Micro atomic cavity subjected to negative pressure forming, micro atomic clock chip and preparation method for micro atomic cavity and micro atomic clock chip

A technology of atomic cavity and atomic clock, which is applied in the field of MEMS (micro-electro-mechanical system) manufacturing, can solve the problems of high design requirements, high cost, and complicated assembly of reflective surfaces, and achieve low cost, simple method, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method for negative pressure forming miniature atomic cavities, comprising the following steps:

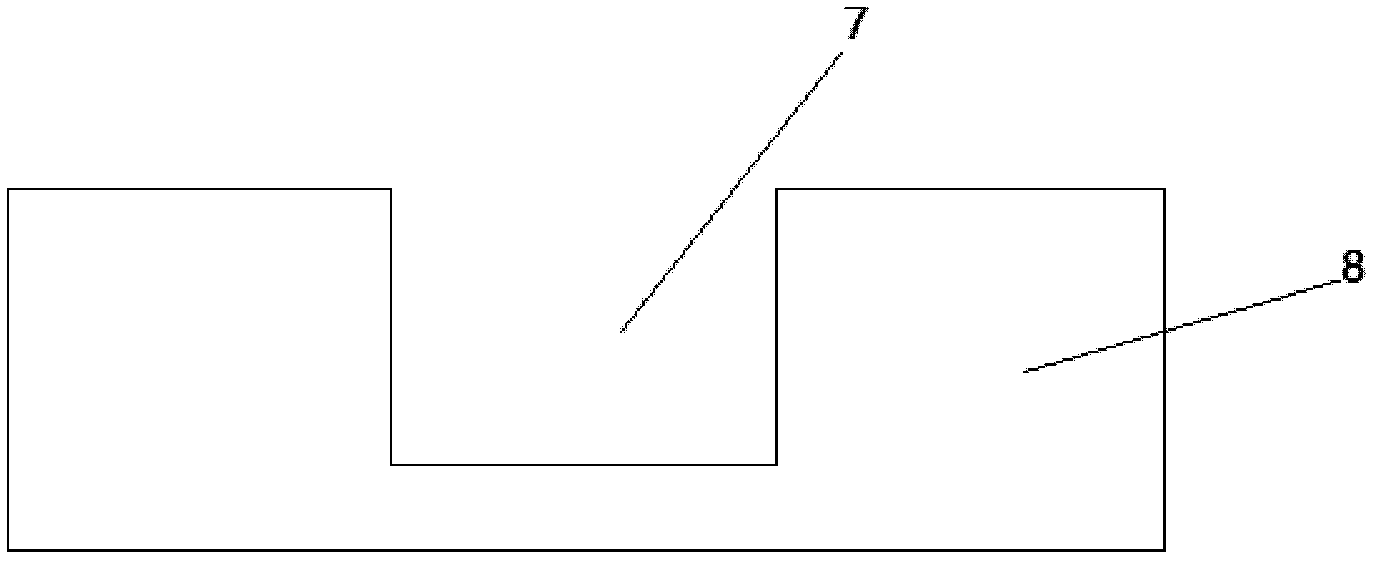

[0042] The first step is to use deep reactive ion etching technology to etch a square deep groove on the silicon wafer to form a silicon mold;

[0043] In the second step, anodically bond the above-mentioned silicon mold with deep grooves and the Pyrex borosilicate glass assembly wafer under vacuum. The anodic bonding conditions are: the temperature is 300-500°C, for example, 300°C, 400°C and 500°C, the voltage is 400-800V, for example, 400V, 600V, and 800V can be selected, so that the borosilicate glass wafer and the above-mentioned deep groove form a sealed cavity;

[0044] The third step is to heat the bonded wafer above the glass softening temperature under an atmospheric pressure, for example, 1270°C, and keep it warm at this temperature for 10-30 minutes, for example, 10min, 20min, 30min , the pressure difference inside and outside the cavity makes the ...

