Direct methanol fuel cell catalyst and preparation method thereof

A methanol fuel cell and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve problems such as high cost, poor catalytic activity, and complicated preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing a direct methanol fuel cell catalyst, comprising the following steps: A) mixing carbon black with ammonium fluoride, heating for pyrolysis reaction, and continuing heating for fluorine doping reaction to obtain fluorine doping reaction carbon black material, the mass ratio of carbon black to ammonium fluoride is 2.5~500:1, preferably 2.5~300:1, more preferably 2.5~100:1; B) the carbon doped with fluorine The black material is mixed with melamine, heated for pyrolysis reaction, and then heated for nitrogen doping reaction to obtain a direct methanol fuel cell catalyst. The mass ratio of the fluorine-doped carbon black material to melamine is 1 to 660:1, preferably It is 1~400:1, more preferably 1~200:1.

[0045] Wherein, in step A, ammonium fluoride is used as the fluorine source, and ammonium fluoride is decomposed into ammonia gas and hydrogen fluoride under high temperature conditions, which is beneficial to t...

Embodiment 1

[0057] 1.1 Dissolve 0.14g ammonium fluoride in 30.0ml water, stir until dissolved, add 0.35g acetylene carbon black, ultrasonically disperse for 30min, stir for 24h, centrifuge at 10000rpm / min for 10min, discard the supernatant, the obtained black The precipitate was dried at 60°C. The obtained mixture was ground for 30 minutes, heated to 400° C. for 6 hours, and then heated to 800° C. for 5 hours to obtain fluorine-doped acetylene carbon black.

[0058] 1.2 Grind 0.1g of the fluorine-doped acetylene carbon black obtained in 1.1 with 0.1g of melamine for 30 minutes, heat up to 400°C for 6 hours, then continue to heat up to 800°C for 5 hours to obtain fluorine-nitrogen co-doped acetylene carbon black .

