Efficient florfenicol powder composition and preparation method thereof

A technology of florfenicol and composition, which is applied in the field of high-efficiency florfenicol powder composition and its preparation, can solve the problems of unsatisfactory expected results and low solubility of florfenicol, achieve simple preparation method, improve antibacterial effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 500 g of florfenicol, dissolve it with 3000 mL of acetone, and set aside.

[0035] In addition, take 5 kg of florfenicol adsorption material lactose, dissolve it in 50 liters of water, then add 27 g of disodium salt of ethylenediaminetetraacetic acid, and dissolve 55 g of sodium lauryl sulfate; add the acetone solution of florfenicol to the above-mentioned In the solution containing lactose, stir quickly and spray quickly (spray conditions: the air inlet temperature is controlled at 150-180°C, the air outlet temperature is controlled at 40-50°C, the spray pressure is 0.5-0.6 Mpa, and the vacuum degree is controlled at 0-20 between Kpa), collect the product and dry it at 60-70°C for 5 hours to obtain the product.

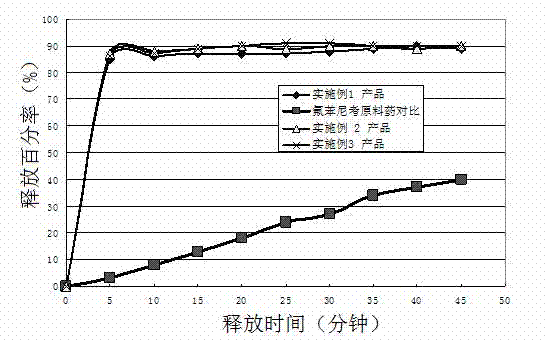

[0036] The product obtained is released in vitro according to conventional methods, compared with the florfenicol raw material drug, with water as the release medium, the HPLC method is used to measure the drug content, and the release percentage at each...

Embodiment 2

[0039] Weigh and take Florfenicol 100g, dissolve it with 5000mL of ethanol, and set aside.

[0040] In addition, take by weighing 5 kg of the porous micropowder silica gel of Florfenicol adsorption material, disperse with 50 liters of water, add EDTA disodium salt 10 g, sodium lauryl sulfate 50 g and dissolve; the ethanol solution of Florfenicol Add it into the suspension containing porous micro-powdered silica gel, stir quickly, and spray quickly (spray conditions: the air inlet temperature is controlled at 150-180°C, the air outlet temperature is controlled at 40-50°C, the spray pressure is 0.5-0.6 Mpa, the control The vacuum degree is between 0-20 Kpa), and the product is collected and dried at 60-70°C for 5 hours to obtain the product.

[0041] The product obtained is released in vitro according to conventional methods, compared with the florfenicol raw material drug, with water as the release medium, the HPLC method is used to measure the drug content, and the release perce...

Embodiment 3

[0044] Weigh and take Florfenicol 250g, dissolve with ethyl acetate 5000mL, set aside.

[0045] In addition, take by weighing 5 kg of florfenicol adsorption material cornstarch glue, disperse with 50 liters of water, add 55 g of disodium salt of edetate, and dissolve 10 g of sodium lauryl sulfate; the ethyl acetate of florfenicol Add the solution into the suspension containing cornstarch, stir quickly, and spray quickly (spray conditions: the air inlet temperature is controlled at 150-180°C, the air outlet temperature is controlled at 40-50°C, the spray pressure is 0.5-0.6 Mpa, and the vacuum is controlled The temperature is between 0 and 20 Kpa), and the product is collected and dried at 60 to 70°C for 5 hours to obtain the product.

[0046] The product obtained is released in vitro according to conventional methods, compared with the florfenicol raw material drug, with water as the release medium, the HPLC method is used to measure the drug content, and the release perce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com