White carbon black rubber reinforcer and preparation method thereof

A technology of rubber reinforcing agent and white carbon black, which is applied in the field of rubber reinforcing agent, can solve the problems of no high-dispersion product process exploration, etc., achieve good performance and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Drugs: sodium silicate nonahydrate (product of Sinopharm Chemical Reagent Co., Ltd., AR), absolute ethanol (product of Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (product of Xiamen Xinhongli Industrial Co., Ltd., purity>98%) .

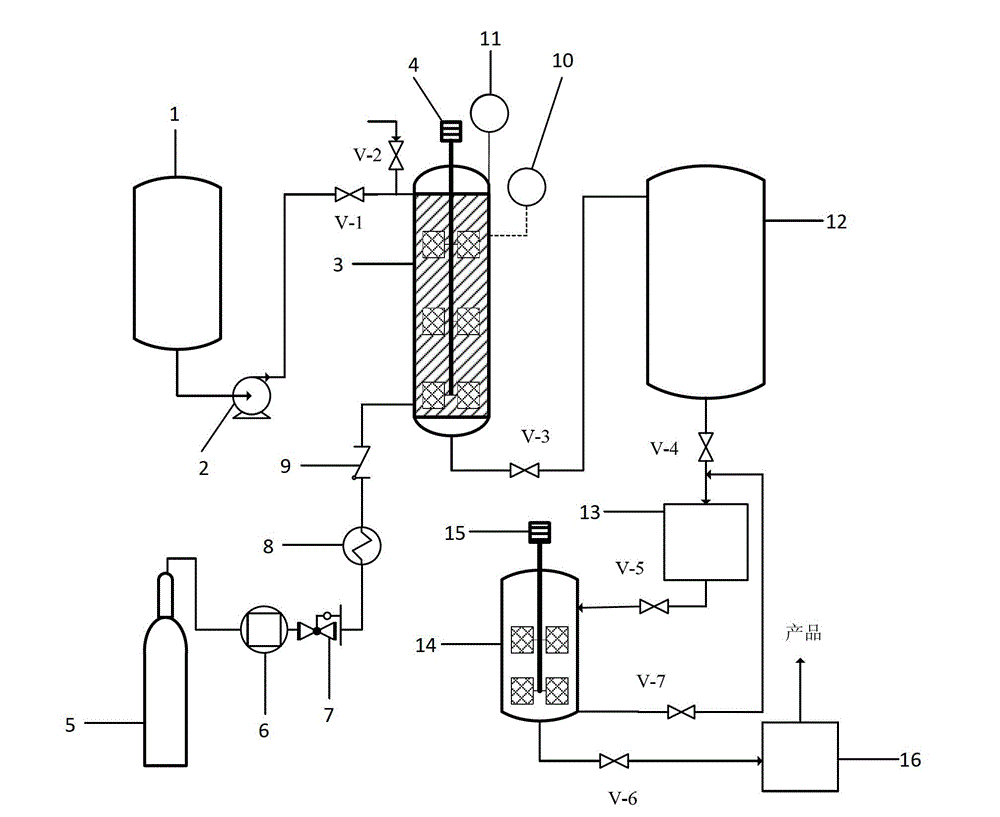

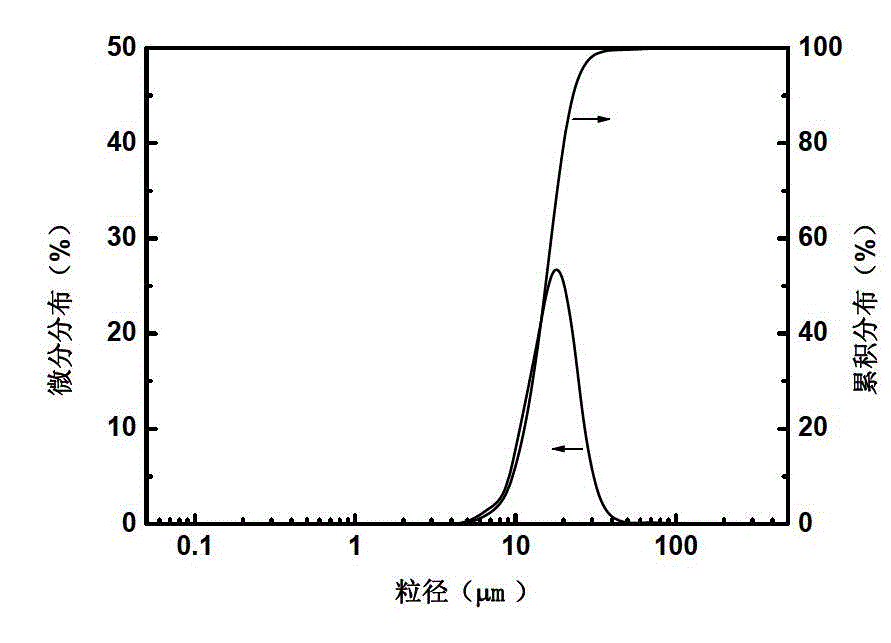

[0050] see figure 1 , figure 2 , image 3 , Figure 8 with Figure 9 , Weigh the solid sodium silicate and dissolve it in a certain amount of water, heat to promote dissolution, after all the solid sodium silicate is dissolved, cool to room temperature, filter to remove insoluble impurities, continue to add water, and configure the concentration of 1.0mol / L The water glass solution is pumped into the water glass solution storage tank for subsequent use. The water glass solution is pumped into a pressurized carbonization reaction kettle, and a surfactant (sodium dodecylsulfonate, by mass percentage, the surfactant is 0.2% of an aqueous solution of sodium silicate) and a silane coupling agent ( Bis[(triethoxysilyl)-propyl]tet...

Embodiment 2

[0052] Drugs: sodium silicate nonahydrate (product of Sinopharm Chemical Reagent Co., Ltd., AR), absolute ethanol (product of Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (product of Xiamen Xinhongli Industrial Co., Ltd., purity>98%) .

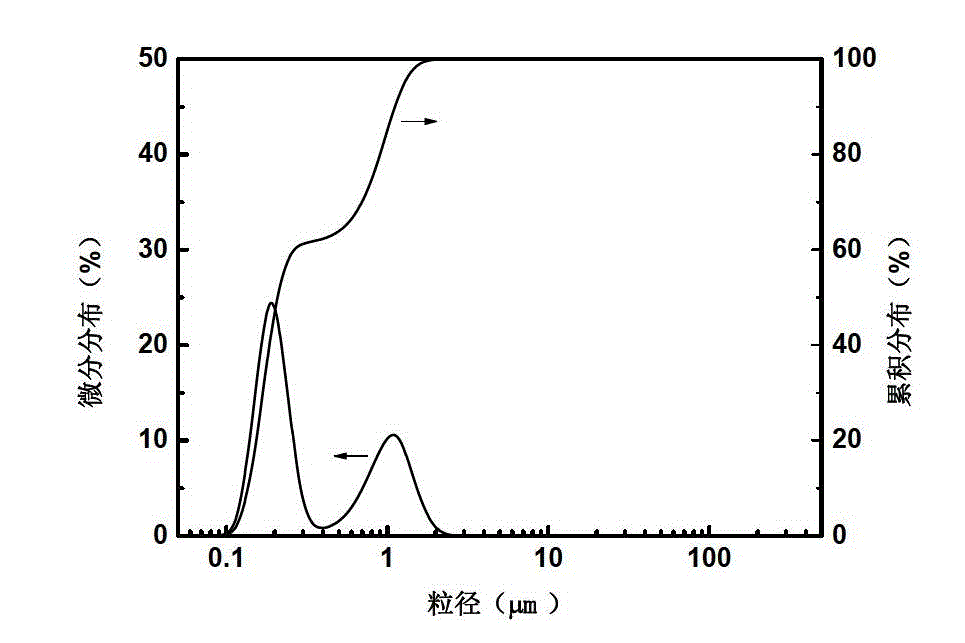

