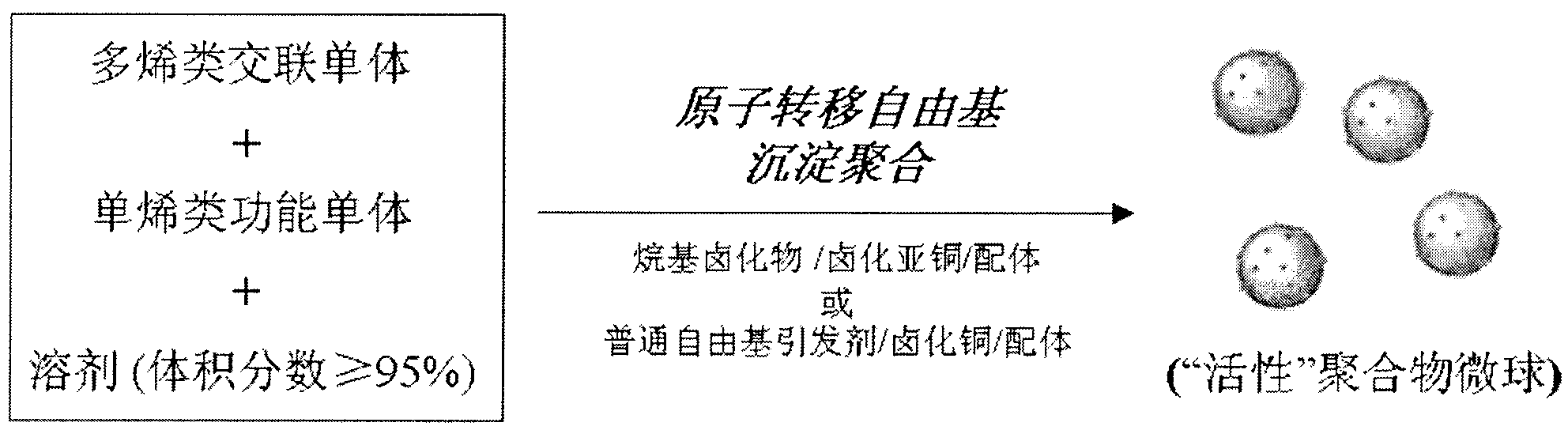

Method for preparing monodispersed polymer microsphere resin by atom transfer radical precipitation polymerization

An atom transfer and monodisperse technology, which is applied in the field of monodisperse nano/micro polymer microspheres and their preparation, can solve problems such as uncontrollable and controllable limitations of the surface grafting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

