Corrosion inhibitor for inhibiting chlorine dioxide corrosion and preparation method thereof

A technology of chlorine dioxide and corrosion inhibitor, which is applied in the field of metal preservative preparation, can solve the problems of impractical application, impracticality, and reduced activity of biological enzymes, and achieves the effect of excellent thermal stability and a wide range of application systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

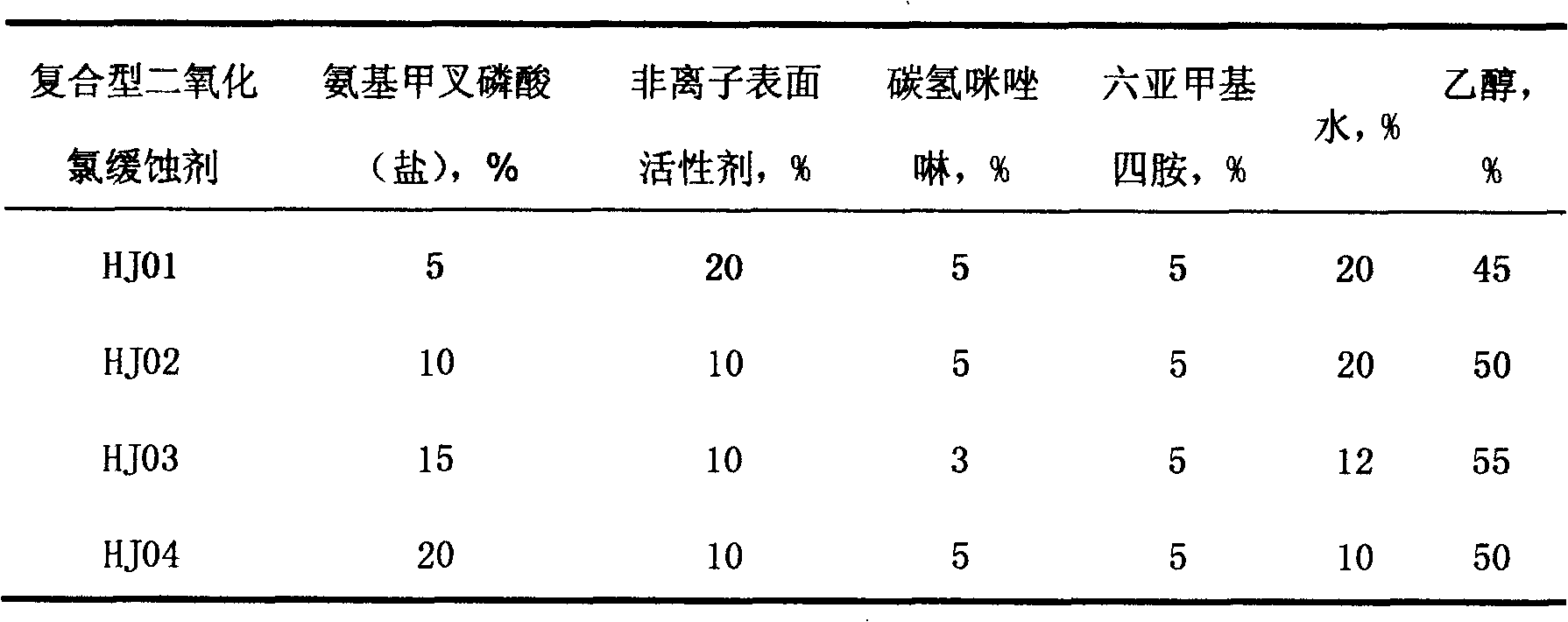

[0021] Chlorine dioxide corrosion inhibitors were prepared according to the weight of each component given in Table 1, and the raw materials in Table 1 were added to the reaction kettle in sequence, and stirred at 50°C for 30 minutes to prepare four kinds of chlorine dioxide corrosion inhibitors HJ01, HJ02, HJ03 and HJ04. Chlorine oxide corrosion inhibitors, as shown in Table 1.

[0022] Table 1: Composition of different chlorine dioxide corrosion inhibitors

[0023]

[0024] In this example, amino methylene phosphate (salt) HJ01 uses ethylenediamine methylene phosphonate, HJ02 uses diethylene triamine methylene phosphonate, HJ03 uses hexamethylene diamine methylene phosphonate, HJ04 uses double 1, 6-hexamethylene triamine methylene phosphonic acid, non-ionic surfactants HJ01 and HJ02 use OP-10, HJ03 and HJ04 use AEO-9, and hydrocarbon imidazoline use 1-benzyl 1-aminoethyl-2-heptyl Alkyl imidazoline quaternary ammonium salt.

