Catalyst for preparation of ethanol through acetic acid hydrogenation and preparation method thereof

A catalyst, a technology for producing ethanol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as reducing the yield of ethanol, and achieve the effects of promoting dispersion, reducing dosage, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

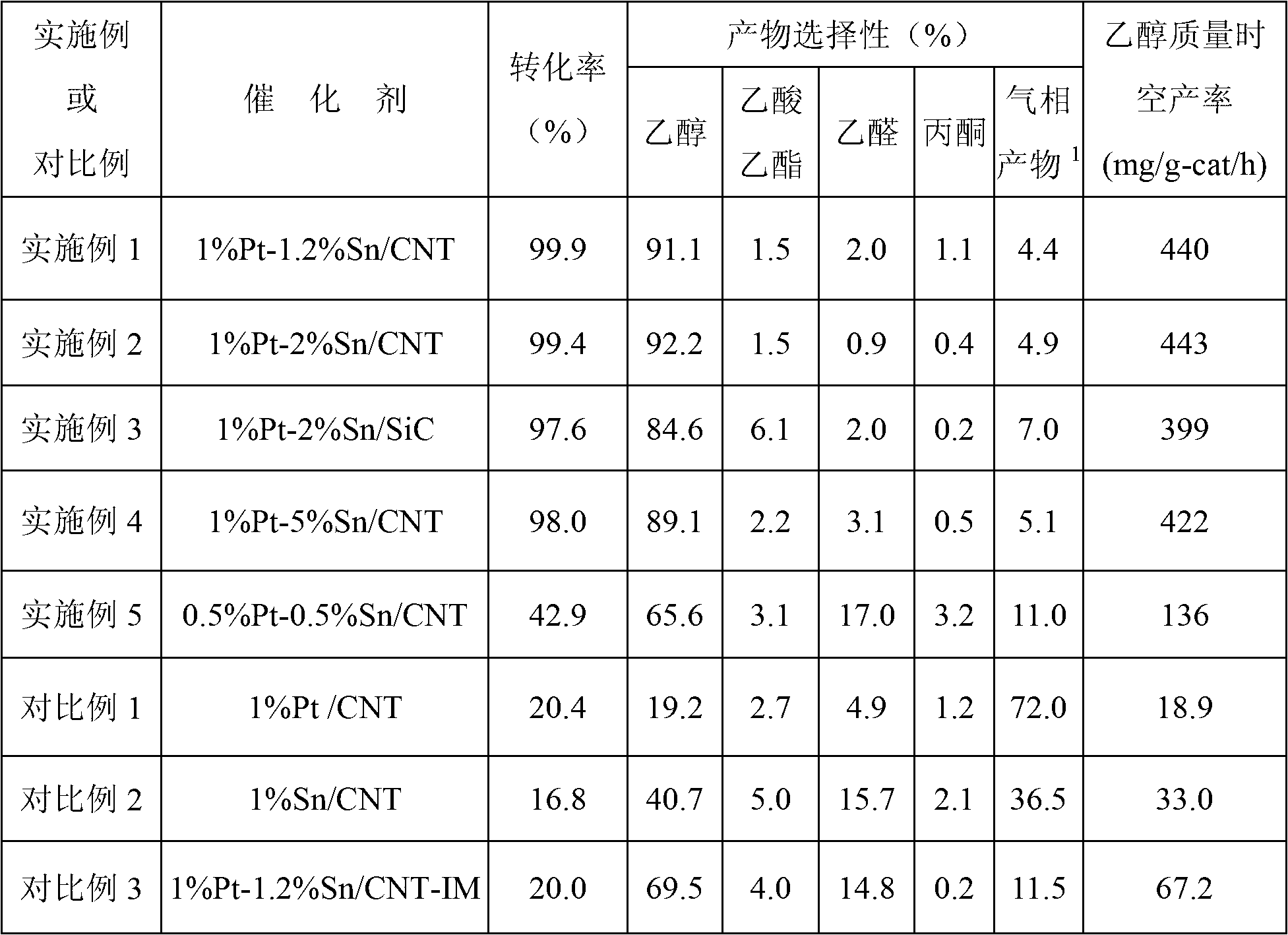

Embodiment 1

[0026] 1%Pt-1.2%Sn / CNT catalyst:

[0027] 1) The purchased CNT crude product (diameter 10-60nm, length 1-15μm, specific surface area 40-300m 2 / g) 5.0g was refluxed with 100mL of concentrated nitric acid in an oil bath at 80°C for 10h, filtered, washed and dried. Weigh 1.0 g of the treated CNT, add it into 100 mL of ethylene glycol solution, and disperse it by ultrasonic for 1 h.

[0028] 2) Measure 6.6 mL of 1.5 mg / mL chloroplatinic acid-ethylene glycol solution and 1.5 mL of 8 mg / mL stannous chloride-ethylene glycol solution, and mix them uniformly to obtain solution A.

[0029] 3) Prepare 250 mL of 0.6 mg / mL sodium dodecyl sulfate (SDS)-ethylene glycol solution.

[0030] 4) Mix solution A and the SDS-ethylene glycol solution prepared in step 3) and the ultrasonically dispersed CNTs in step 1) at room temperature for 1 hour, then slowly add 0.5mol / L NaBH dropwise under continuous stirring 4 -EG solution 10mL, then stirred for 5h, vacuum filtered, washed with deionized water...

Embodiment 2

[0034] 1%Pt-2%Sn / CNT catalyst:

[0035] The preparation method of CNT-loaded Pt-Sn bimetallic catalyst is the same as embodiment 1, but the tin protochloride-ethylene glycol solution of 8mg / mL is 2.5mL, other composition is constant, makes 1%Pt-2%Sn / CNT catalyst, the performance evaluation and product analysis conditions of catalyst to the ethanol hydrogenation of acetic acid are the same as embodiment 1, and the results are shown in Table 1.

Embodiment 3

[0037] 1%Pt-2%Sn / SiC catalyst:

[0038] The preparation method of the silicon carbide-supported Pt-Sn bimetallic catalyst is the same as in Example 1, except that the carbon nanotubes are replaced by silicon carbide carriers, and the silicon carbide is not pre-treated. A 1%Pt-2%Sn / SiC catalyst was prepared. The performance evaluation and product analysis conditions of the catalyst for the hydrogenation of acetic acid to ethanol were the same as in Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com