Embodiment 2

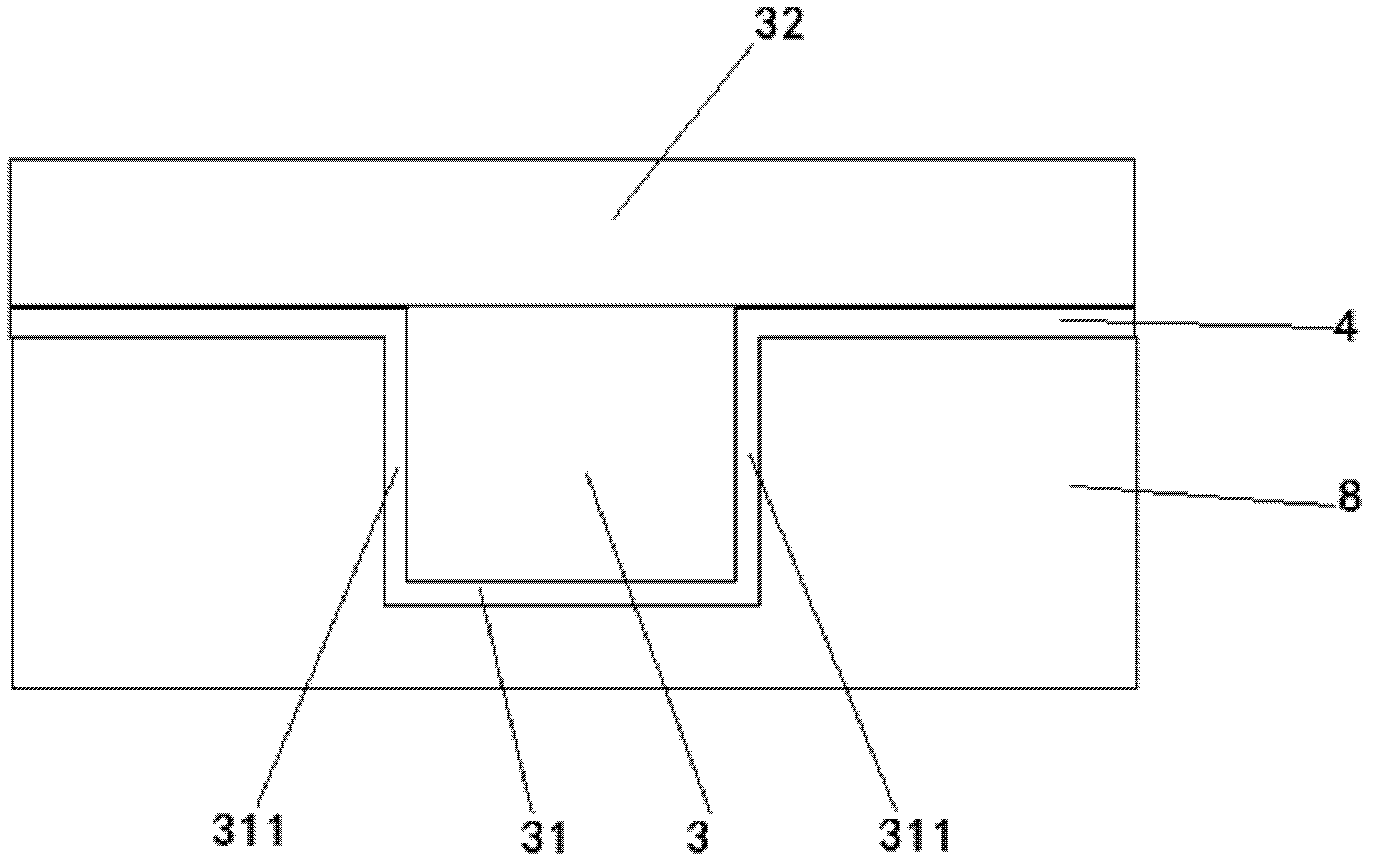

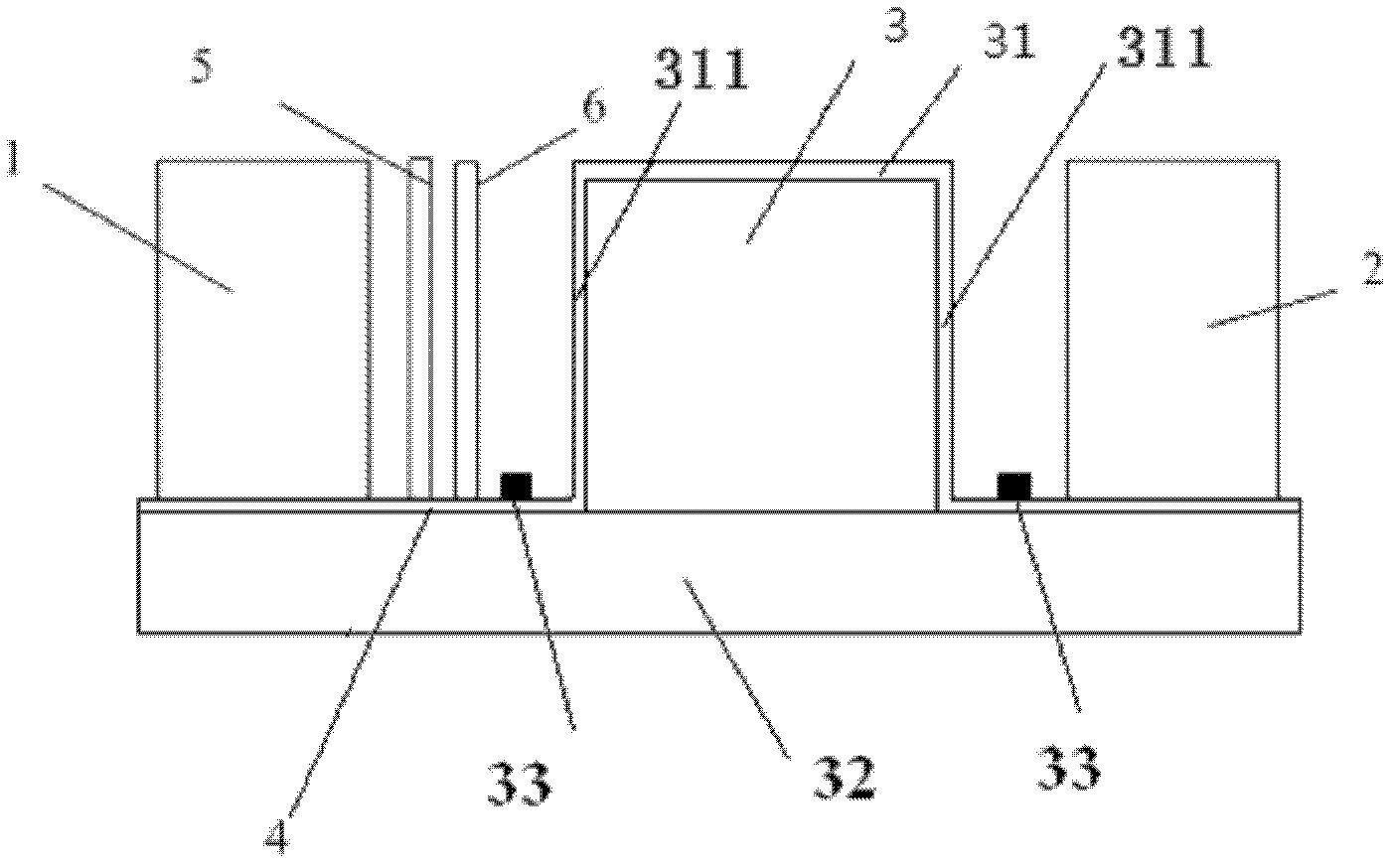

[0048] A miniature atomic clock chip comprises a laser generator, a filter, a quarter wave plate, a laser detector and the miniature atomic cavity prepared by the method, a laser generator, a filter, a quarter wave plate, a laser detector They are all assembled on borosilicate glass assembly wafers, and their centers are on the same optical axis as the center of the glass microcavity. The laser generator is located on the side of the airtight glass atomic cavity with a straight vertical side. A filter and a quarter-wave plate are arranged in sequence between the straight and vertical sides. The laser light emitted by the laser generator passes through the filter and the quarter-wave plate, enters the airtight glass atomic cavity through the straight and vertical sides, and then passes through the glass The other straight and vertical side of the microcavity exits and is detected by a laser detector. A heater is also arranged around the glass microcavity. The above-mentioned hea...

Embodiment 3

[0050] A preparation method for a miniature atomic clock chip, comprising the following steps:

[0051] In the first step, a micro-atomic cavity with straight and vertical sides is prepared by negative pressure forming method;

[0052] In the second step, a heater is prepared on the borosilicate glass assembled wafer around the glass microcavity;

[0053] In the third step, the laser generator, laser detector, filter and quarter-wave plate are respectively assembled on the corresponding positions of the borosilicate glass assembly wafer and are located at the same position as the center of the straight vertical side of the airtight glass atomic cavity. On one optical axis, the laser light emitted by the laser generator can be detected by the laser detector after passing through the filter, the quarter-wave plate and the sealed glass atomic cavity;

[0054] The fourth step is to prepare the pins of the heater, laser generator and laser detector, and connect them to the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com