Polyaniline/ titanium dioxide nanometer composite impedance type thin film gas sensor and preparation method thereof

A gas sensor and titanium dioxide technology, applied in the field of sensors, can solve the problems of inappropriate control of the contact between the sensitive film and the sensor substrate, the inability to reuse conductive polymer residues, and the thickness of the sensitive film of the gas sensor, so as to facilitate the response sensitivity and promote the charge Migration, effects on response sensitivity and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

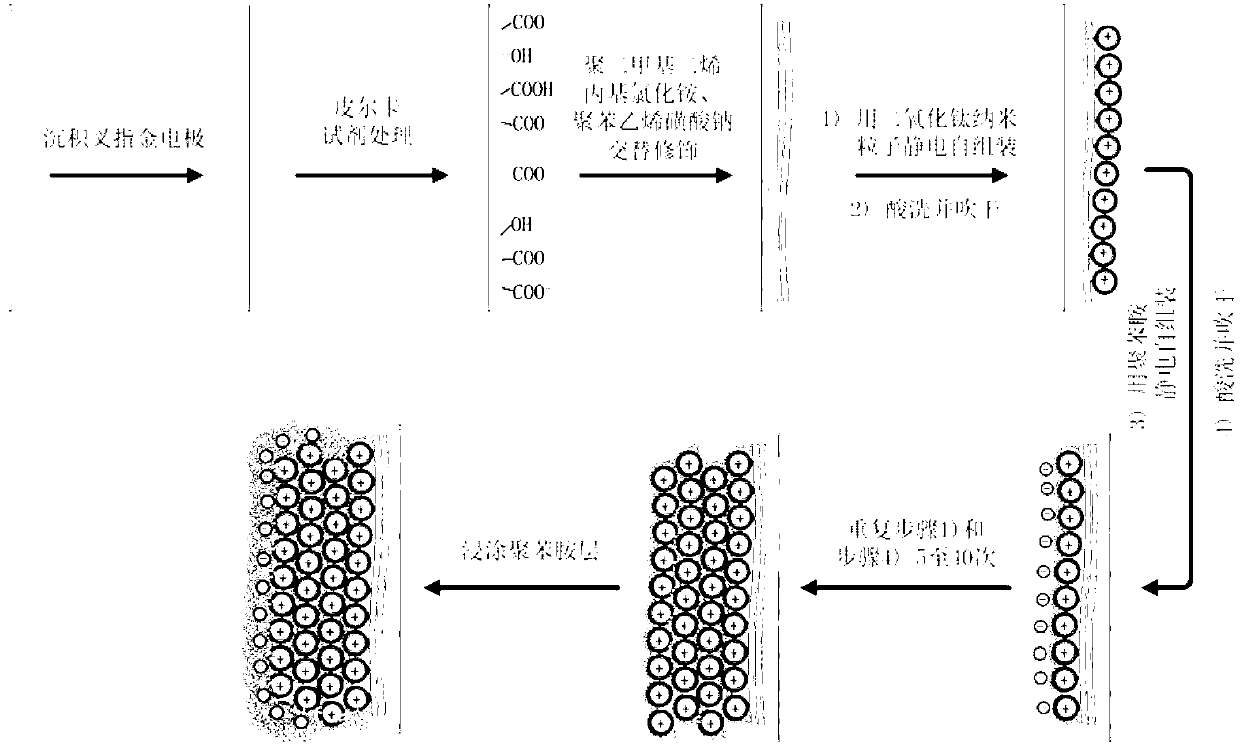

[0068] The present invention also provides a method for preparing a polyaniline / titanium dioxide nanocomposite impedance thin-film gas sensor, comprising the following steps:

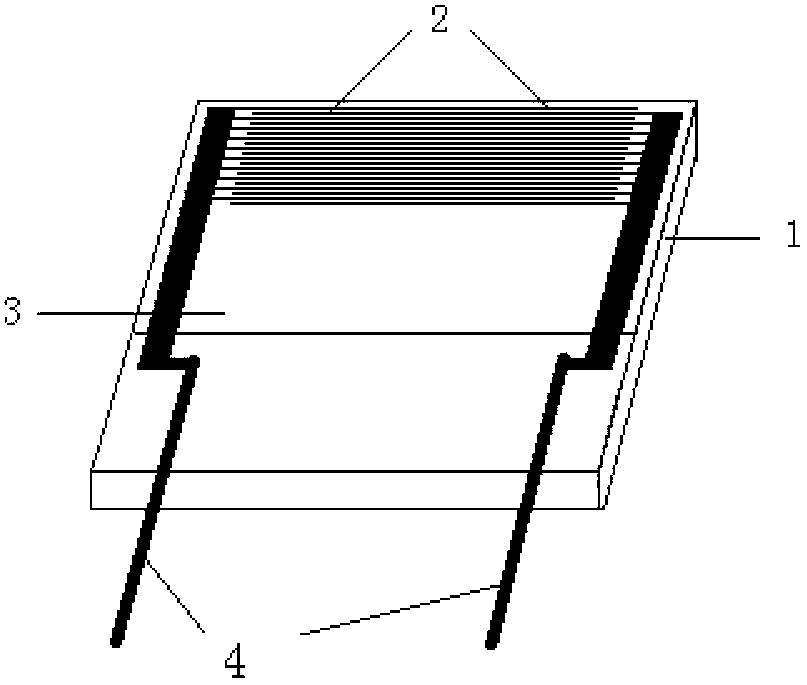

[0069] 1) Deposit interdigitated gold electrodes 2 on the surface of ceramic substrate 1 by evaporation or photolithography to prepare ceramic substrate 1 with interdigitated gold electrodes;