Embodiment 2

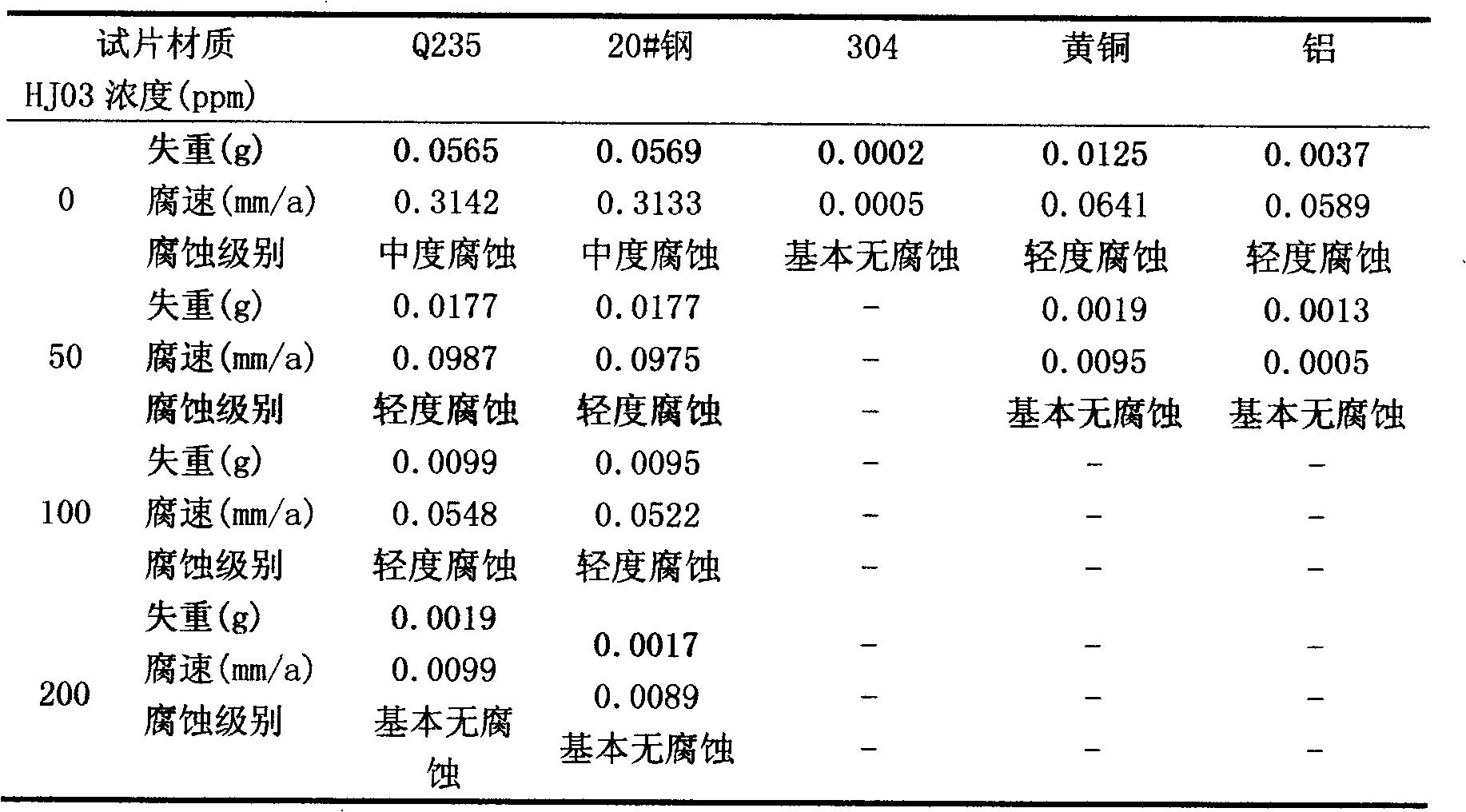

[0026] Evaluation of compound chlorine dioxide corrosion inhibitor containing aminomethylene phosphate (salt) Soak in chlorine dioxide solution for 30 minutes; for disinfection of articles contaminated by hepatitis virus and Mycobacterium tuberculosis, soak in 500 mg / L chlorine dioxide for 30 minutes; for disinfection of articles contaminated by bacterial spores, soak in 1000 mg / L chlorine dioxide for 30 minutes. The determination of the corrosivity of disinfectants to metals has specified the corrosivity level in the specification. Experimental conditions: 25°C, 72h.

[0027] According to the specification, under the condition that the concentration of chlorine dioxide is 100ppm, different concentrations of HJ03 are used to test five kinds of test pieces. The test results include weight loss (g), corrosion rate (mm / a), and corrosion level. The test results are shown in Table 2.

[0028] Table 2: Experimental results of compound chlorine dioxide corrosion inhibitor at 100ppm...

