Method and apparatus for continuous oil product hydrodesulphurization by using microwaves

A hydrodesulfurization and microwave technology, applied in the chemical/physical/physicochemical process of energy application, refining to remove heteroatoms, etc., can solve the problems of low desulfurization rate, easy to block pipelines, cumbersome operation, etc., to improve oil quality Effect of desulfurization rate and economic improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

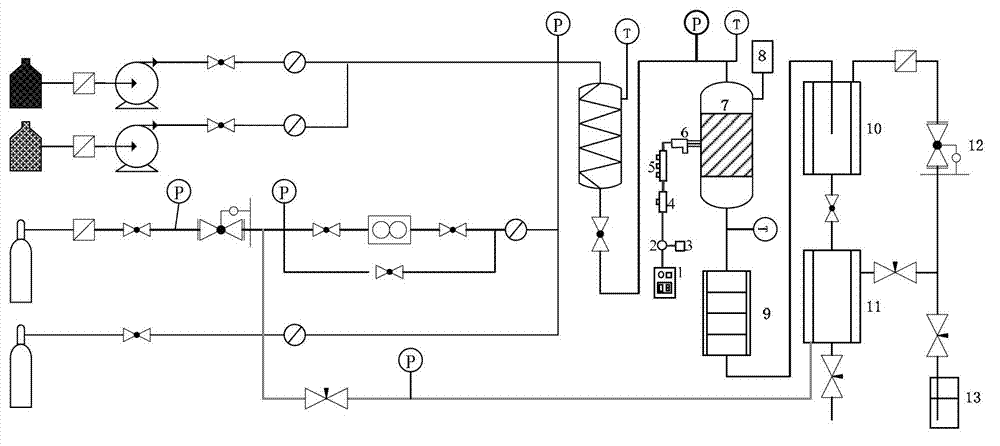

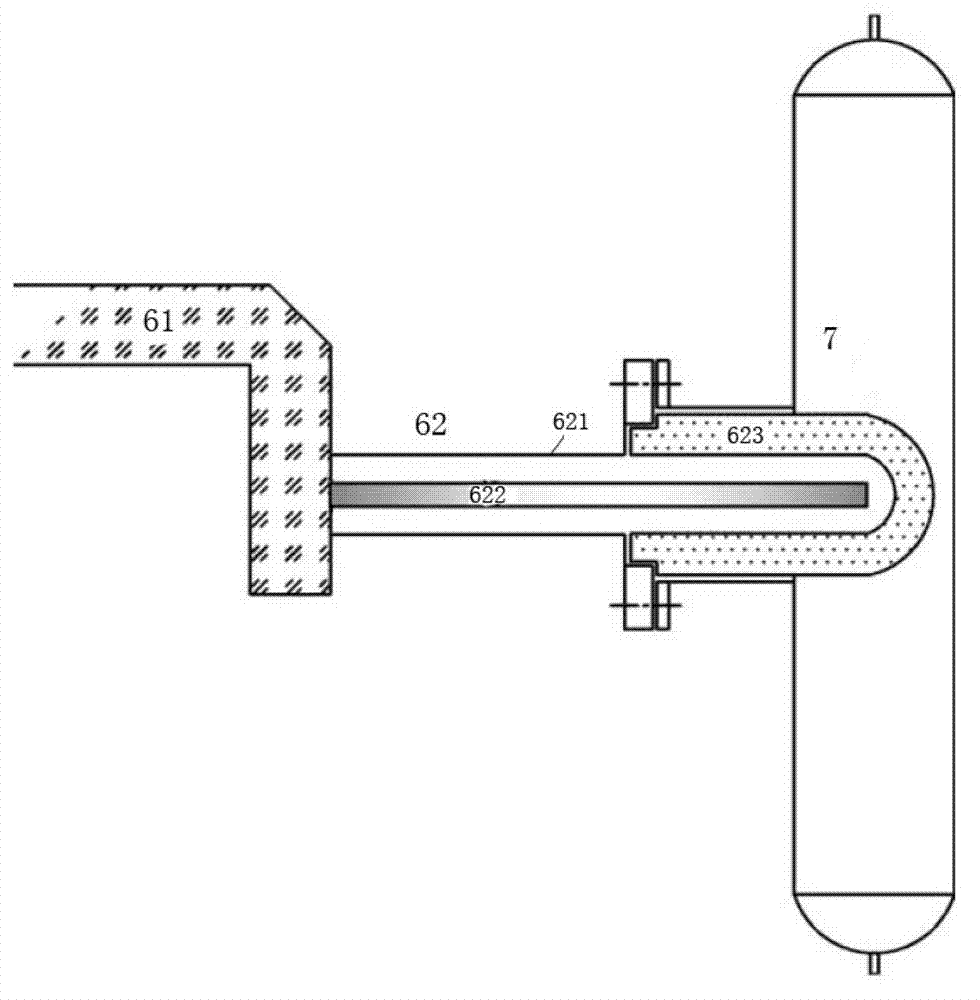

Method used

Image

Examples

Embodiment 1

[0047] Choose Co-Mo / γ-Al 2 o 3 Catalyst and FCC gasoline from a refinery, the total sulfur content is 340ppm, and the sulfide types are mainly: thiophene, C1 thiophene, C2 thiophene, and C3 thiophene. At heavy hourly space velocity 2h -1 , reaction pressure 2MPa, reaction temperature 250°C, hydrogen-oil ratio 200:1. The conditions of HDS with microwave action (1.2kW) and without microwave action were investigated respectively. It was found that the desulfurization rate was 78.2% with microwave and 52.6% without microwave. It can be seen that under the same operating conditions, the presence of microwave field can significantly improve the hydrodesulfurization rate of FCC gasoline. Further research on the hydrodesulfurization of FCC gasoline shows that the degree of olefin hydrogenation is low in the presence of microwaves, which is the effect of selective heating by microwaves. decreased, but increased by one unit (the octane value of the hydrodesulfurization process witho...

