Streptomyces roseosporus and method for producing daptomycin by utilizing combined precursor

A technology of Streptomyces roseospora and daptomycin, which is applied in the field of biopharmaceuticals, can solve the problems of resource waste, high production cost, and increased foam, and achieve the effect of reducing resource waste, production cost, and extraction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

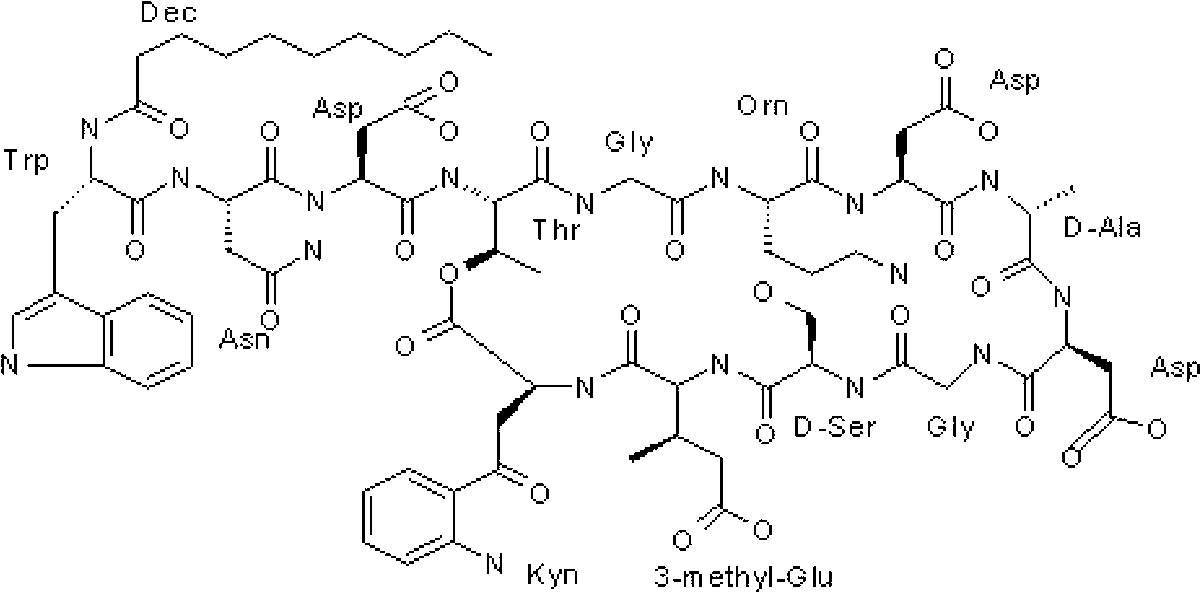

Image

Examples

Embodiment 1

[0033] Streptomyces roseosporus. NTG1206 was used in a 50L fermenter to produce daptomycin by adding capric acid and methyl oleate.

[0034] 1 Preparation of liquid fermentation medium

[0035] Seed medium (g / L): dextrin 25, glucose 5, soybean meal 18, yeast powder 5, KCl0.2, FeSO 4 ·7H 2 O0.001, adjust the pH to 7.2 with 20% NaOH. Sterilize at 121°C for 30min.

[0036] Fermentation medium (g / L): dextrin 50, glucose 1.0, soybean meal powder 20, yeast powder 5.0, sugarcane molasses 7.0, Fe(NH 4 ) 2 (SO 4 ) 2 .6H 2 O0.8, KCl0.2, defoamer 0.5. Adjust the pH to 7.2 with 20% NaOH. Sterilize at 121°C for 30min.

[0037] 2 Fermentation process

[0038] (1) Streptomyces roseosporus. NTG1206 was inoculated on the slant medium, cultured aerobically at 30°C for 10 days, and the mature spores were prepared into glycerol tubes, which were stored at low temperature.

[0039] (2) Inoculate the bacterium solution preserved in step (1) into the seed medium of the shake flask, and sha...

Embodiment 2

[0045] Streptomyces roseosporus. NTG1206 was used in a 50L fermenter to produce daptomycin by adding decanal.

[0046] 1 Culture medium is the same as in Example 1.

[0047] 2 Fermentation process

[0048] In the fermentation process, a 50L fermentation tank has a liquid filling capacity of 30L, and all the other are the same as in Comparative Example 1.

[0049] After 30 hours of fermentation and cultivation, decanal was added at a rate of 0.15 g / L.h.

[0050] Daptomycin was detected by Shimadzu LC-20A liquid chromatograph, and appropriate amount of dextrin and yeast powder solution were added during the fermentation process. The titer of daptomycin was 1470 mg / L after 192 hours of fermentation, and the volume of the fermentation broth was 26 L.

[0051] The precursor was added for 48 hours, and the morphology of the bacteria was observed under a microscope, and no obvious vacuoles and hyphae were broken.

Embodiment 3

[0053] Streptomyces roseosporus. NTG1206 was used in a 50L fermenter to produce daptomycin by adding capric acid and decanal.

[0054] 1 Culture medium is the same as in Example 1.

[0055] 2 Fermentation process

[0056] (1) Streptomyces roseosporus. NTG1206 was inoculated on the slant medium, cultured aerobically at 30°C for 10 days, and the mature spores were prepared into glycerol tubes, which were stored at low temperature.

[0057] (2) Inoculate the bacterium solution preserved in step (1) into the seed medium of the shake flask, and shake and cultivate at 30°C and 230rpm for 30-48h.

[0058] (3) Inoculate the mature bacterial liquid from (2) into the fermentation medium (50L fermenter, liquid volume 35L) according to the inoculum volume of 1-5% of the medium volume of the fermenter. Fermentation conditions: 30°C, ventilation The volume is 1vvm, the stirring speed is 150rpm-350rpm, and the tank pressure is 0.05mpa. The pH was controlled at 6.5 with ammonia water.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com