Embodiment 3

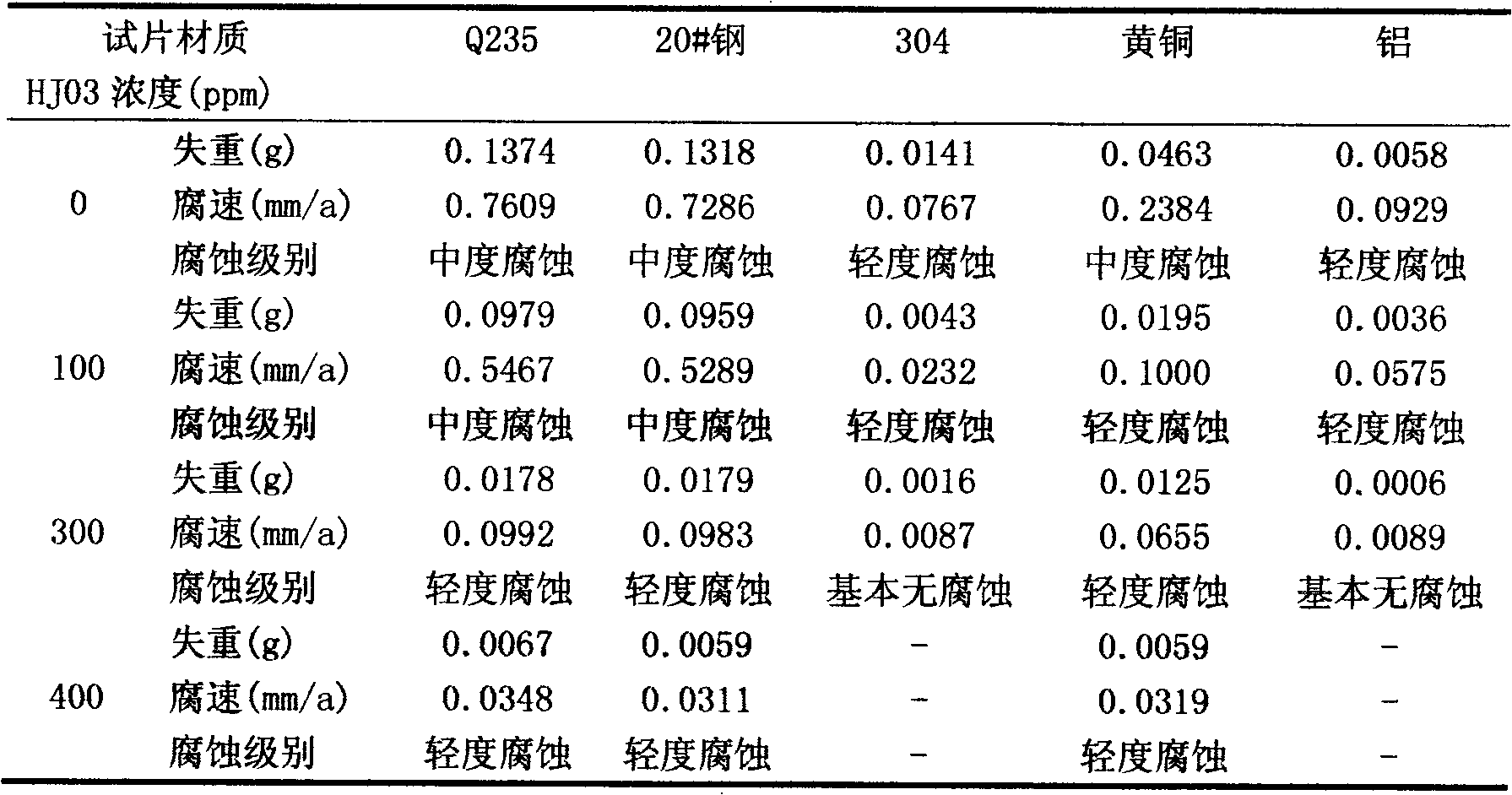

[0041] Evaluation of compound chlorine dioxide corrosion inhibitor containing aminomethylene phosphate (salt): The water samples with different concentrations of chlorine dioxide corrosion medium were selected as the test medium in the experiment. Test piece: N80 steel, temperature: 45±1°C, time: 4h, corrosion inhibitor addition amount: 100ppm. The experimental results are shown in Table 6.

[0042] Table 6: Evaluation results of laboratory corrosion inhibition performance of aminomethylene phosphate

[0043]

[0044] It can be seen from Table 6 that the chlorine dioxide corrosion inhibitor compounded with aminomethylene phosphate (salt) as the main agent, under the conditions of different concentrations of chlorine dioxide medium and the lower addition amount, has the best effect on N80 Metal materials represented by steel have high corrosion inhibition effect. The corrosion ability of the corrosion system to metal is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com