Lactobacillus casei and application of lactobacillus casei to feed

A technology of Lactobacillus casei and feed, applied in the field of bio-fermentation technology and feed, can solve the problems of low number of viable fermentation bacteria, low enzyme production, slow growth of strains, etc., and achieve good anti-oxidation and antibacterial ability, fermentation activity The effect of increasing the number of bacteria and increasing daily weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

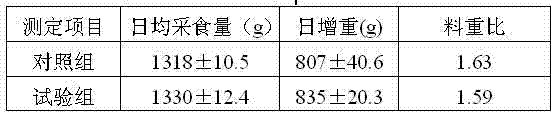

Embodiment 1

[0032] Weigh 5 kg of bean cake powder, 1 kg of rapeseed meal, and 0.1 kg of sunflower seeds, crush them to 20 mesh with a pulverizer, and prepare them as a matrix, add 10.9 kg of water, and add 0.061 kg of cornstarch, 0.0061 kg of ammonium sulfate, and Sodium chloride 0.037kg, stirred evenly, prepared into a solid-state fermentation medium, put into a solid-state fermentation tank, boiled at 100°C for 30min, cooled with sterile cold air for later use; take the above-mentioned Lactobacillus casei seed liquid to account for the total weight of the substrate 1% of the inoculum was inoculated into the above-mentioned solid-state fermentation medium, and the solid-state fermentation conditions were as follows: the initial pH value of the fermentation was 6.0, the product temperature during the fermentation was 25°C, and the fermentation time was 24 hours. Air-dried to obtain a feed additive. The additive is bagged and sealed, and stored in a ventilated, cool and dry place. Adopt M...

Embodiment 2

[0034] Weigh 5kg of bean cake powder and 2kg of rapeseed meal, pulverize them to 30 mesh with a pulverizer, prepare a matrix, add 9kg of water, add 0.21kg of cornstarch, 0.035kg of ammonium sulfate, and 0.049kg of sodium chloride while adding water, and stir Evenly, prepare a solid-state fermentation medium, put it into a solid-state fermentation tank, cook at 100 ° C for 30 minutes, and cool it with sterile cold air for later use; take the above-mentioned Lactobacillus casei seed liquid to account for 2% of the total weight of the substrate. Inoculated in a solid-state fermentation medium, the solid-state fermentation conditions are as follows: the initial pH value of the fermentation is 6.0, the product temperature during the fermentation process is 30°C, the fermentation time is 36h, and after the fermentation is completed, it is air-dried in an air dryer at 40°C to obtain a feed additive . The additive is bagged and sealed, and stored in a ventilated, cool and dry place. ...

Embodiment 3

[0036] Weigh 1000kg of bean cake powder, 200kg of rapeseed meal, and 30kg of sunflower seed meal, pulverize them to 40 meshes with a pulverizer, prepare a matrix, add 1797kg of water, and add 61.5kg of cornstarch, 3.69kg of ammonium sulfate, and Sodium 6.15kg, stir evenly, be mixed with solid-state fermentation medium, put into cement fermentation tank; Get above-mentioned Lactobacillus casei seed liquid to account for the inoculum amount of 3% of described substrate gross weight, inoculate in solid-state fermentation medium, solid-state fermentation The conditions are as follows: the initial pH value of the fermentation is 6.5, the product temperature during the fermentation is 35°C, the fermentation time is 24 hours, and after the fermentation is completed, it is air-dried in an air dryer at 30°C to obtain the feed additive. The additive is bagged and sealed, and stored in a ventilated, cool and dry place. Adopt MRS solid culture medium pouring plate counting method to count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com