Kallidinogenase enteric coated tablet and preparation method thereof

A technology of pancreatic kininogenase and enteric-coated tablets, which is applied in the fields of pill delivery, pharmaceutical formulation, peptide/protein composition, etc., and can solve the problem of non-compliance of content uniformity of finished products, non-compliance of content uniformity and unstable drug quality and other issues to achieve the effect of avoiding titer loss, less potency unit loss, and improving content and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

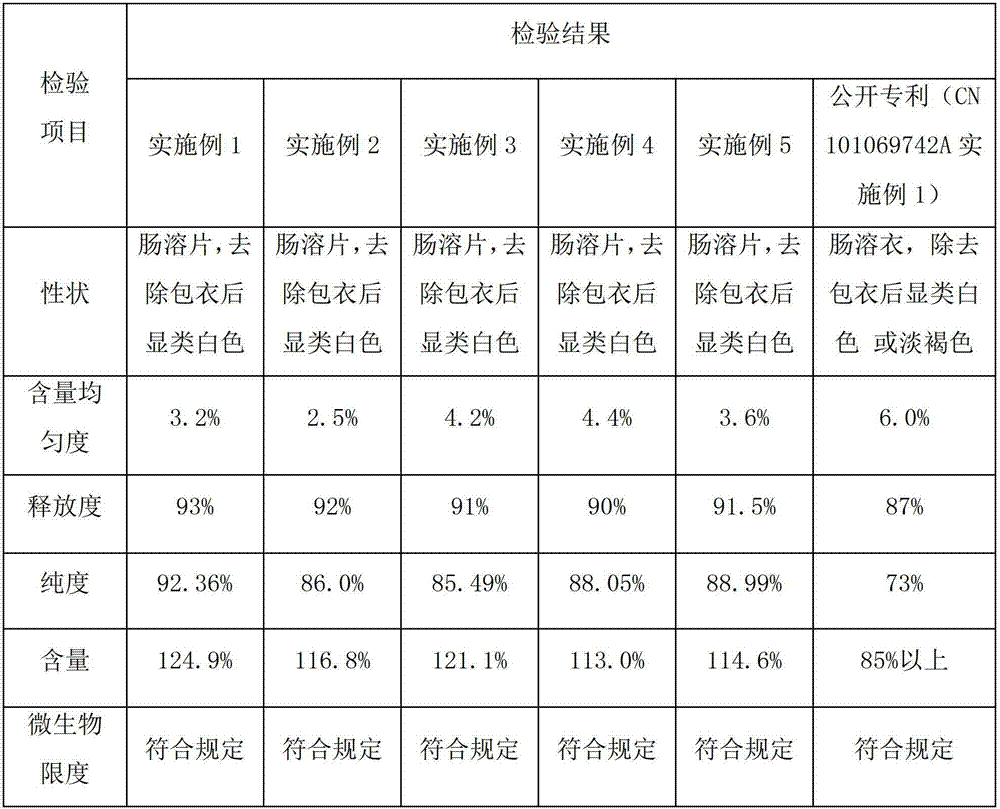

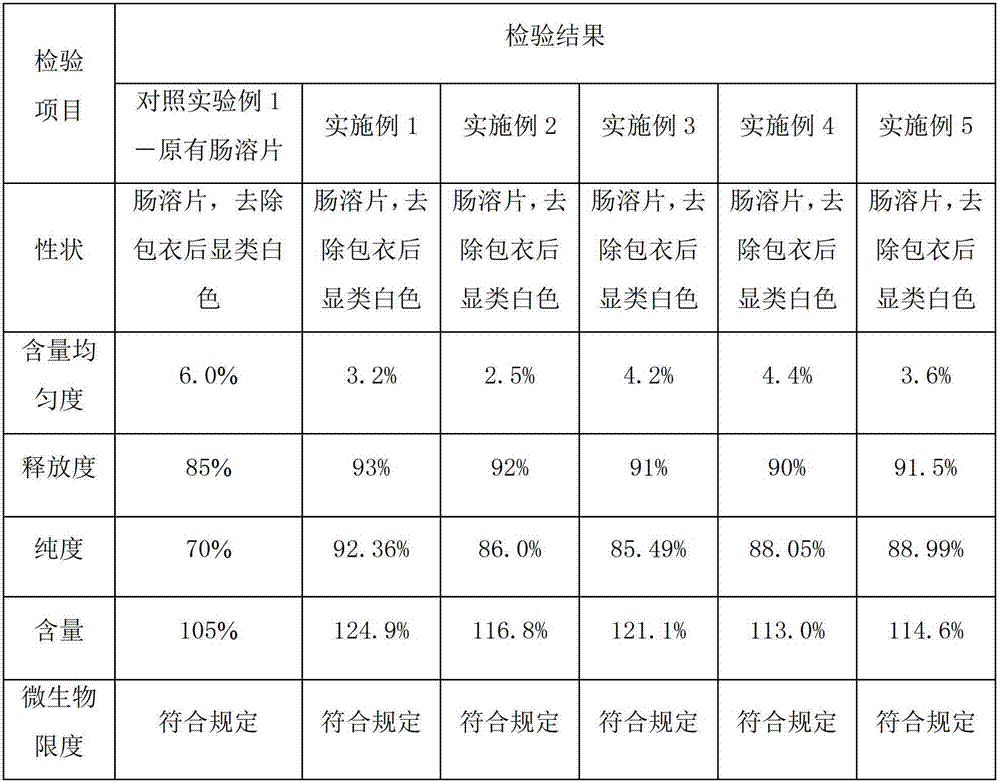

Examples

Embodiment 1

[0031] Example 1 Preparation of pancreatic kininogenase tablets

[0032] A pancreatic kininogenase enteric-coated tablet, every 1000 tablets includes the following components:

[0033] Pancreatic kininogenase: 140,000 units

[0034] Starch: 130g

[0035] Microcrystalline Cellulose: 20g

[0037] Hypromellose: 8g

[0039] Enteric Film Coating Premix (Ahua) 24g

[0040] Preparation:

[0041] 1. Preparation: Grind excipients such as pancreatic kininogenase, starch, microcrystalline cellulose, sodium carbonate, hypromellose, and magnesium stearate through an 80-mesh sieve.

[0042] 2. Prepare blank granules: Mix the weighed auxiliary materials according to the prescription amount, add purified water and stir evenly to make soft materials, pass through a 20-mesh sieve to prepare blank granules. Place the granules in a hot air circulation oven, and dry them with hot air below 50°C. The dried blank granules are size...

Embodiment 2

[0048] Example 2 Preparation of pancreatic kininogenase tablets

[0049] A pancreatic kininogenase enteric-coated tablet, every 1000 tablets includes the following components:

