Photoinduced polymer holographic recording material and preparation method thereof

A holographic recording material and photopolymer technology, which is applied in the direction of photomechanical equipment, optics, pattern surface photoplate making process, etc., can solve the problems of affecting the safety of operators, polluting the environment, and being unable to industrialize production, etc., and achieves wide application Foreground, simple operation, short production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Under the protection of the green light, in a 500ml container, add 0.8g of 1,3:2,4-dibenzylidene-D-sorbitol, 30g of hydroxyethyl methacrylate, 30g of triethylene glycol dimethacrylate, 20g of nano-titanium dioxide (prepared according to the literature [advfunct mater 2005, 15, 1623-1629]), 0.12g of methylene blue, and 2.0g of N-methyldiethanolamine were stirred and mixed uniformly at 80°C. Then, the mixed solution is coated on the glass surface with a manual coating bar at 80°C, with a film thickness of 50 microns, and then the temperature is lowered to 30°C to gel, and a photopolymer that can be used for holographic recording is prepared. dry film. A 50-micron PET film is used to cover the surface, a 632.8nm He-Ne laser is used as a light source, a coin is used as a real object, and a transmission holographic imaging method is adopted, with a reference light intensity of 5mW / cm 2 , the maximum light intensity in the object light is 3mW / cm 2 , the angle between the tw...

Embodiment 2

[0031] Under the protection of the green light, add 0.8g of 1,3:2,4-dibenzylidene-D-sorbitol, 30g of hydroxyethyl methacrylate, triethylene glycol dimethyl 30g of acrylate, 20g of p-amylbiphenylcyanide, 0.12g of methylene blue, and 2.0g of N-methyldiethanolamine were stirred and mixed uniformly at 80°C. Then, the mixed solution is coated on the glass surface with a manual coating bar at 80°C, with a film thickness of 50 microns, and then the temperature is lowered to 30°C to gel, and a photopolymer that can be used for holographic recording is prepared. dry film. A 50-micron PET film is used to cover the surface, a 632.8nm He-Ne laser is used as a light source, a coin is used as a real object, and a transmission holographic imaging method is adopted, with a reference light intensity of 5mW / cm 2 , the maximum light intensity in the object light is 3mW / cm 2 , the angle between the two beams of light is 45°, and the image of the object can be obtained after exposing for 10s.

Embodiment 3

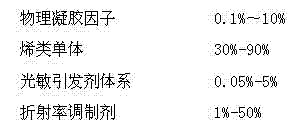

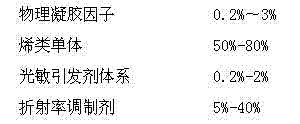

[0033] Prepare the photopolymer material according to the following formula:

[0034] Gel factor 1.6g Ethoxydiphenylfluorene diacrylate 30g o-Phenylphenylethoxyacrylate 30g Methylene blue 0.12g N-phenylglycine 2.0g 1-Butyl-3-methylimidazolium tetrafluoroborate 40g

[0035] The structural formula of gelatin is (n=1, m=17)

[0036] Under the protection of green light, in the environment of 80 ℃, the blending is uniform. Then, the mixed solution was coated on the glass surface under the environment of 80° C., and then the temperature was lowered to 30° C. for gelation, so as to obtain a photopolymer dry film that can be used for holographic recording. Cover the surface with a 50-micron PET film, use a 632.8nm He-Ne laser as the light source, take coins as objects, and use a reference light intensity of 10mW / cm 2 , the maximum light intensity of object light is 5mW / cm 2 , two beams of light are incident from different surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com