Synthesis method and application of pinacolone catalyst composite support

A technology of composite carrier and synthesis method, applied in the field of catalysis, can solve problems such as low reaction temperature, and achieve the effects of lowering the reaction temperature, improving the activity and strength of the carrier, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Take a certain amount of aluminum salt (aluminum sulfate, aluminum nitrate, etc.) and titanium salt (titanium tetrachloride, titanium sulfate, etc.) Neutralize under the condition of value 7-8, wash the filter cake with water until the content of impurity ions is less than 0.1%, then dry the filter cake in an oven at 120°C for 8-12 hours and then crush it to less than 200 mesh, use an appropriate amount of nitric acid as a binder Shaped, extruded into strips of φ2mm, and calcined in a muffle furnace at 500-800°C for 5 hours to obtain the active alumina-titanium oxide composite carrier.

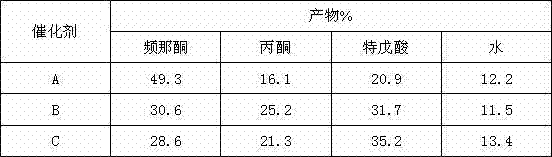

[0011]

Embodiment 2

[0013] Take a certain amount of titanium salt (titanium tetrachloride, titanium sulfate, etc.) The cake is washed with water until the content of impurity ions is less than 0.1%, then the filter cake is dried in an oven at 120°C for 8-12 hours, then crushed to less than 200 mesh, molded with an appropriate amount of nitric acid as a binder, extruded into strips of φ2mm, and placed in a muffle furnace Calcined at 500-800°C for 5 hours to obtain a titanium oxide carrier.

[0014]

Embodiment 3

[0016] Take a certain amount of aluminum salt (aluminum sulfate, aluminum nitrate, etc.) to make a solution, neutralize it with a precipitating agent (sodium hydroxide or sodium carbonate) at 60-70°C, pH 7-8, and wash the filter cake with water Until the content of impurity ions is less than 0.1%, then the filter cake is dried in an oven at 120°C for 8-12 hours, and then crushed to less than 200 meshes, molded with an appropriate amount of nitric acid as a binder, extruded into strips of φ2mm, and placed in a muffle furnace at 500- Calcined at 800°C for 5 hours to obtain activated alumina carrier.

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com