[0070] 2) processing the ceramic substrate 1 with interdigitated gold electrodes to obtain a modified ceramic substrate 1 with interdigitated gold electrodes;

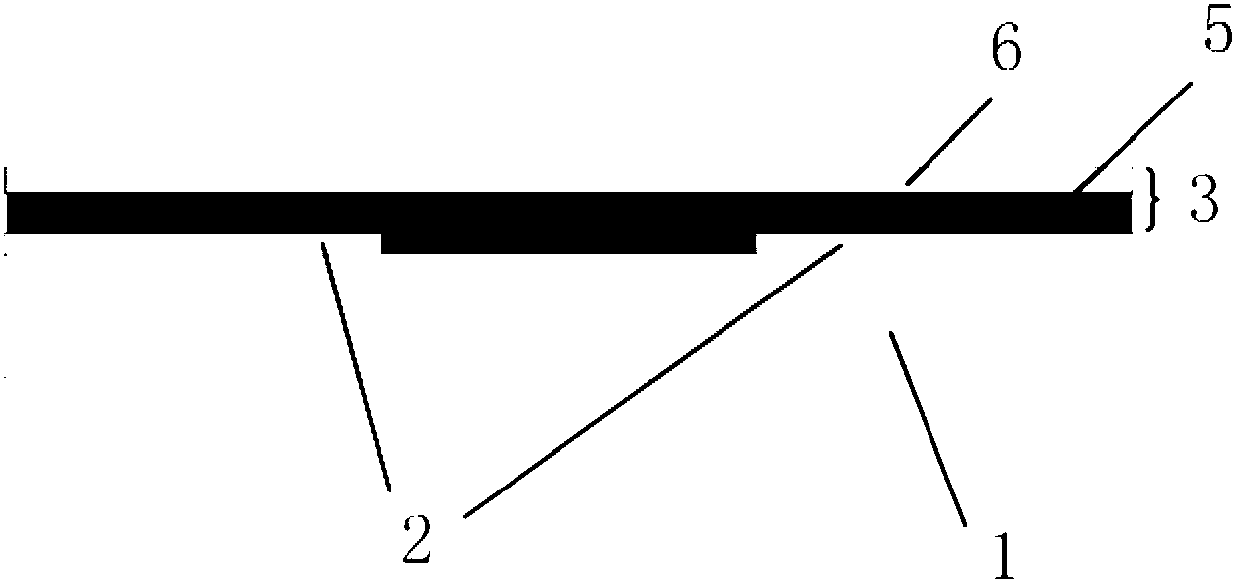

[0071] 3) Deposit polyaniline / titanium dioxide layer-by-layer electrostatic self-assembled composite film 5 on the modified ceramic substrate 1 with interdigitated gold electrodes;

[0072] 4) Deposit a polyaniline layer 6 on the polyaniline / titanium dioxide layer-by-layer electrostatic self-assembled composite film 5 to prepare a polyaniline / titanium dioxide nanocomposite resistive thin film gas sensor.

[0073] The number of interdigitated gold electro...

Embodiment 1

[0076] (1) Deposit 5 pairs of interdigitated gold electrodes 2 with a width of 200 μm and an interdigital gap of 200 μm by evaporation on the surface of the ceramic substrate 1 to obtain a ceramic substrate 1 with interdigitated gold electrodes;

[0077] (2) with Piranha solution (from 7 parts by volume of concentrated sulfuric acid (H 2 SO4) and 3 parts of 30% hydrogen peroxide (H 2 o 2 ) consists of) soaking the ceramic substrate with interdigitated gold electrodes at room temperature for 30 minutes, rinsing with deionized water for 2 minutes, and drying with nitrogen;

[0078] (3) Immerse the dried ceramic substrate 1 with a concentration of 2%wt in an aqueous solution of polydimethyldiallylammonium chloride for 5 minutes, take it out and rinse it with deionized water for 1 minute and dry it with nitrogen;

[0079] (4) Immerse the dried ceramic substrate 1 prepared in step (3) into sodium polystyrene sulfonate with a concentration of 2%wt for 10 minutes, take out and rins...

Embodiment 2

[0089] Step (9): Repeat step (7) and step (8) 5 times in sequence, and the remaining conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com