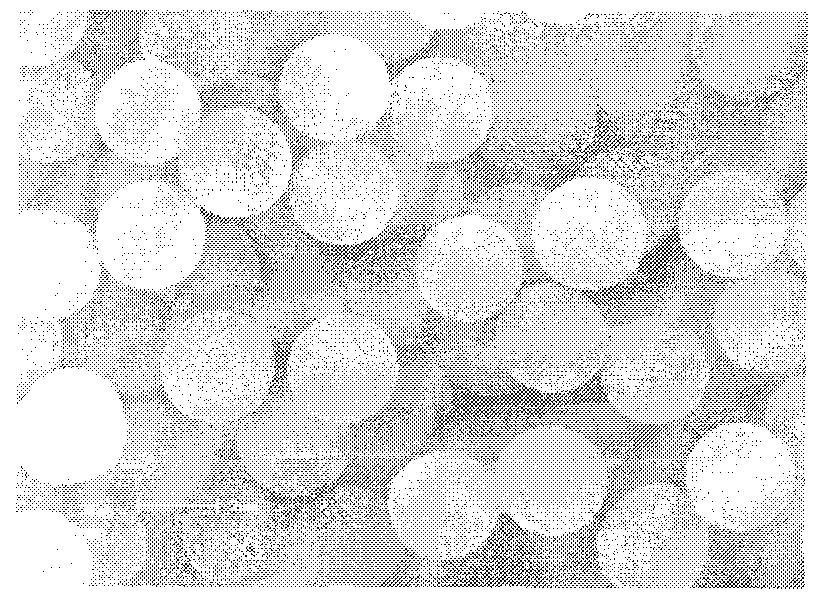

[0030] Example 1: Add functional monomer 4-vinylpyridine (4-VP, 0.031 mL), crosslinker EGDMA (0.22 mL) and anhydrous acetonitrile (30 mL) into a round bottom flask (50 mL). The reaction solution was passed through argon to remove oxygen for 15 minutes, then CuCl (1.3 mg) and the catalyst ligand PMDETA (0.0055 mL) were added, and the initiator 2-chloropropionate ethyl ester (0.0016 mL) was added after continuing to pass argon for 15 minutes, and the reaction bottle was After sealing, it was placed in an oil bath at 60° C. for 24 hours of reaction. After the reaction, the product was washed with methanol several times, and then vacuum-dried at 40° C. to constant weight (yield 46%).

[0031] The scanning electron micrographs of the obtained polymer microspheres are shown in figure 2 (number average diameter D n =2.83 μm, particle size polydispersity index U=1.004).

example 2

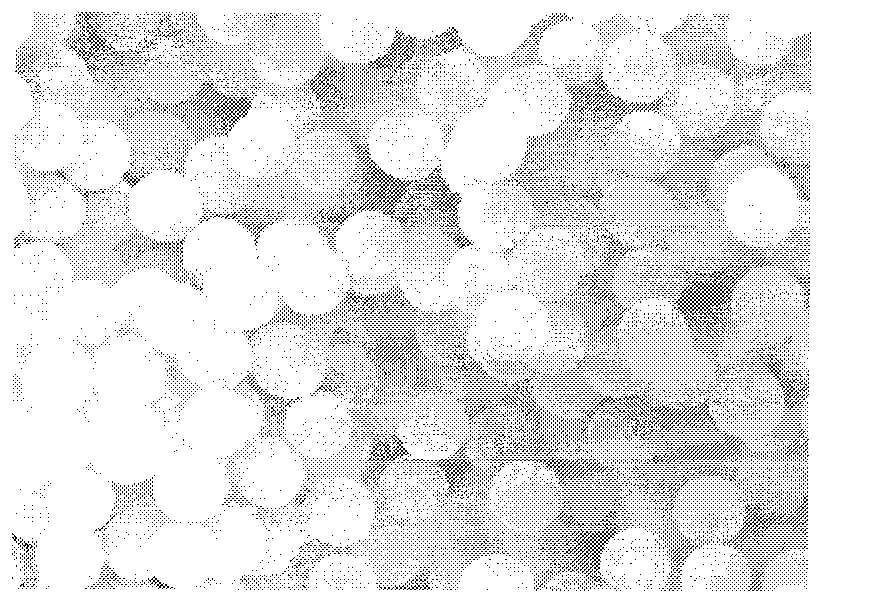

[0032] Example 2: Add functional monomer 4-VP (0.054 mL), crosslinker EGDMA (0.38 mL) and anhydrous acetonitrile (30 mL) into a round bottom flask (50 mL). The reaction solution was passed through argon to remove oxygen for 15 minutes, then CuCl (2.24 mg) and the catalyst ligand PMDETA (0.0094 mL) were added, and the initiator 2-chloropropionate ethyl ester (0.0029 mL) was added after continuing to flow argon for 15 minutes, and the reaction bottle was After sealing, it was placed in an oil bath at 60° C. for 7 hours of reaction. After the reaction, the product was washed with methanol several times, and then vacuum-dried at 40° C. to constant weight (yield 26%).

[0033] The scanning electron micrographs of the obtained polymer microspheres are shown in image 3 (D n = 1.86 μm, U = 1.007).

example 3

[0034] Example 3: Add functional monomer 4-VP (0.062 mL), crosslinker EGDMA (0.22 mL) and anhydrous acetonitrile (30 mL) into a round bottom flask (50 mL). The reaction solution was passed through argon gas for deoxygenation for 15 min, then CuCl (1.44 mg) and catalyst ligand PMDETA (0.0061 mL) were added, and the initiator 2-chloropropionate ethyl ester (0.00175 mL) was added after continuing to pass argon gas for 15 min, and the reaction bottle was After sealing, it was placed in an oil bath at 60° C. for 24 hours of reaction. After the reaction, the product was washed with methanol several times, and then vacuum-dried at 40° C. to constant weight (yield 35%).

[0035] The scanning electron micrographs of the obtained polymer microspheres are shown in Figure 4 (D n =2.96 μm, U=1.012).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com