Method for preparing graphene and titanium dioxide composite material by vapor phase reduction method

A technology of titanium dioxide and composite materials, applied in the direction of titanium dioxide, graphene, titanium oxide/hydroxide, etc., to achieve the effect of increasing porosity, improving electrical conductivity, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

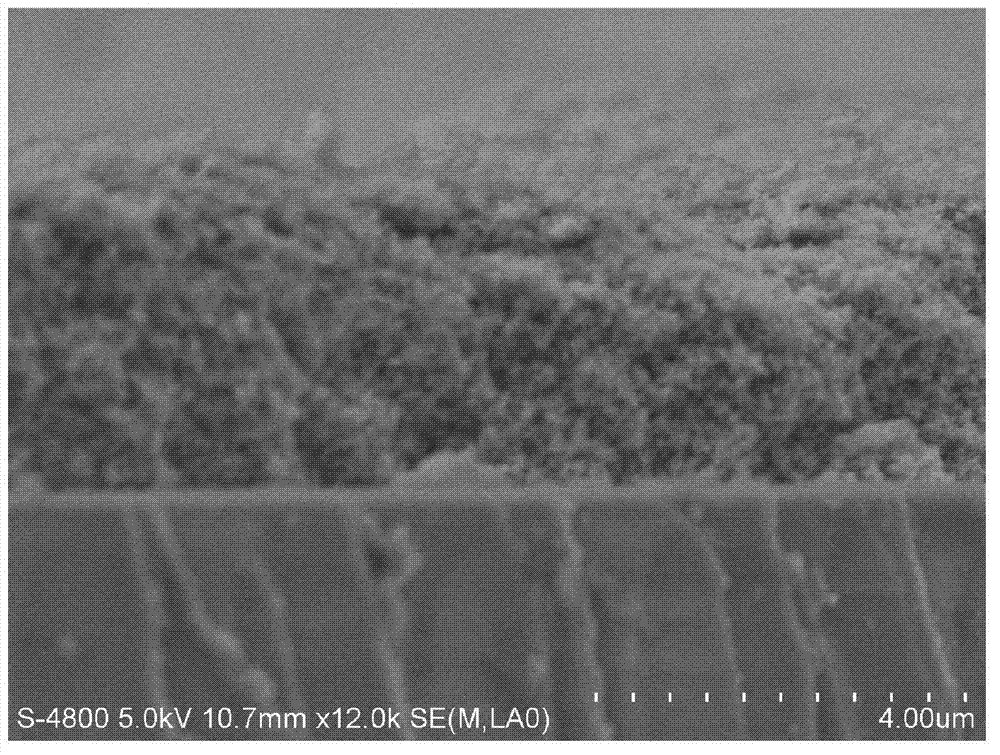

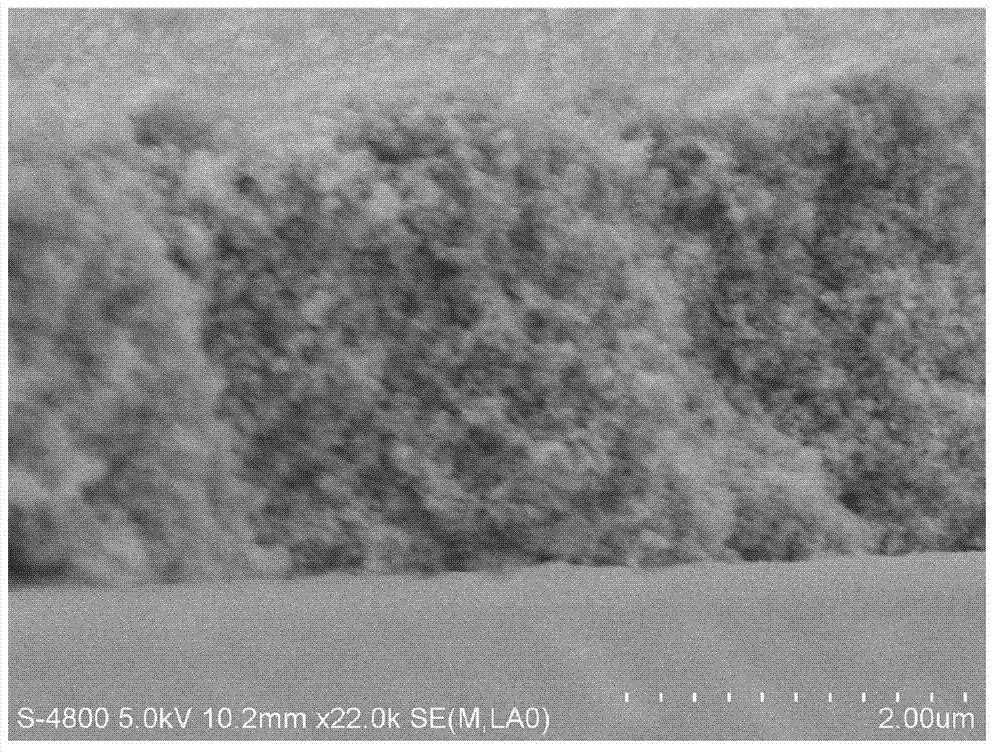

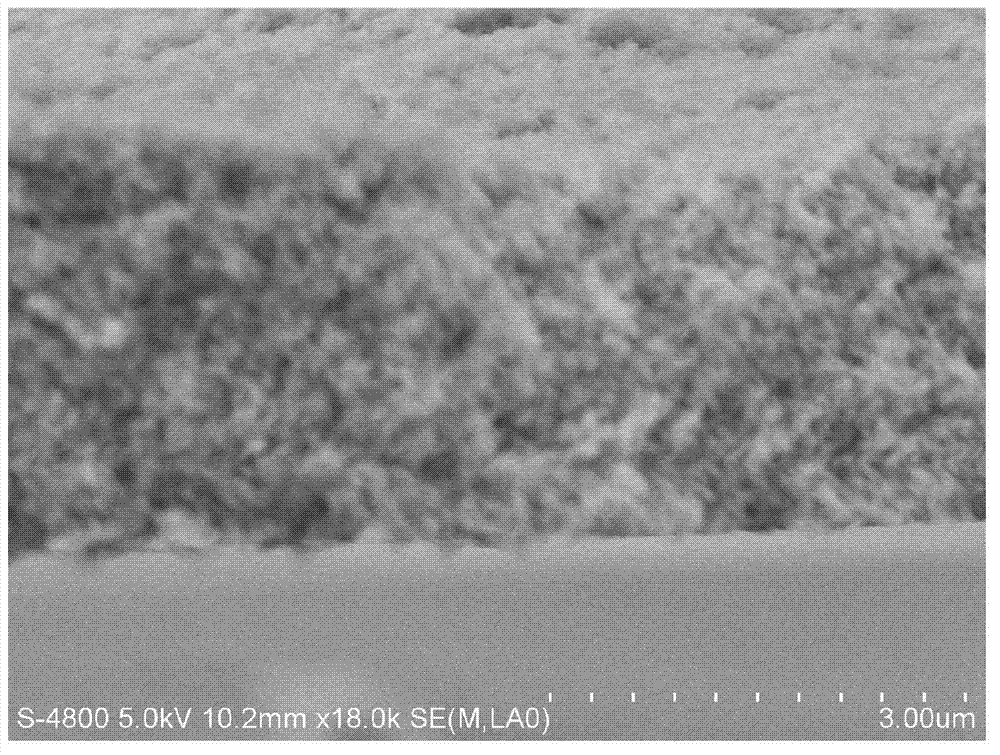

Image

Examples

Embodiment 1

[0024] 1) Acidification treatment: Titanium dioxide powder is pretreated. The acid solution is nitric acid with a mass concentration of 10%. The acid solution has a mass of 6g and is added dropwise to 6g of titanium dioxide powder. The average particle size of titanium dioxide is 1nm.

[0025] (2) Preparation of slurry: Prepare a graphene oxide solution with a concentration of 0.1g / L, and add it dropwise to the titanium dioxide slurry in step (1). After adding the graphene oxide solution to 60L, add 6g of methanol dropwise organic solvent, stir.

[0026] (3) Curing slurry: Add curing agent polyethylene glycol (polymerization degree: 2000) and p-isooctylphenyl ether (abbreviation: Laton X-100) to the slurry in step (2), the amount added 3g and 3g respectively, then stir. Add 6g high molecular polymer again, high molecular polymer is methyl cellulose, stir.

[0027] (4) Concentrated slurry: the slurry obtained in step (3) was distilled at 80°C to obtain a graphene-composite ti...

Embodiment 2

[0031] 1) Acidification treatment: use nitric acid with a mass concentration of 90% of the acid solution, the mass of the acid solution is 100g, and add it dropwise to 1g of titanium dioxide powder. The average particle size of titanium dioxide is 100μm.

