Polyamino acid grafted copolymer and preparation method thereof

A graft copolymer and polyamino acid technology, applied in the field of polyamino acids, can solve the problems of deposition, lack of stabilizer protection, etc., and achieve the effects of not easy deposition, good biocompatibility and degradability, and easy drug carrying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

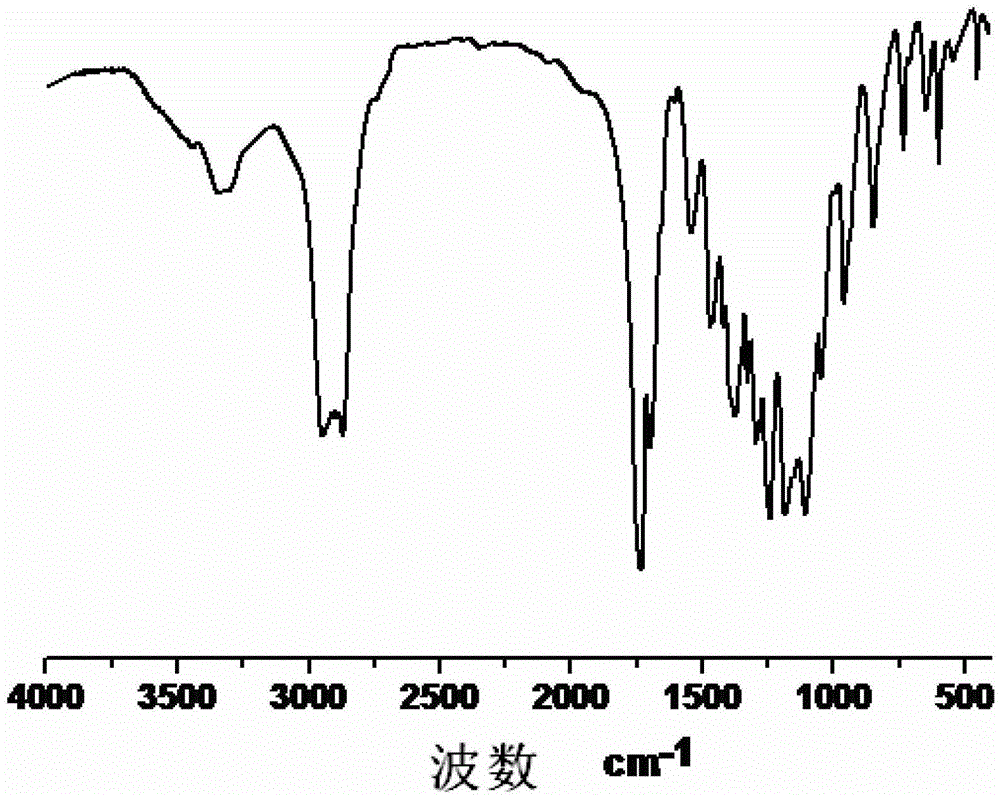

[0059] The present invention also provides a kind of preparation method of polyamino acid graft copolymer, comprising:

[0060] react polyamino acid, hydrophilic compound and hydrophobic compound under the action of condensation accelerator to obtain polyamino acid graft copolymer as shown in formula (I);

[0061] The polyamino acid is polyglutamic acid, polyaspartic acid or polyglutamic acid-polyaspartic acid copolymer;

[0062] The hydrophilic compound is any one of the compounds shown in formulas (5) to (8);

[0063] The hydrophobic compound is a hydroxyl-containing polyester, a C8-C30 fatty alcohol, or a biologically active small biomolecule;

[0064]

[0065]

[0066] Wherein, L is independently selected from methylene or ethylene;

[0067] R 1 is a group shown in formula (1) to formula (4);

[0068] R 2 It is a group other than a hydroxyl group of a polyester containing a hydroxyl group, a C8~C30 alkyl group, an aryl group, a C8~C30 alkenyl group, a C8~C30 alk...

