Carbon nanotube/short-fiber composited nano-carbon paper and continuous preparation method thereof

A carbon nanotube and nanocarbon technology, which is applied in the field of nanocarbon material preparation, can solve problems such as difficulty in preparing large-scale products, inability to improve preparation efficiency, and high brittleness of nanocarbon paper, and achieve simple process, broad commercialization prospects, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

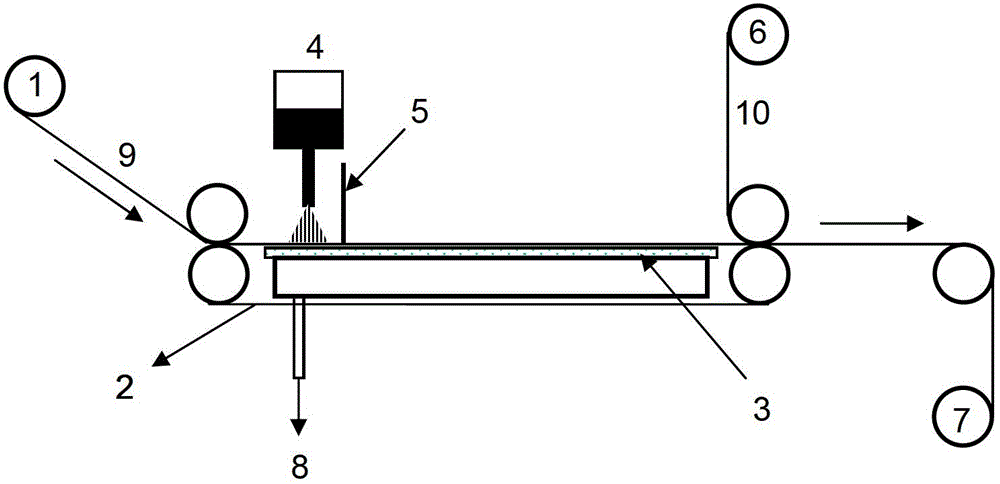

[0040] As another aspect of the technical solution of the present invention, the continuous preparation method of the carbon nanotube / short fiber composite nanocarbon paper comprises the following steps:

[0041] First, the carbon nanotubes are dispersed in a solvent with the aid of a dispersant to form a dispersion;

[0042] Subsequently, the short fibers are slowly mixed into the dispersion liquid under low-speed stirring, and the short fibers are well dispersed by high-speed shearing to obtain a slurry;

[0043] Then, the above-mentioned slurry is formed into a film by vacuum-assisted casting to form an initial composite nano-carbon paper, and the dispersant is removed through post-treatment to obtain a composite nano-carbon paper.

[0044] Further, the dispersion process of the aforementioned carbon nanotubes may adopt any one of high-speed shear dispersion, ultrasonic dispersion, grinding dispersion and ball mill dispersion, but is not limited thereto.

[0045] The foreg...

Embodiment 1

[0052] Example 1 Weigh 30 grams of multi-walled carbon nanotubes, dissolve them in 1 liter of Triton-100 aqueous solution with a concentration of 1%, then use a grinder to grind and disperse, stir and disperse at a speed of 3000 rpm for 1 hour, and sieve through a 200-mesh filter to obtain Uniform carbon nanotube dispersion ("dispersion" for short); add 5 grams of chopped carbon fibers with a length of 3 mm in slow stirring, and the weight ratio of carbon nanotubes to carbon fibers is 6:1. Disperse in a cutting disperser with a rotation speed of 3000 rpm, disperse for 20 minutes to form a stable slurry, and stand for 20 minutes to defoam before proceeding to film-forming processing. Afterwards, an initial composite nano-carbon paper with a thickness of 70 microns was prepared by means of a vacuum-assisted casting film-forming device, and the polymer was washed off after subsequent leaching, and the carbon paper could be directly peeled off from the filter membrane to obtain a...