Embodiment 2

[0049] Select microwave high temperature and high pressure reactor and Ni-Mo / γ-Al 2 o 3 Catalyst, catalyst loading is 25mL catalyzer, and wherein catalyst grain number is 60~80 orders, prepares gasoline model compound, the thiophene of 200ppm is matched in 70% n-heptane, 20% hexanaphthene, 5% toluene and 5% benzene In ethylene, the model compound was subjected to hydrodesulfurization reaction, the specific operating conditions: catalyst loading 20ml, reaction temperature 280°C, reaction pressure 2MPa, weight hourly space velocity (WHSV) 2.5h -1 , Hydrogen oil volume ratio 150:1, microwave power 2kW. After the microwave reaction, the sulfur content of the gasoline model product is less than 5ppm, the hydrodesulfurization rate is 98%, and the liquid yield is more than 98%.

Embodiment 3

[0051] Ni-Mo / γ-Al is selected in this reaction system 2 o 3 The catalyst is tested on FCC gasoline with a sulfur content of 450ppm. The reaction conditions are: reaction temperature 240 degrees, pressure 2.5MPa, space velocity 2h -1 , Hydrogen oil ratio 200:1, microwave power 2.0KW, the sulfide removal rate in FCC is 98%.

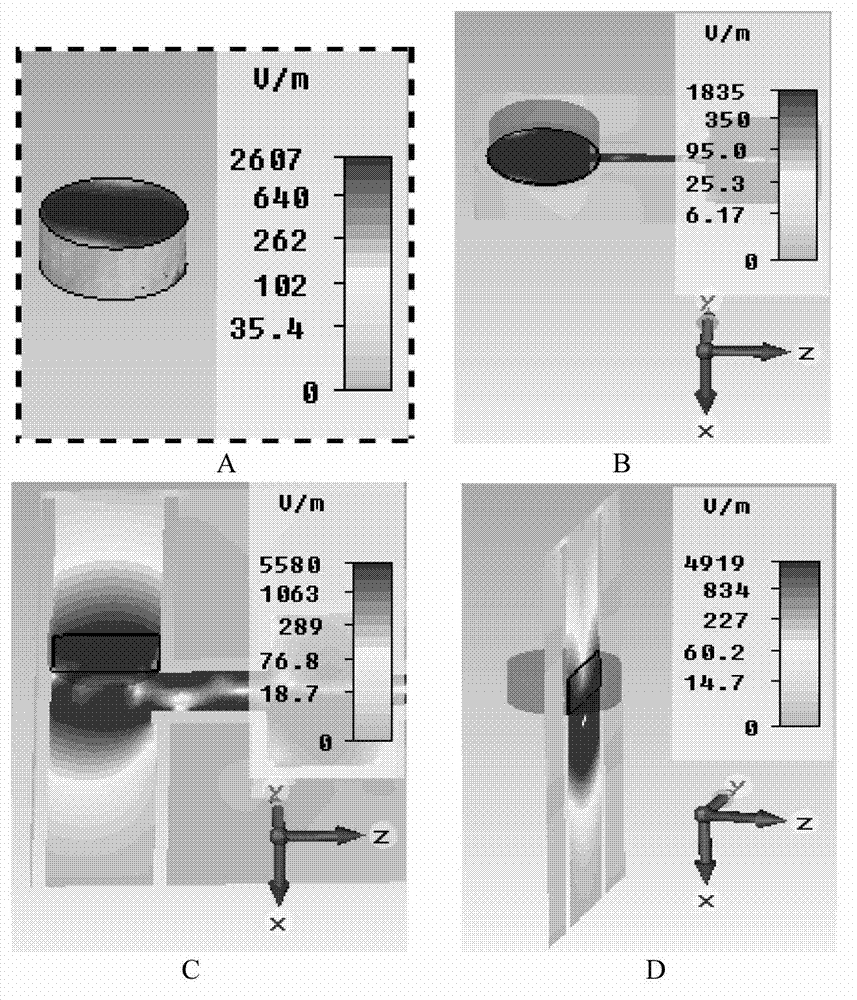

[0052] image 3 Co-Mo / γ-Al is shown 2 o 3 The electric field distribution diagram of the catalyst bed in the device when the catalyst is used (the electric field distribution forms of the three embodiments are basically the same). Picture A is the overall picture, and pictures B, C, and D are cross-sectional views in the X, Y, and Z directions, respectively. It can also be seen from the figure that the microwave distribution is uniform, and there is no microwave leakage, and the operation is safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com