Macromolecular organic silicon modifier as well as preparation method and application thereof in surface treatment of hydroxide flame retardant

A hydroxide and surface treatment technology, applied in the direction of dyeing organosilicon compound treatment, fibrous filler, etc., can solve the problems of little improvement effect of interface bonding force, short molecular chain, limited modification effect, etc., and achieve easy popularization and application. , low cost and controllable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

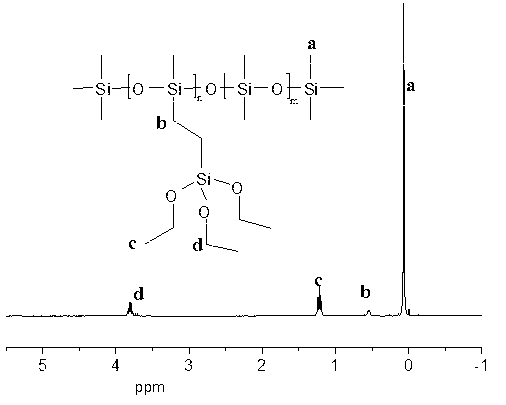

[0039] First, 17.1 g of vinyltriethoxysilane, 0.01 g of platinum catalyst and 50 mL of toluene were added into a 200 mL four-necked flask, and heated to 130 °C under nitrogen protection. Then, 30 g of hydrogen-containing polysiloxane with a mass fraction of hydrogen of 0.3% was slowly added dropwise into the mixed solution using a constant-pressure dropping funnel, and stirred for 12 hours. After the reaction was complete, toluene and unreacted vinyltriethoxysilane were distilled off under reduced pressure to obtain a transparent product. Wash 5 times with methanol, remove the supernatant, spin out methanol, obtain the purified macromolecular silicone modifier, figure 1 As a silicone macromolecule modifier 1 H-NMR spectrum.

[0040] Disperse 40g of aluminum hydroxide into a mixed solution of 200mL of absolute ethanol and water (the mass ratio of absolute ethanol to water is 9:1), ultrasonically disperse for 1h, add 2g of macromolecular organic Silicon modifier, react at 80°...

Embodiment 2

[0043] This example is the same as Example 1 except for the following features: 60g of aluminum hydroxide is dispersed into a mixed solution of 300mL of absolute ethanol and water, and 3g of a macromolecular organosilicon modifier after hydrolysis at pH=3 for 1h is added, After the reaction, modified aluminum hydroxide is obtained. Adding the modified aluminum hydroxide to the silicone rubber can produce a tensile strength of 5.04MPa, a tear strength of 24.2kN / m, a breaking elongation of 250%, a Shore hardness of 51, and an oxygen index of 35.3. % flame retardant silicone rubber.

[0044] Using the same characteristics as the above examples, when the commonly used silane coupling agent A-151 is used as a modifier, the tensile strength of the silicone rubber obtained with the same formula is 4.83MPa, the tear strength is 23.3kN / m, The elongation at break is 220%, the Shore hardness is 51, and the oxygen index is 35.0%.

Embodiment 3

[0046] This example is the same as Example 1 except for the following features: 80g of aluminum hydroxide is dispersed into a mixed solution of 400mL of absolute ethanol and water, and 4g of a macromolecular organosilicon modifier after hydrolysis at pH=3 for 1h is added, After the reaction, modified aluminum hydroxide is obtained. Adding the modified aluminum hydroxide to the silicone rubber can produce a tensile strength of 4.91MPa, a tear strength of 21.7kN / m, a breaking elongation of 240%, a Shore hardness of 55, and an oxygen index of 37.5. % flame retardant silicone rubber.

[0047] Using the same characteristics as the above examples, when the commonly used silane coupling agent A-151 is used as a modifier, the silicone rubber obtained with the same formula has a tensile strength of 4.58MPa, a tear strength of 21.6kN / m, and a fracture strength of 21.6kN / m. The elongation is 200%, the Shore hardness is 55, and the oxygen index is 37.3%.

[0048] From the results of sev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com