Food grade plasticizing polrvinyl chloride (PVC) glove and preparation method thereof

A polyvinyl chloride, food-grade technology, applied in the field of food-grade plasticized polyvinyl chloride gloves and its preparation, to achieve the effect of improving processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

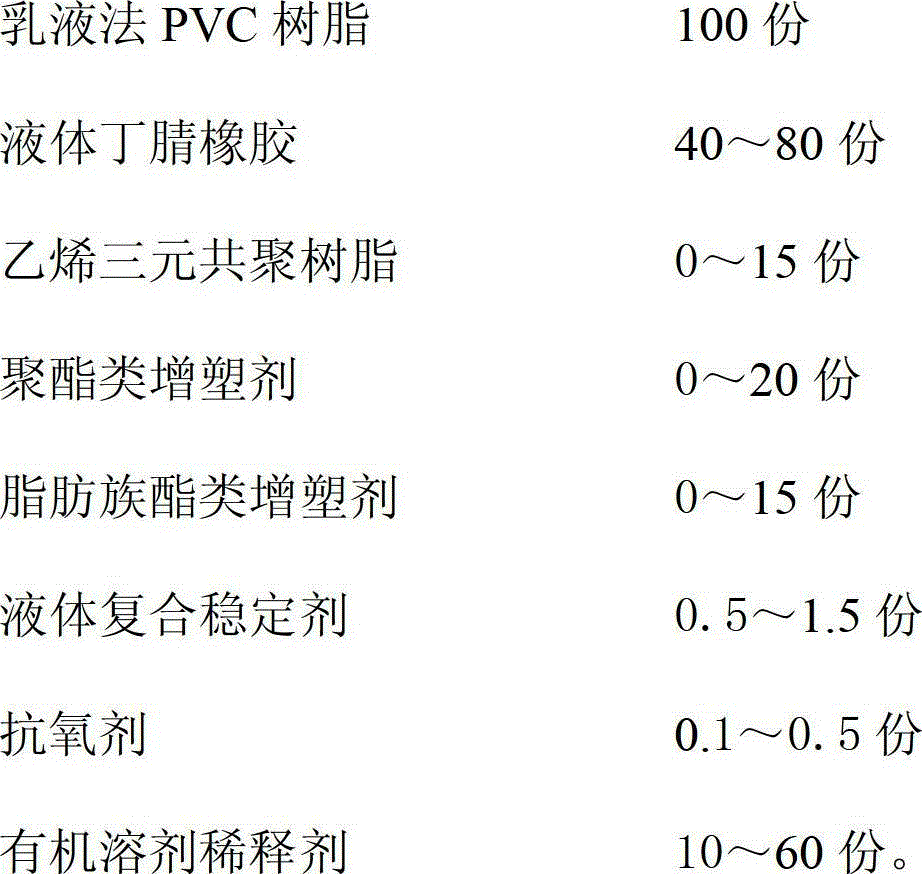

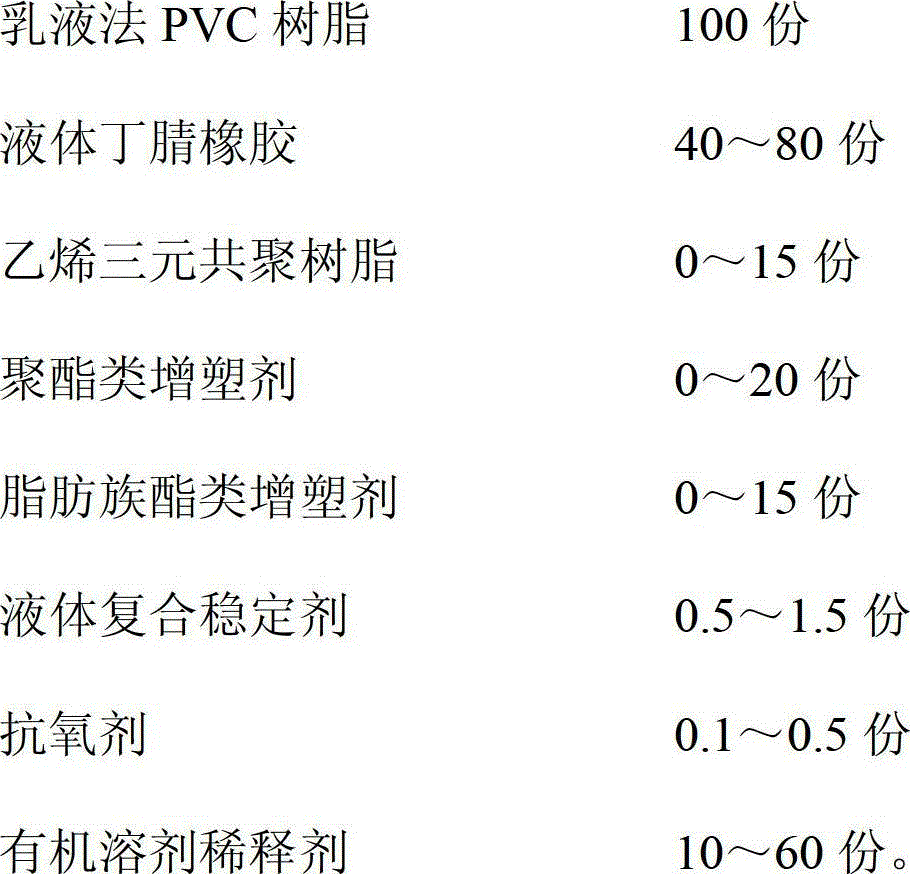

Method used

Image

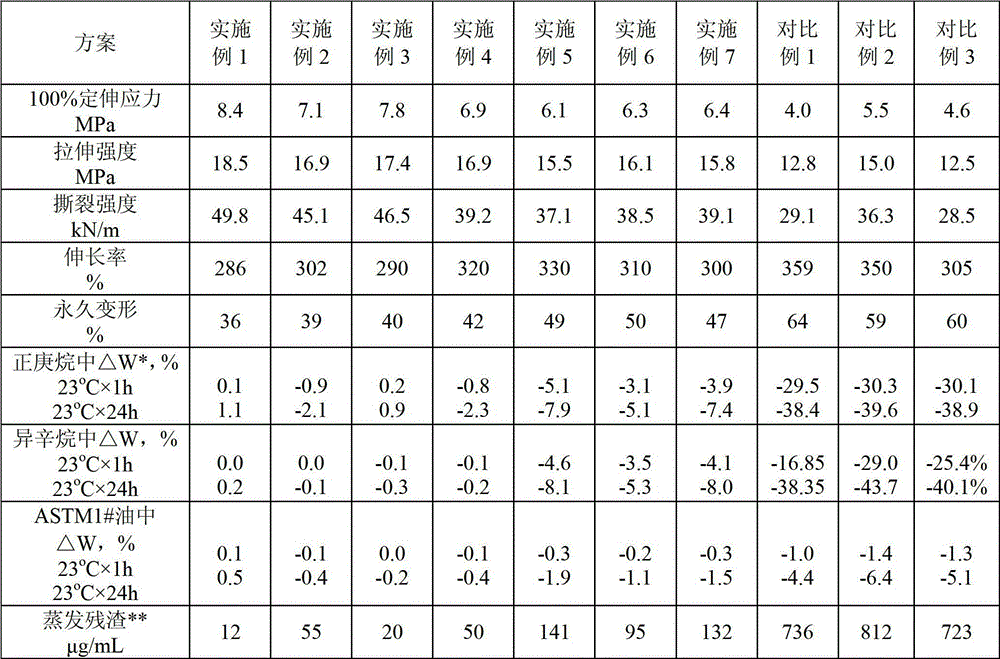

Examples

Embodiment 1

[0034] The mass ratio and parts of raw materials are: emulsion method PVC resin 100, liquid nitrile rubber (AN=40wt%, M n =2500) 80, Ca / Zn liquid composite stabilizer 0.8, organic calcium multiple complex stabilizer 0.4, antioxidant 10760.1, antioxidant 2640.1, n-hexane 10, acetone 15, butanone 10, tetrahydrofuran 15.

[0035] Preparation method: ①Add Ca / Zn liquid composite stabilizer and organic calcium multi-component composite stabilizer into a mixing tank, heat and stir at a stirring speed of 50r / min; when the temperature rises to 50°C, add antioxidants and continue stirring until the temperature rises When the temperature reaches 80°C, cool down the composite stabilized anti-oxidant functional additive containing the dissolved antioxidant before use. ② Add 100 parts of emulsion method PVC resin powder into the mixing tank, slowly inject 55 parts of liquid nitrile rubber, start stirring at a control speed of 300r / min, add the remaining 25 parts of liquid nitrile rubber aft...

Embodiment 2

[0037] The mass ratio and parts of raw materials are: emulsion method PVC resin 100, liquid nitrile rubber (AN=36wt%, M n =2000) 74, dioctyl adipate 3, dioctyl sebacate 3, Ca / Zn liquid composite stabilizer 0.6, organic magnesium multiple compound stabilizer 0.6, antioxidant 10100.1, antioxidant DLTP0.2 , Isooctane 10, n-heptane 5, acetone 20, tetrahydrofuran 10.

