment 2, prepare composite functional wallpaper

[0049] (1) Soak the non-woven fabric in the flame retardant finishing solution for 7 minutes, take it out and dry it at 100°C for 5 minutes to obtain the matrix layer; wherein, the composition of the flame retardant finishing solution is: organophosphorus flame retardant (diguanidine hydrogen phosphate) 25 parts, penetrant JFC 2 parts and water 73 parts, all are parts by weight.

[0050] (2) Add 25 parts by weight (35% aqueous guanylurea phosphoric acid solution), 12 parts by weight of formaldehyde-removing ultrafine powder and 4 parts by weight of polyethylene glycol to 57 parts by weight of formaldehyde-free polyacrylate , Stir evenly under the condition of 2000r / min, then add 1 part by weight of water-based color paste for coloring, adjust to a suitable viscosity with 1 part by weight of hydroxyethyl cellulose, and apply it on the substrate layer with a flat plate to form an adhesive Layer, its grammage is 20g / m...

Embodiment 3

[0053] Embodiment 3, prepare composite functional wallpaper

[0054] (1) Soak the non-woven fabric in the flame retardant finishing solution for 10 minutes, take it out and dry it at 105°C for 5 minutes to obtain the matrix layer; wherein, the composition of the flame retardant finishing solution is: organophosphorus flame retardant (Diguanidine hydrogen phosphate) 30 parts, penetrant XP-501 parts and water 69 parts, all are parts by weight.

[0055] (2) 30 parts by weight of bromine-antimony-based flame retardant powder (a mixture of antimony trioxide and decabromodiphenyl ether in a weight ratio of 1:4), 10 parts by weight of formaldehyde-removing ultrafine powder and 4 parts by weight Add polyethylene glycol to 52.5 parts by weight of formaldehyde-free polyurethane, stir evenly under the condition of 2000r / min, then add 2 parts by weight of water-based color paste for color adjustment, adjust to 0.5 parts by weight of hydroxyethyl cellulose Appropriate viscosity, scrape on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com