Hydrofining method of low-grade gasoline/diesel oil

A hydrogenation refining, gasoline and diesel technology, applied in the direction of refined hydrocarbon oil, petroleum industry, etc., can solve the problems of low yield of diesel oil, reduce aromatics content, etc., achieve denitrogenated olefin content, reduce olefin content, and increase specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

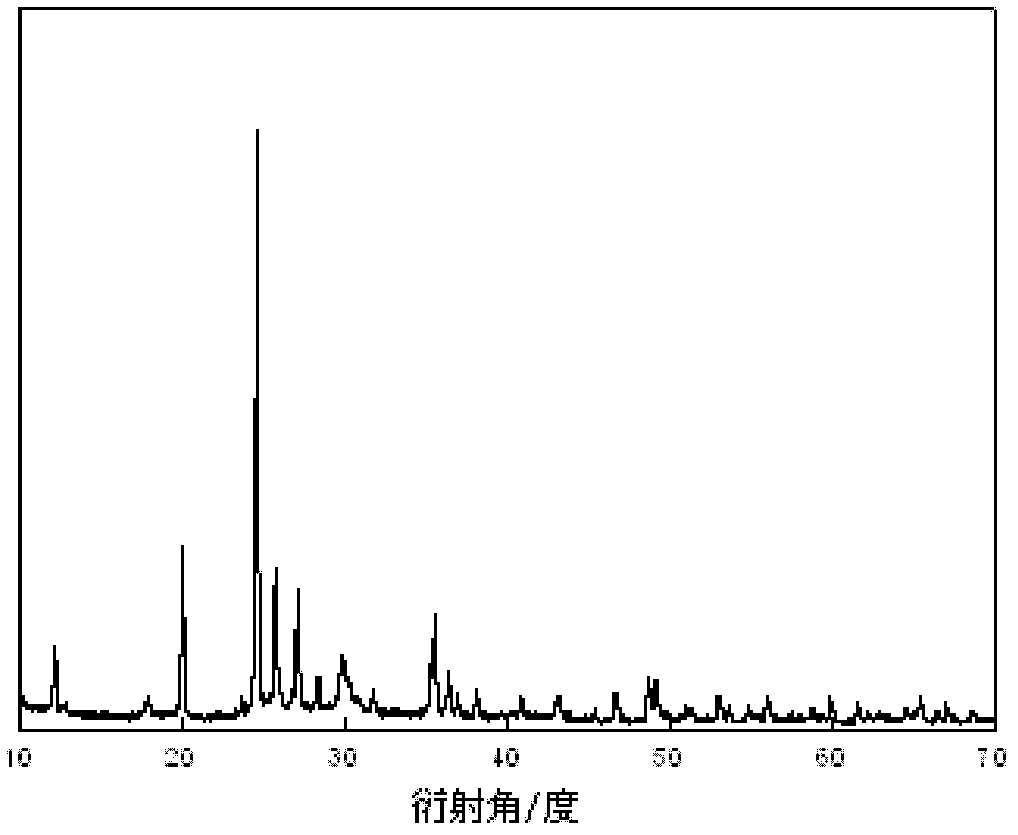

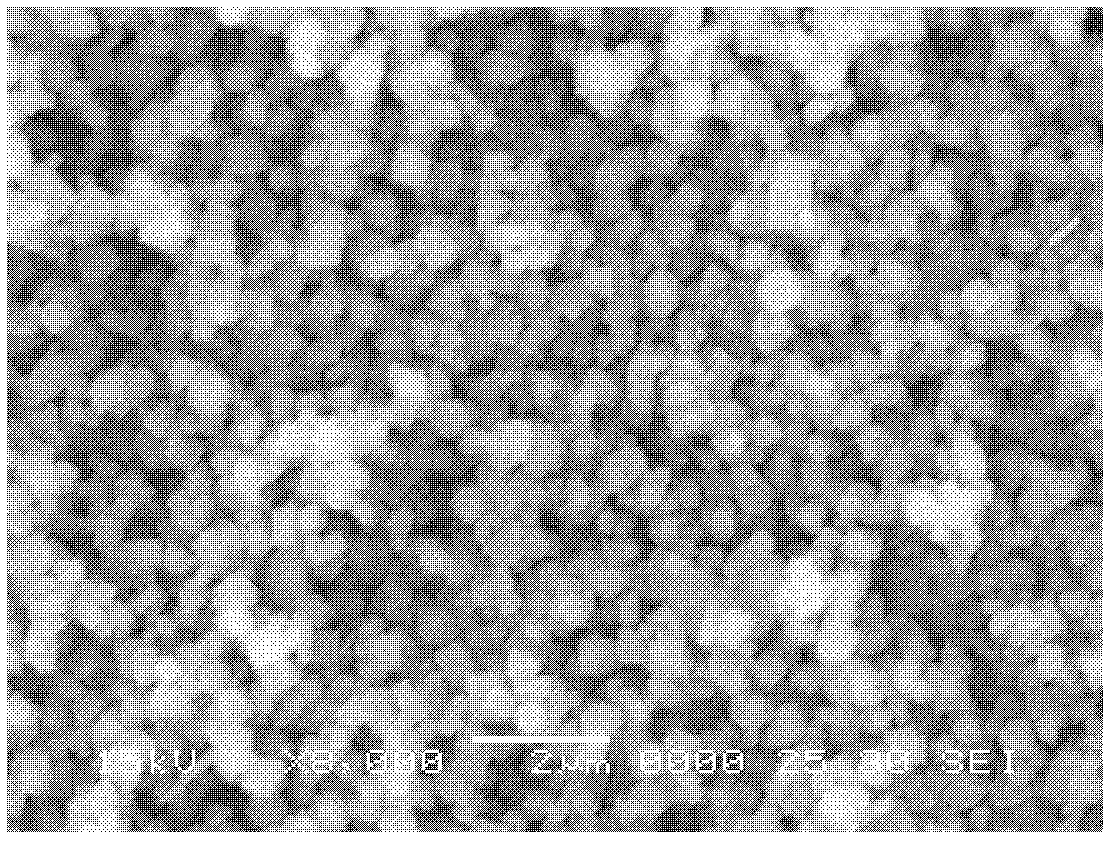

[0017] Catalyst of the present invention, used titanium silicon molecular sieve properties are as follows: TiO 2 / SiO 2 Molar ratio is 0.1~0.5, preferably 0.15~0.45, Na 2 O and K 2 The total weight content of O is less than 0.2wt.%, preferably less than 0.15wt.%, and the molecular sieve grain size is not greater than 2 μm.

