Graphene, silver phosphate and titanium dioxide dual-functional composite and method for preparing same

A composite material and titanium dioxide technology, applied in chemical instruments and methods, botanical equipment and methods, water/sludge/sewage treatment, etc., to achieve uniform size, prevent large-area agglomeration, and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

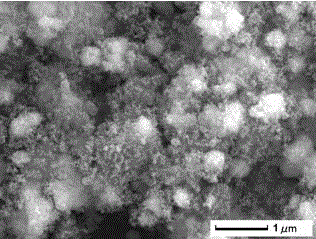

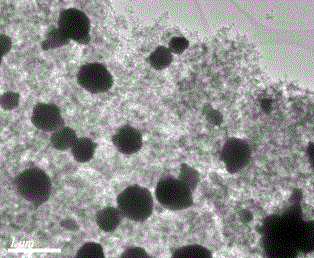

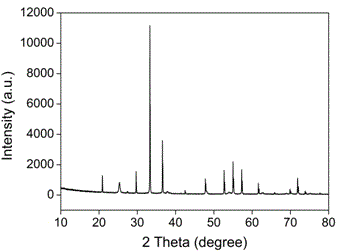

Image

Examples

Embodiment 1

[0025] Disperse 20 mg of graphene oxide in 20 ml of deionized water and sonicate for 3 hours to obtain a graphene oxide dispersion, weigh 1.529 g of silver nitrate and dissolve it in 20 ml of deionized water to obtain a silver nitrate solution, and dissolve the silver nitrate solution under magnetic stirring conditions Add it dropwise to the above-mentioned graphene oxide dispersion, and stir the solution slowly for 6 hours after the addition is complete, to obtain a mixed solution A; then weigh 300 mg P25 and ultrasonically disperse it in 50ml deionized water, and dissolve the P25 dispersion under magnetic stirring conditions After being added dropwise in mixed solution A, continue to stir for 30 minutes to obtain mixed precursor solution B, weigh 0.426 g Na 2 HPO 4 Dissolve the solid in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, then add the prepared disodium hydrogen phosphate solution to the mixed precursor solution B dropwise until the reac...

Embodiment 2

[0028] Disperse 50 mg graphene oxide in 20 ml deionized water and sonicate for 4 hours to obtain a graphene oxide dispersion, weigh 1.529 g silver nitrate and dissolve it in 20 ml deionized water to obtain a silver nitrate solution, and dissolve the silver nitrate solution under magnetic stirring conditions Add dropwise to the above-mentioned graphene oxide dispersion. After the dropwise addition, the solution was slowly stirred for 12 hours to obtain a mixed solution A. Then, 400 mg of P25 was ultrasonically dispersed in 50 ml of deionized water, and the P25 dispersion was mixed under magnetic stirring conditions. After being added dropwise in mixed solution A, continue to stir for 30 minutes to obtain mixed precursor solution B, weigh 0.36 g NaH 2 PO 4Dissolve the solid in 20 ml of deionized water to obtain a sodium dihydrogen phosphate solution, and then add the prepared sodium dihydrogen phosphate solution to the mixed precursor solution B drop by drop until the reaction s...

Embodiment 3

[0030] Disperse 100 mg of graphene oxide in 50 ml of deionized water and ultrasonically obtain a graphene oxide dispersion for 5 hours, weigh 1.529 g of silver nitrate and dissolve it in 20 ml of deionized water to obtain a silver nitrate solution, and dissolve the silver nitrate solution under magnetic stirring conditions Add dropwise to the above-mentioned graphene oxide dispersion, after the dropwise addition, the solution was slowly stirred for 8 hours to obtain a mixed solution A, then weigh 600 mg P25 and ultrasonically disperse it in 50ml deionized water, and dissolve the P25 dispersion under magnetic stirring conditions After being added dropwise in mixed solution A, continue to stir for 30 minutes to obtain mixed precursor solution B, weigh 0.426 g Na 2 HPO 4 The solid was dissolved in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and then the prepared disodium hydrogen phosphate solution was added dropwise to the mixed precursor solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com