Embodiment 1~3

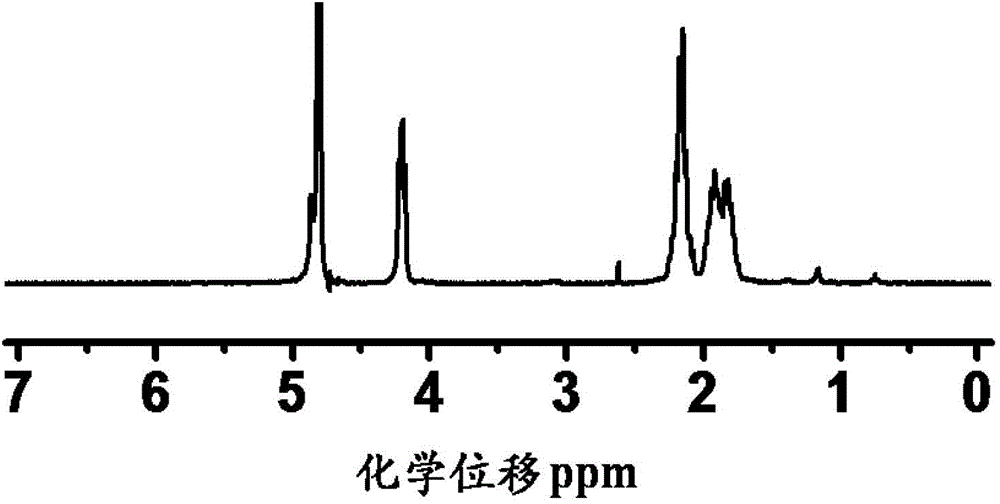

[0081] Add 2.63g (0.01mol) of γ-benzyl-L-glutamate-N-internal carboxylic acid anhydride monomer and 30mL of anhydrous N,N-dimethylformamide into the reaction flask respectively, and stir to dissolve. 0.0002 mol, 0.0001 mol and 0.00005 mol of n-hexylamine were added under stirring conditions, and the reaction was continued for 72 hours under stirring at 25°C. After the reaction, the reaction mixture was settled with 300 mL ether, filtered, washed three times with ether, and vacuum-dried at room temperature for 24 hours to obtain intermediate products, namely poly(γ-benzyl-L-glutamate).

[0082] The poly(γ-benzyl-L-glutamate) was analyzed by nuclear magnetic resonance with deuterated trifluoroacetic acid as a solvent, and its number-average molecular weight and average degree of polymerization were calculated according to the nuclear magnetic resonance spectrum. For the results, see Table 1.

[0083] Table 1 Number-average molecular weight, average degree of polymerization and ...

Embodiment 4~6

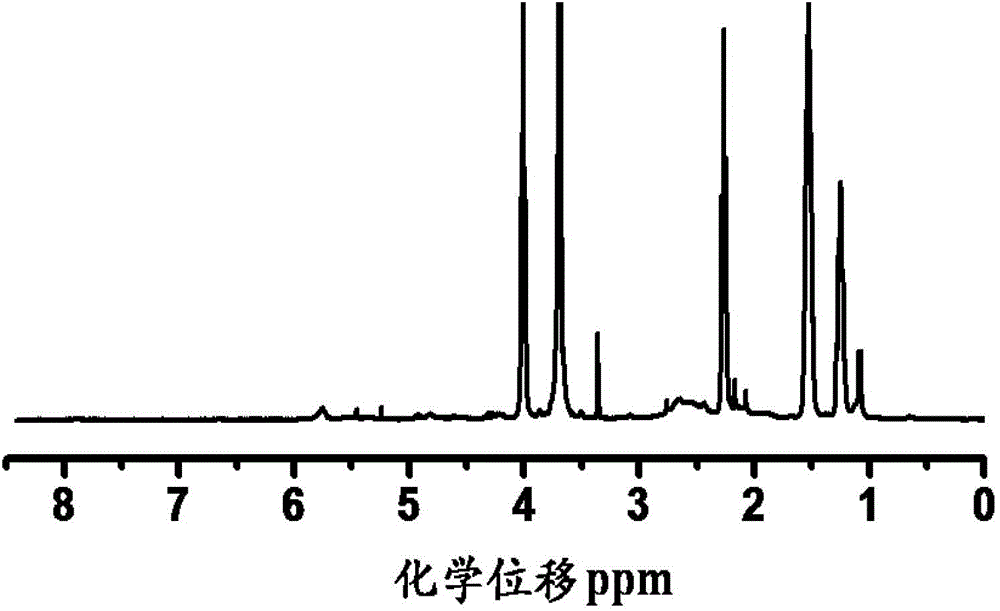

[0091]Add 2.49g (0.01mol) of γ-benzyl-L-aspartic acid ester-N-internal carboxylic acid anhydride monomer and 30mL of anhydrous N,N-dimethylformamide to the three reaction flasks respectively, Stir to dissolve. Under the condition of stirring, 0.0002 mol, 0.0001 mol and 0.00005 mol of n-hexylamine were respectively added to the three reaction flasks, and the reaction was continued for 72 hours under stirring at 25°C. After the reaction, the reaction mixture was settled with 300 mL ether, filtered, washed three times with ether, and dried in vacuum at room temperature for 24 hours to obtain intermediate products, namely poly(γ-benzyl-L-aspartic acid ester).

[0092] Dissolve 1 g of the above-mentioned poly(γ-benzyl-L-aspartic acid ester) in 10 mL of dichloroacetic acid, and add 3 mL of hydrogen bromide / glacial acetic acid solution with a mass content of 33% under stirring conditions to obtain a reaction mixture After the reaction mixture was stirred at 25°C for 1 h, the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com