[0018] Small-grain titanium-silicon molecular sieves are sodium and potassium-type, or ammonium ion-exchanged, roasted to hydrogen-type, or small-grain titanium-silicon modified by introducing other metal ions by impregnation, co-precipitation or ion exchange. Molecular sieves, or in-situ synthesized heteroatom small-grain titanium-silicon molecular sieves containing different metal ions.

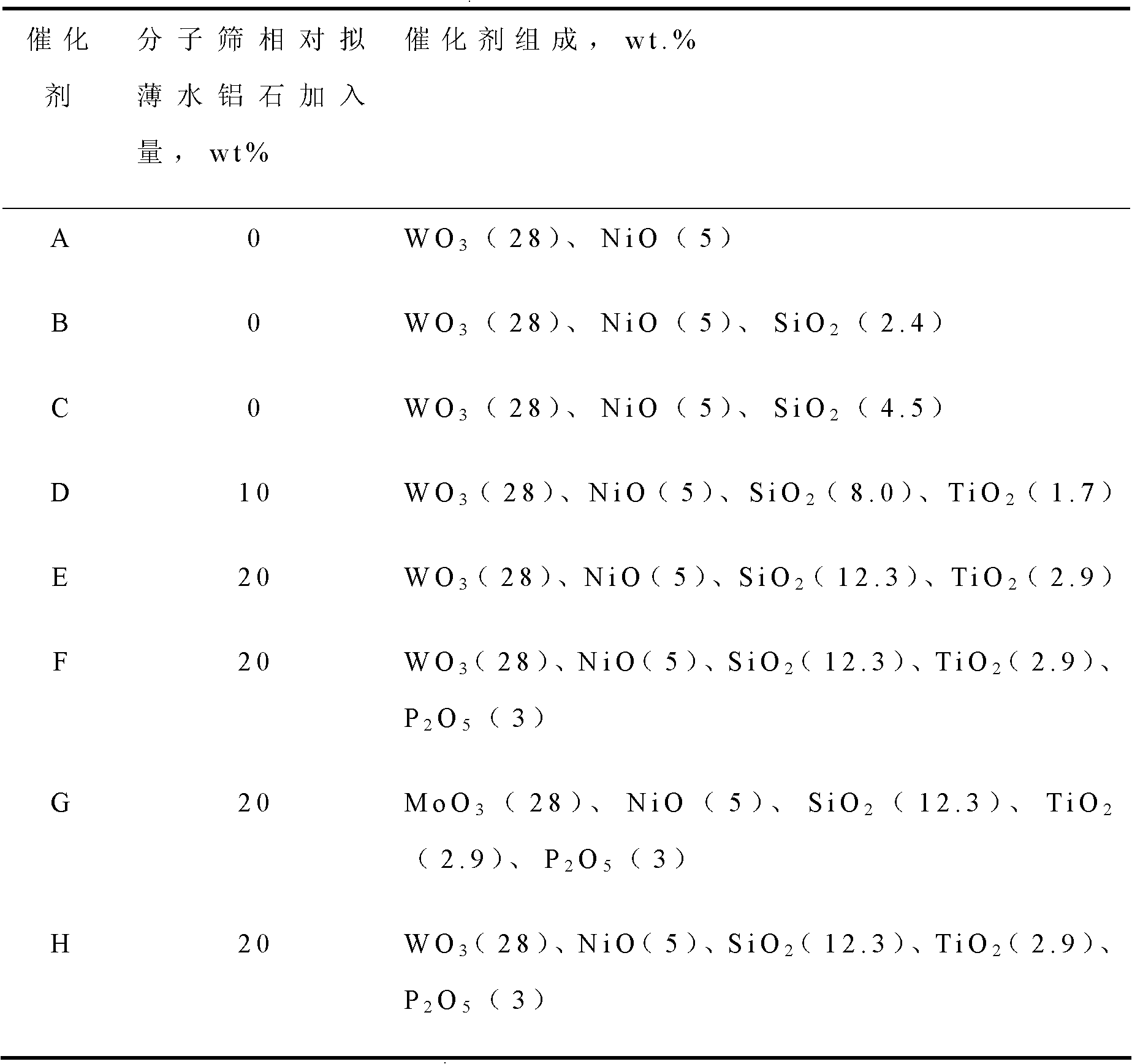

[0019] The alumina used in the present invention is industrial pseudo-boehmite, or an industrial alumina carrier with pore distribution. Introduce element Si to modify it by kneading or co-precipitation; refractory inorganic oxide can be used as the binder component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com