[0032] (2) Preparation of slurry: prepare graphene oxide solution, the concentration of graphene oxide solution is 100g / L, add it to the titanium dioxide powder in step (1), after adding to 1L, add an organic solvent, the organic solvent is methanol and The addition amount of isopropanol, organic solution is respectively 50g and 50g, then stirs.

[0033] (3) Curing slurry: Add curing agent polyethylene glycol (polymerization degree: 20,000) and alkylphenol polyoxyethylene ether (abbreviation: OP-10 emulsifier) to the container in step (2), and the addition amount is After 50g and 50g, then stir, then add macromolecular polymer, macromolecular polymer is methyl cellulose and hydroxypropyl cellulose, respective quality is re...

Embodiment 3

[0038] (1) Acidification treatment: add 100 g of nitric acid solution with a mass concentration of 65% to 100 g of titanium dioxide powder dropwise, and the average particle size of titanium dioxide is 10 μm.

[0039] (2) Preparation of slurry: prepare a graphene oxide solution with a concentration of 1g / L, add dropwise to the titanium dioxide powder in step (1), add 22g of methanol and 72g of ethanol dropwise as an organic solvent after adding to 1L , then stir.

[0040] (3) Curing slurry: add curing agent terpineol and alkylphenol polyoxyethylene ether (referred to as OP-10 emulsifier) to the container in step (2), the addition amount is 500g and 500g respectively, then stir, add High molecular polymer, high molecular polymer is methyl cellulose and ethyl cellulose, the respective quality is 500g and 500g, stirs.

[0041] (4) Concentrated slurry: the slurry obtained in step (3) was distilled at 30°C to obtain graphene-composite titanium dioxide slurry, the concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com