Biodiesel oil preparing method

A biodiesel and product technology, applied in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems that have not been successfully realized industrialization, China University of Science and Technology, Petrochemical Science Research Institute, Northwest Agriculture and Forestry Science and Technology University, Liaohe Chemical Plant, Northeast Forestry University, East China University of Science and Technology, Liaoning Provincial Energy Institute, etc. have carried out laboratory research and development, etc., to achieve the effects of high selectivity, good stability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

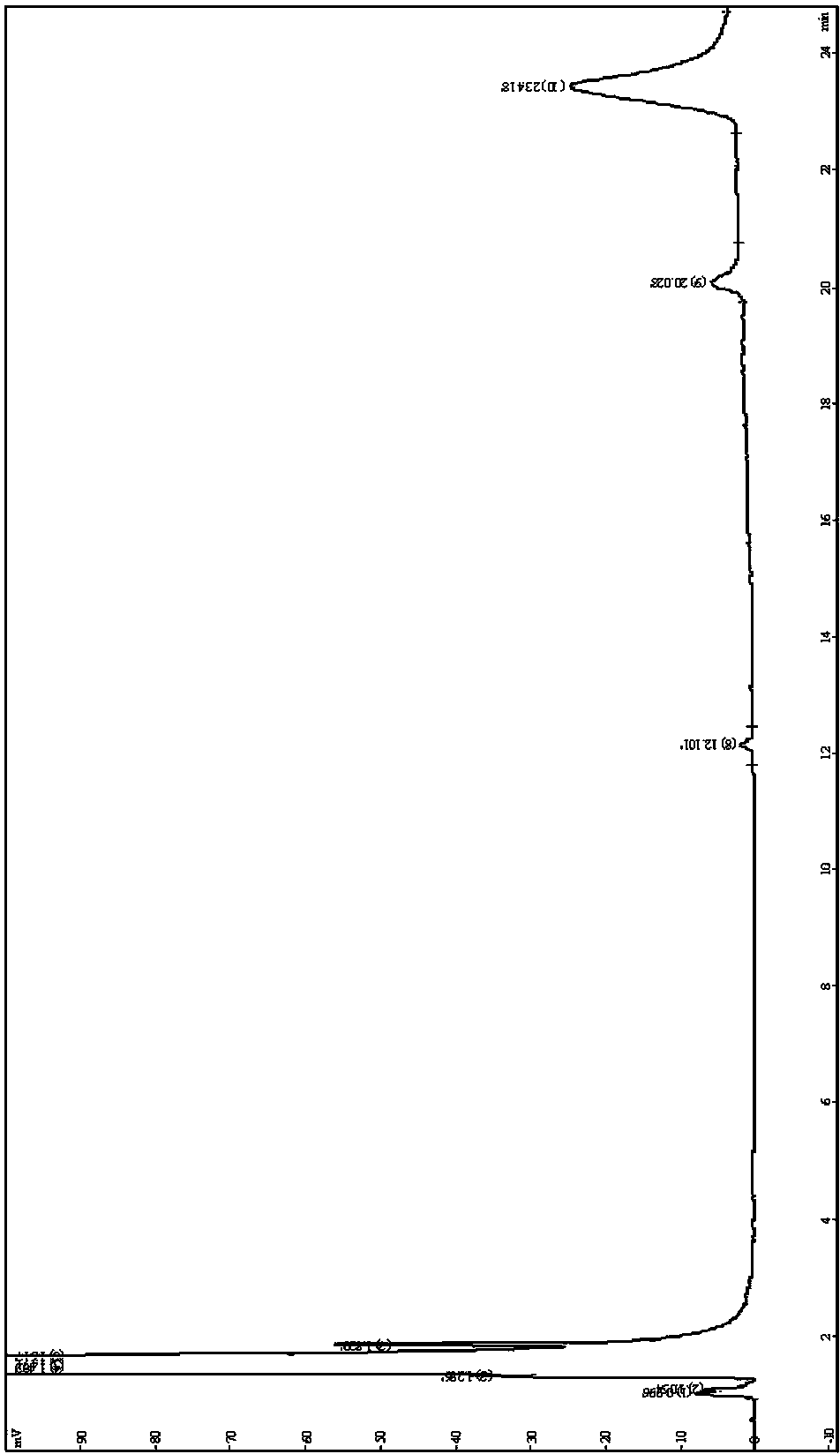

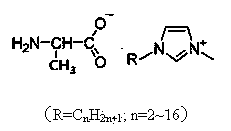

[0012] Take 50 ml of soybean oil and put it into a reaction vessel, preheat it at 30°C for 60 minutes; add ionic liquid (1-ethyl-3-methyl imidazole alanine) in 50 ml of methanol solution, turn on the stirring device, control the rotation speed at 250 r / min, and react violently for 90 minutes; take it out and transfer it to a separatory funnel, and let it stand at room temperature until the system is clearly divided into two layers. Transfer the lower layer substance to another separatory funnel, and add an equal volume of warm water for washing. After the solution is divided into two layers, the upper layer product is the target product. The yield was 80%.

[0013] The target product was detected by gas chromatography, and the results were as follows: figure 1 Shown, show that the target product that adopts the method of the present invention to obtain is mainly methyl linoleate and methyl palmitate.

Embodiment 2

[0015] Take 25 ml of soybean oil and put it into a reaction vessel, preheat it at 50°C for 40 minutes; add ionic liquid (1-butyl-3-methyl imidazole proline) methanol solution 100 ml, turn on the stirring device, control the speed of 100 r / min, and react violently for 60 minutes; take it out and transfer it to a separatory funnel, and let it stand at room temperature until the system is clearly divided into two layers. Transfer the lower layer substance to another separatory funnel, and add an equal volume of warm water for washing. After the solution is divided into two layers, the upper layer product is the target product. The yield was 90%.

[0016] The target product was detected by gas chromatography, which showed that the target product was mainly methyl linoleate and methyl palmitate.

Embodiment 3

[0018] Take 100 ml of soybean oil and put it into a reaction vessel, preheat it at 60°C for 10 minutes; add ionic liquid (1-hexyl-3-methyl imidazolium leucine) methanol solution 500 ml, turn on the stirring device, control the speed of 500 r / min, and react vigorously for 150 minutes; take it out and transfer it to a separatory funnel, let it stand at room temperature, and transfer the Put the substance in the lower layer into another separating funnel, and add an equal volume of warm water to wash it. After the solution is divided into two layers, the product in the upper layer is the target product. The yield was 92%.

[0019] The target product was detected by gas chromatography, which showed that the target product was mainly methyl linoleate and methyl palmitate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com