Electrostatic spraying type chlorinated rubber anticorrosive paint and preparation method thereof

A technology of chlorinated rubber and electrostatic spraying, which is applied in the direction of anti-corrosion coatings, rubber derivative coatings, coatings, etc., and can solve the problems that chlorinated rubber anti-corrosion paints cannot be sprayed electrostatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

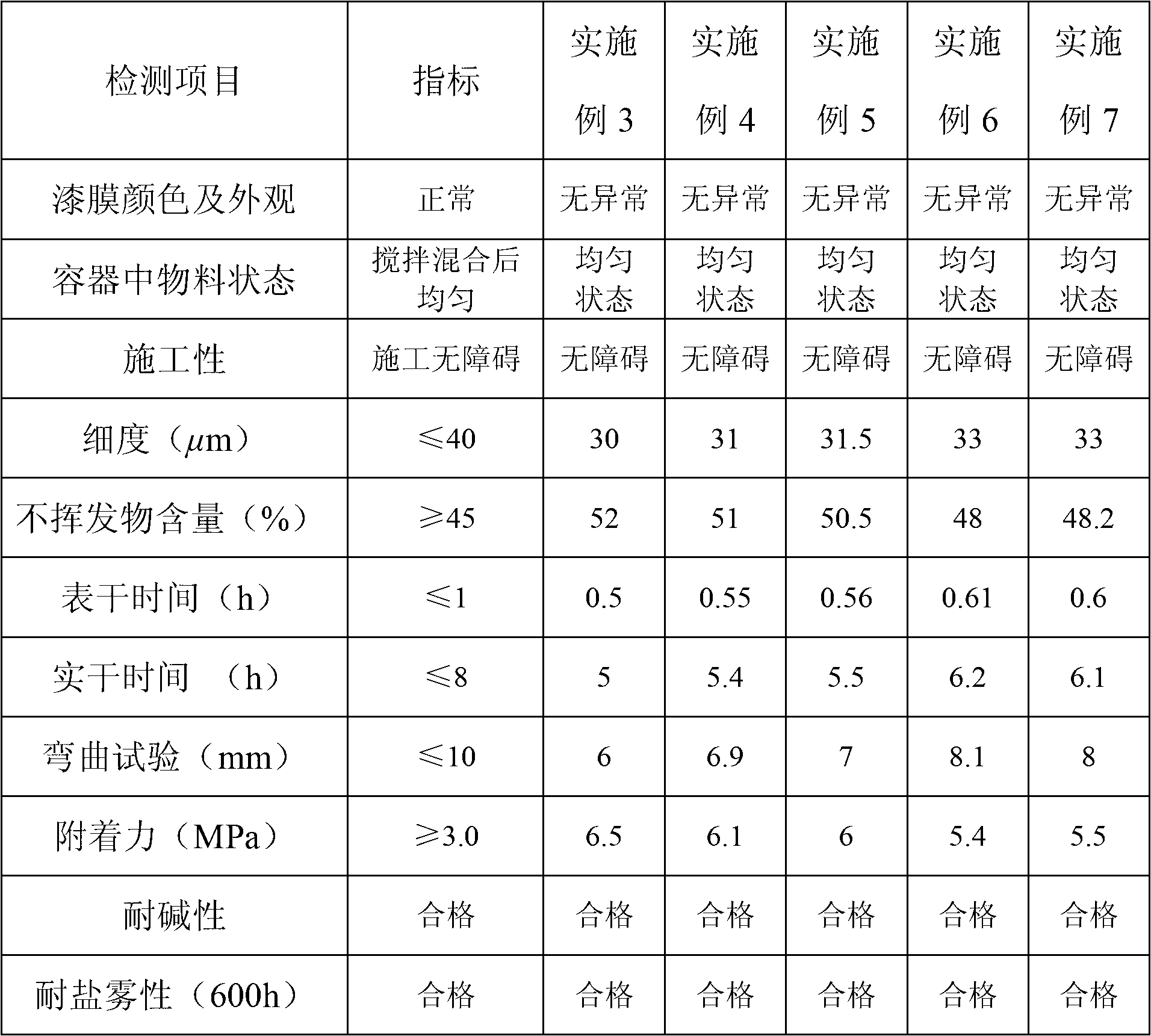

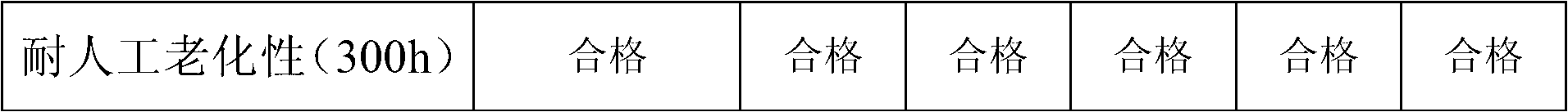

Examples

Embodiment 1

[0098] Preparation of chlorinated rubber fluid:

[0099] According to weight percentage, 40wt% molecular weight is 54000-88000, viscosity is the new solvent method chlorinated rubber of 10-20 centipoise to be dissolved in the mixed solvent of the petroleum xylene of 58wt% and the epichlorohydrin of 2wt%, mix Get even.

[0100] The new solvent-process chlorinated rubber is a product of Xiangshui County Ruize Chemical Co., Ltd., and the model is chlorinated rubber R10-20.

[0101] Described petroleum xylene is the industrial grade petroleum xylene of Wuhan Changqing Chemical Co., Ltd.

[0102] The epichlorohydrin is industrial grade epichlorohydrin of Jiangsu Ruixiang Chemical Co., Ltd.

Embodiment 2

[0104] Preparation of phenolic resin solution:

[0105] According to the weight of 1:1, dissolve 210 modified phenolic resin (Jiangsu Jiangdu Synthetic Resin Factory) in industrial grade petroleum xylene (Wuhan Changqing Chemical Co., Ltd.), and mix evenly.

Embodiment 3

[0107] A kind of electrostatic spraying type chlorinated rubber anticorrosion paint, comprises anticorrosion paint and special electrostatic paint diluent double-component with weight ratio 3:1 uniform mixing; Described anticorrosion paint comprises the following components represented by weight percentage wt %: Chlorinated rubber solution 56wt%, phenolic resin solution 10wt%, chlorinated paraffin-5212wt%, high pigment carbon black 3wt%, composite iron-titanium antirust powder 10wt%, BYK-161 dispersant 0.5wt%, BT-828 organic bentonite 1wt%, petroleum xylene 7.5wt%; the special electrostatic paint thinner includes the following components expressed in weight percent: EA-87 conductive agent (U.S. Elementis Corporation) 5wt%, n-butanol 15wt%, propylene glycol methyl Ether acetate 20wt%, ethyl acetate 60wt%.

[0108] The chlorinated rubber liquid is the product of Example 1.

[0109] Described phenolic resin liquid is the product of embodiment 2.

[0110] The chlorinated paraffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com