[0038] Preparation method: ①Add Ca / Zn liquid composite stabilizer and organomagnesium multi-component composite stabilizer into a mixing tank, heat and stir at a stirring speed of 80r / min; when the temperature rises to 60°C, add antioxidant 1010 and DLTP to continue stirring When the temperature rises to 120°C, cool down the compound stabilized anti-oxidant functional additive containing the dissolved antioxidant before use. ②Add 100 parts of emulsion method PVC resin powder into the mixing tank, then slowly inject 50 parts of liquid nitrile rubber, and start stirring at a control speed of 300r / min. After 12 minutes...

Embodiment 3

[0040] Raw material mass ratio and parts are: emulsion method PVC resin 100, liquid nitrile rubber (AN=33wt%, M n =2200) 65, polyester plasticizer polytrimethylene adipate (M n =1800, viscosity at 25°C=3Pa.s) 15, Ca / Zn liquid composite stabilizer 0.6, organic calcium multiple compound stabilizer 0.3, organic magnesium multiple compound stabilizer 0.3, antioxidant DSTP0.15, antioxidant DLTP0.15, isooctane 5, ethyl acetate 15, acetone 10, butanone 10, tetrahydrofuran 5.

[0041] Preparation method: ① Add Ca / Zn liquid composite stabilizer, organic calcium multi-component compound stabilizer, and organic magnesium multi-component compound stabilizer into the mixing tank and heat and stir at a stirring speed of 100r / min; when the temperature rises to 50°C, put Continue to stir the antioxidants DSTP and DLTP until the temperature rises to 85°C, and cool the composite stabilized antioxidant functional additive containing dissolved antioxidants before use. ② Add 100 parts of emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com