[0050] Pancreatic kininogenase: 90,000 units

[0051] Lactose: 140g

[0052] Microcrystalline Cellulose: 15g

[0053] Sodium Alginate 25g

[0054] Hypromellose: 6g

[0056] Enteric film coating premix (Yingmao) 28

[0057] 1. Preparation: Grind excipients such as pancreatic kininogenase, lactose, microcrystalline cellulose, sodium alginate, hypromellose, and magnesium stearate through an 80-mesh sieve.

[0058] 2. Prepare blank granules: Mix the weighed auxiliary materials according to the prescription amount, add purified water and stir evenly to make soft materials, pass through a 20-mesh sieve to prepare blank granules. Place the granules in a hot air circulation oven, and dry them with hot air below 50°C. The dried blank granules are sized with a 20-mesh stainles...

Embodiment 3

[0063] Example 3 Preparation of pancreatic kininogenase tablets

[0064] A pancreatic kininogenase enteric-coated tablet, every 1000 tablets includes the following components:

[0065] Pancreatic kininogenase: 120,000 units

[0066] Lactose: 120g

[0067] Sodium starch glycolate: 18g

[0069] Hypromellose: 7g

[0071] Enteric Film Coating Premix (Ahua) 20g

[0072] 1. Preparation: Grind excipients such as pancreatic kininogenase, lactose, sodium starch glycolate, calcium chloride, hypromellose, and magnesium stearate through an 80-mesh sieve.

[0073] 2. Prepare blank granules: Mix the weighed auxiliary materials according to the prescription amount, add purified water and stir evenly to make soft materials, pass through a 20-mesh sieve to prepare blank granules. Place the granules in a hot air circulation oven, and dry them with hot air below 50°C. The dried blank granules are sized with a 20-mesh stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com