Detection method of determining 16 types of photoinitiators in paper printing and packaging material

A photoinitiator, printing and packaging technology, applied in] The present invention belongs to the technical field of physical and chemical inspection of paper printing and packaging materials, can solve the problems of affecting cell membrane movement, health hazards, contaminated food, etc., and achieves low cost, low consumption, Effects with high sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

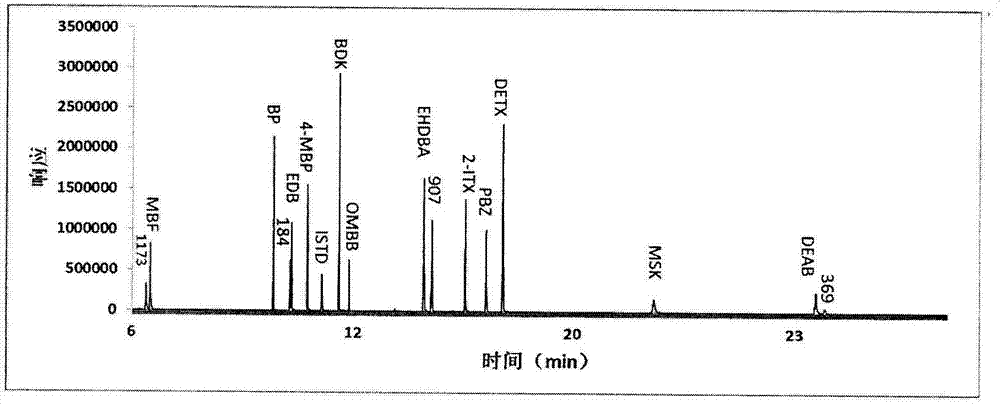

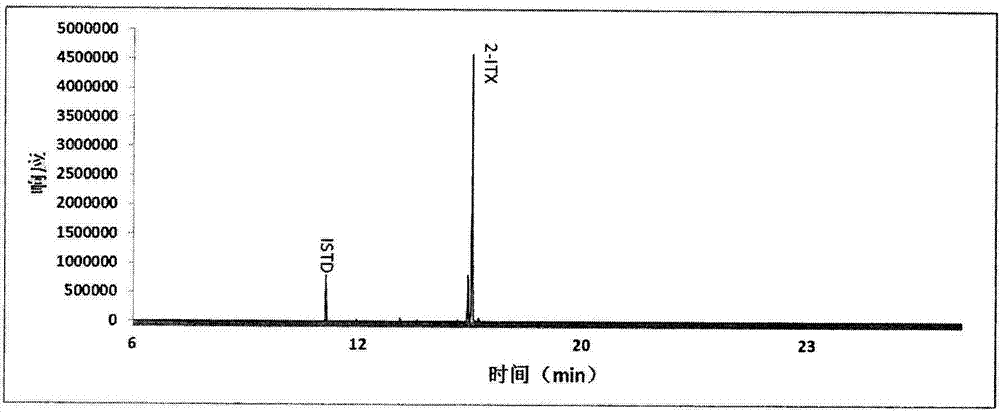

[0048] In this embodiment, the detection method for the content of 16 kinds of photoinitiators in the paper packaging material is as follows.

[0049] 1. Reagents and materials

[0050] Unless otherwise specified, reagents of analytical grade or above should be used. Including water; n-hexane; ethanol; p-hydroxyanisole (polymerization inhibitor): purity ≥ 98%; photoinitiator: purity ≥ 97%, see Table 1; deuterated anthracene (internal standard): purity ≥ 98%.

[0051] 2. Solution configuration

[0052] Extractant: Prepare a mixed solution of n-hexane and ethanol with a concentration of p-hydroxyanisole of 500 mg / L (1:1, V / V)

[0053] Internal standard stock solution: use the extractant to prepare a deuterated anthracene internal standard solution with a concentration of 1000 mg / L. Sealed and protected from light and stored at 0 ℃ ~ 4 ℃.

[0054] Preparation of standard solution

[0055] Weigh 25 mg of photoinitiator to the accuracy of 0.1 mg, dissolve it with extractant an...

example 2

[0072] In order to ensure the stability of photoinitiators in the analysis process, the method of the present invention investigates the influence of visible light and p-hydroxyanisole (HQMME) inhibitors on the stability of 16 photoinitiators.

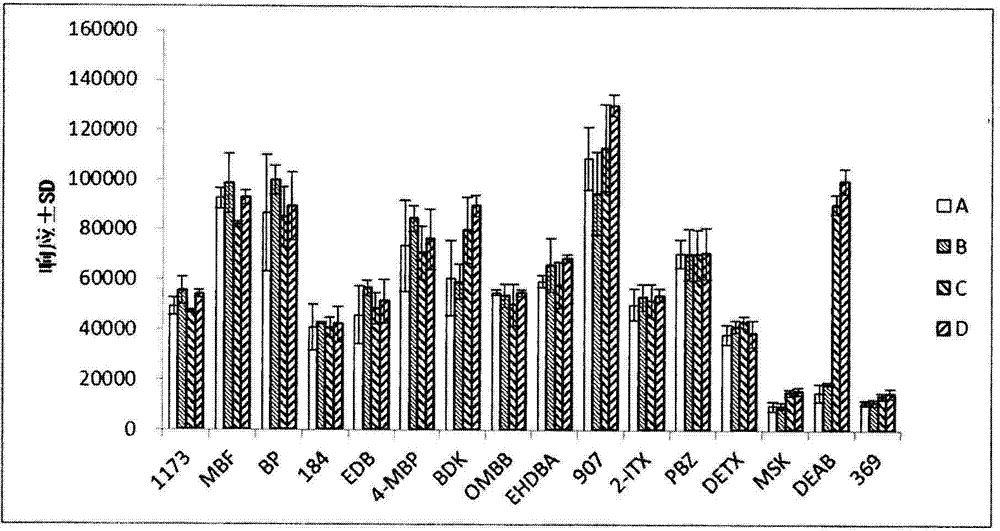

[0073] The present invention configures n-hexane / ethanol (1:1, V:V) solutions of photoinitiators of the same concentration in four groups of 10 mL volumetric flasks, which are respectively recorded as A, B, C, and D (A: common volumetric flask No polymerization inhibitor added; B: ordinary volumetric flask with polymerization inhibitor added; C: brown volumetric flask without polymerization inhibitor; D: brown volumetric flask with polymerization inhibitor added), each group of samples was made in 3 parallels, and the added polymerization inhibitor The concentration is 500 mg / L. Then place the sample on the window sill of a laboratory exposed to sunlight, and detect it after 3 days, and the results are as follows: image 3 shown. It ...

example 3

[0077]The study found that although the n-hexane / ethanol (1:1, V / V) system can extract the photoinitiator in the sample well, it will also extract a large amount of ink macromolecular pigments at the same time. The resistance of membrane filtration is very high, and the impurity removal effect is not good. At present, the commonly used sample impurity removal techniques mainly include solid-phase extraction, liquid-liquid extraction, and dilution. After experiments, it was found that solid-phase extraction still has the characteristics of high resistance and poor impurity removal effect, while the dilution and impurity removal method will greatly reduce the sensitivity of the detection method. Therefore the present invention investigates the effectiveness of the liquid-liquid extraction impurity removal method.

[0078] In the present invention, 5 mL of positive sample extract and standard working solution and 10 mL of stoppered graduated test tube were respectively added to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com