[0053] see figure 1 , Figure 4 , Figure 5 , Figure 10 with Figure 11 , weigh the solid sodium silicate and dissolve it in a certain amount of deionized water, heat to promote dissolution, after all the solid sodium silicate is dissolved in deionized water, cool to room temperature, filter to remove insoluble impurities, continue to add deionized water, configure Become the water glass solution that concentration is 1.0mol / L, pump into the water glass solution storage tank for subsequent use. The water glass solution is pumped into a pressurized carbonization reaction kettle, and a surfactant (sodium dodecylsulfonate, by mass percentage, the surfactant is 0.3% of an aqueous solution of sodium silicate) and a silane coupling ...

Embodiment 3

[0055] Drugs: sodium silicate nonahydrate (product of Sinopharm Chemical Reagent Co., Ltd., AR), absolute ethanol (product of Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (product of Xiamen Xinhongli Industrial Co., Ltd., purity>98%) .

[0056] see figure 1 , Image 6 , Figure 7 , Figure 12 with Figure 13 , weigh the solid sodium silicate and dissolve it in a certain amount of deionized water, heat to promote dissolution, after all the solid sodium silicate is dissolved in deionized water, cool to room temperature, filter to remove insoluble impurities, continue to add deionized water, configure Become the water glass solution that concentration is 0.5mol / L, pump into the water glass solution storage tank for subsequent use. The water glass solution is pumped into a pressurized carbonization reaction kettle, and a surfactant (sodium dodecylsulfonate, by mass percentage, the surfactant is 0.3% of an aqueous solution of sodium silicate) and a silane coupling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com