Embodiment 2

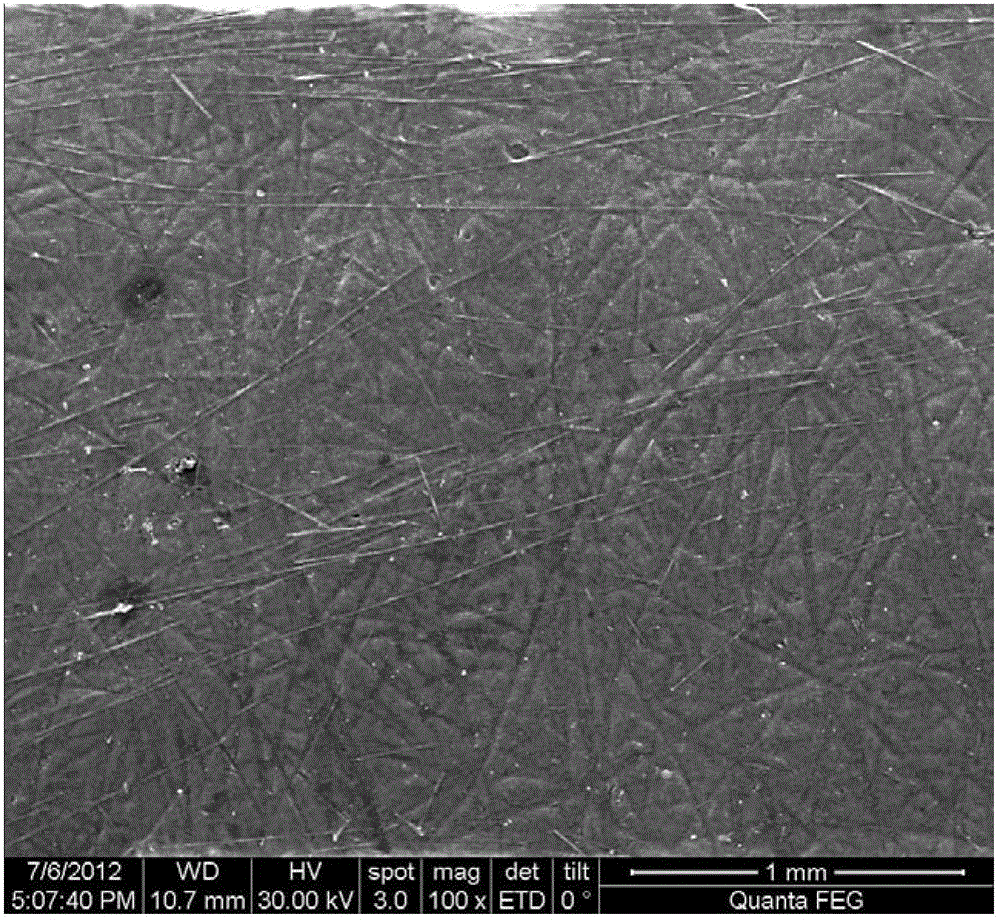

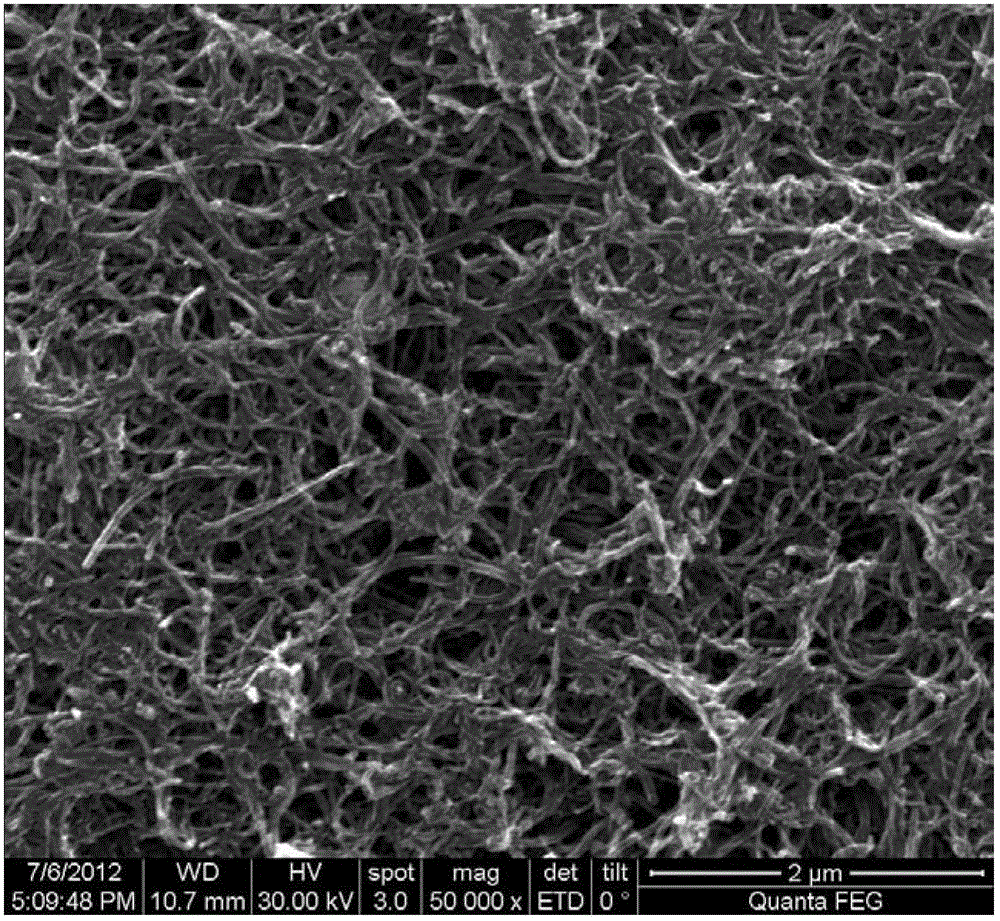

[0054] Example 2 This embodiment is basically the same as Embodiment 1, the difference is that the weight ratio of carbon nanotubes to carbon fibers is 8:1, Figure 3a-Figure 3c Shown is the scanning electron micrograph of the carbon nano paper prepared in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com