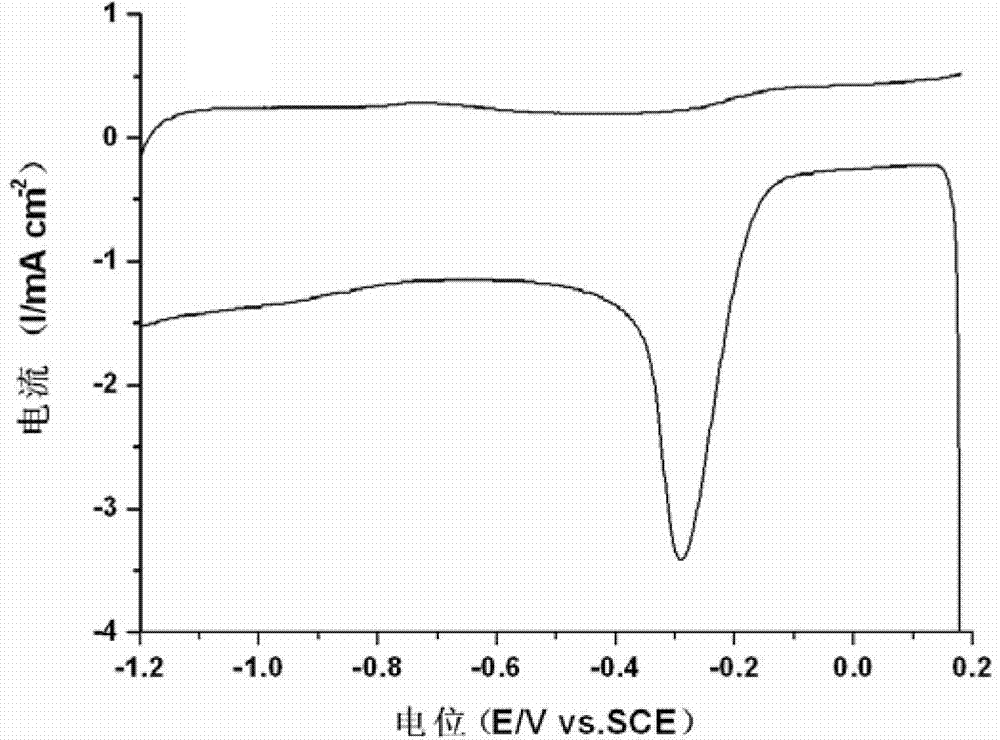

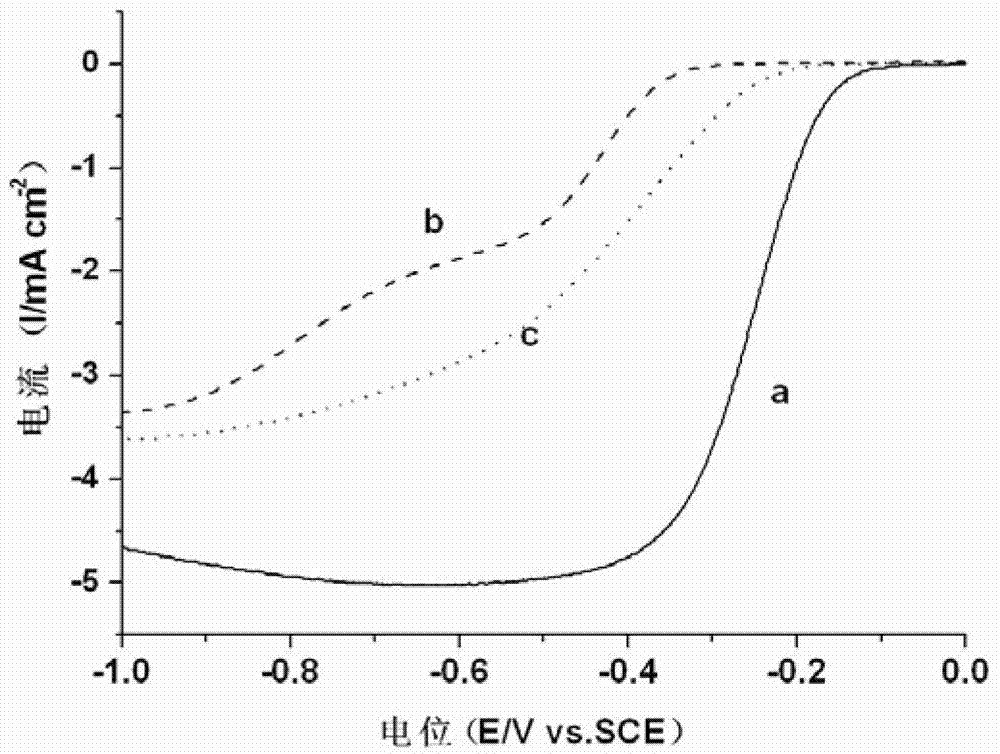

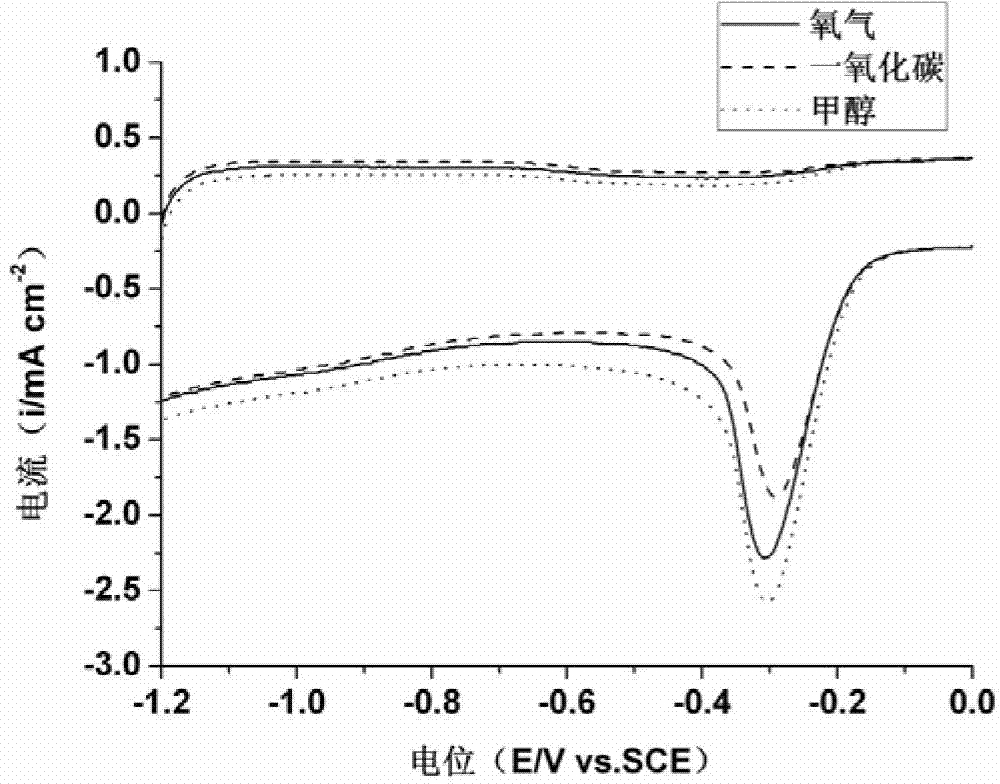

[0059] 1.3 Ultrasonic disperse 5 mg of fluorine and nitrogen co-doped acetylene carbon black obtained in 1.2 with 100 μl Nafion solution for 30 minutes to obtain a solution; take 10 μl of the solution and drop-coat it on a rotating disk electrode, and dry it at room temperatur...

Embodiment 2

[0066] 2.1 Dissolve 0.2g of ammonium fluoride in 30.0ml of water, stir until dissolved, add 0.35g of Activated carbon Vulcan XC-72 (Cabot Corporation), ultrasonically disperse for 30min, stir for 24h, then vacuum filter and dry. The obtained mixture was ground for 30 minutes, heated to 400°C for 0.5 hours in a single-temperature zone slide rail furnace, and then heated to 900°C for 1 hour to obtain fluorine-doped activated carbon Vulcan XC-72.

[0067] 2.2 Grind 0.1g of the fluorine-doped Activated carbon Vulcan XC-72 obtained in 2.1 with 0.1g of melamine for 30min, heat up to 400°C for 0.5h, then continue to heat up to 900°C for 1h to obtain fluorine-nitrogen co-doping Activated carbon Vulcan XC-72.

[0068] 2.3 Ultrasonic disperse 5 mg of fluorine nitrogen co-doped Activated carbon Vulcan XC-72 obtained in 2.2 with 100 μl Nafion solution for 30 minutes to obtain a solution; take 10 μl of the solution and drop-coat it on a rotating disk electrode, and dry it at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com