Method for preparing high-purity quaternary ammonium hydroxide by electrolyzing organic ammonium salt with perfluorinated ion exchange membrane in chlor-alkali

A perfluorinated ion, quaternary ammonium base technology, applied in electrolytic organic production, electrolytic process, organic diaphragm, etc., can solve the problem of resistance to nascent chlorine atom oxidation, poor resistance to electrolysis environment and strong alkali resistance, unable to meet production needs and other problems, to achieve the effect of strong electrochemical corrosion resistance, simple method and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

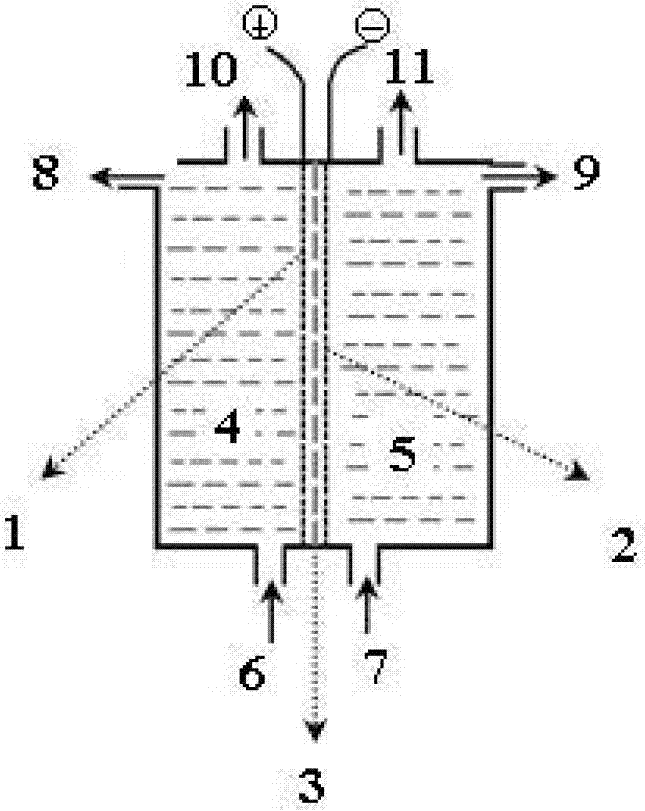

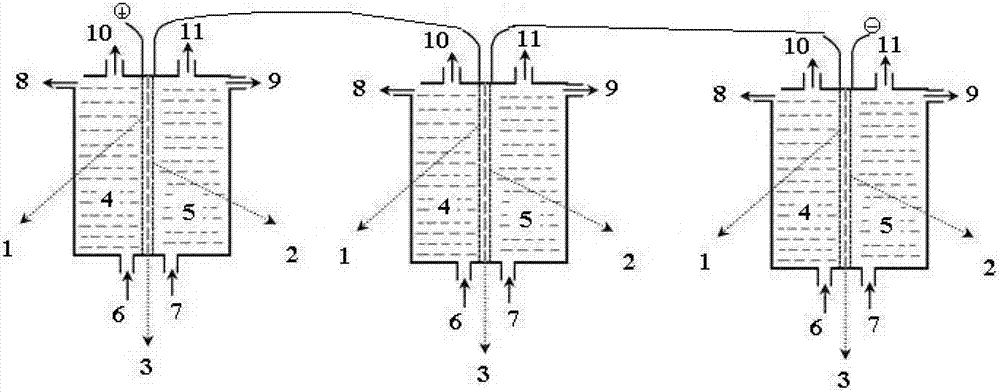

[0053] A method for preparing quaternary ammonium base by electrolysis, by using an electrolytic cell with a perfluorinated ion-exchange membrane 3 arranged between electrodes and mainly composed of an anode chamber 4, an anode 1, a perfluorinated ion-exchange membrane 3, a cathode 2, and a cathode chamber 5, Follow these steps:

[0054] (1) in such as figure 1 Electrochemical ion exchange is carried out in the ion-exchange membrane electrolyzer shown, the cathode 2 electrode is a nickel-based mesh electrode, the anode 2 electrode is a titanium-based mesh electrode, and the perfluorinated ion exchange membrane 3 is DF988 perfluorocarboxylic acid for chlor-alkali — Perfluorosulfonic acid composite membrane ion membrane;

[0055] The anolyte is an aqueous solution of tetramethylammonium chloride, and the catholyte is a tetramethylammonium hydroxide (TMAH) solution; pump the anolyte and catholyte into the anode chamber and the cathode chamber of the electrolytic cell respectivel...

Embodiment 2

[0059] (1) in such as figure 1 Electrochemical ion exchange is carried out in the ionic membrane electrolyzer shown, the cathode electrode is a stainless steel-based mesh electrode (with active coating), the anode electrode is a titanium-based mesh electrode, and the ion membrane is DF988 perfluorocarboxylic acid for chlor-alkali — Perfluorosulfonic acid composite ion membrane;

[0060] The anolyte is an aqueous solution of trimethylbenzyl ammonium chloride, and the catholyte is an aqueous solution of trimethylbenzyl ammonium hydroxide; pump the anolyte and catholyte into the anode chamber and cathode chamber of the electrolytic cell for circulation;

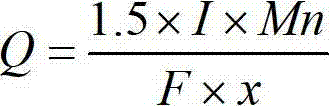

[0061] (2) At 55°C, apply direct current to the electrolytic cell for constant current electrolysis, with a current density of 3kA / m 2 , the concentration of the anolyte entering the tank is controlled at a mass concentration of about 30%; the mass concentration of the catholyte entering the tank is 29%, and the mass concentrat...

Embodiment 3

[0064] Same as Example 1, the difference is that the ionic membrane used in step (1) is F8020 type chlor-alkali ionic membrane. The calculation shows that the cathodic current efficiency of this process is 97.31%, and the purity of the quaternary ammonium base tetramethylammonium hydroxide is more than 99.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com