Toughening membrane with surface bump microstructure and preparation method thereof

A microstructure and toughening technology is applied in the field of toughened films with raised surface microstructures and their preparation, which can solve problems such as no toughened films, and achieve the improvement of impact-resistant delamination ability, toughening effect, and preparation. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028](1-1) Dissolve PEK-C (a phenolphthalein-modified polyaryletherketone) or PES in tetrahydrofuran to make a solution, and the mass percentage concentration of the solution is 5% or 20%;

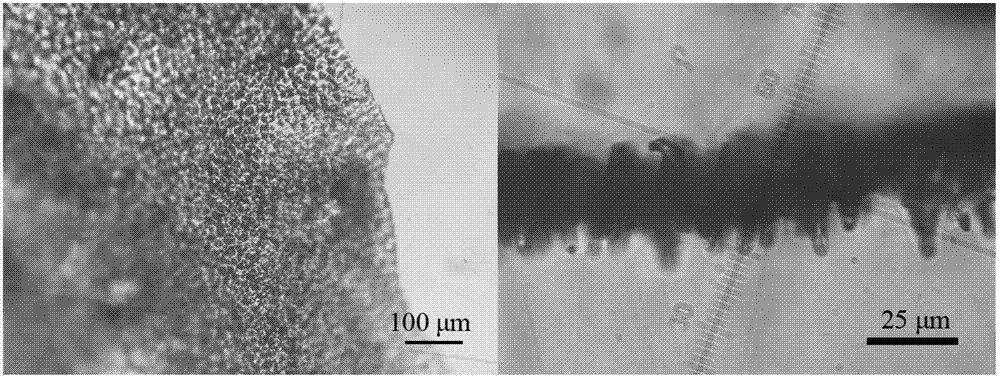

[0029] (1-2) Soft printing to obtain a film with a raised surface microstructure: add the solution dropwise to the structured side of the PDMS soft template with the microstructure of the lotus leaf surface reversely engraved. The raised height of the lotus leaf structure is 10~ 15μm, the width is 5μm, that is, the aspect ratio is 2~3, and then the two sides of the microstructure of the soft template that have been added with the solution are pressed together face to face, and kept at 30°C for 3min, and after peeling off, a double-sided Film with lotus leaf structure;

[0030] (1-3) Post-processing to obtain a toughened film: drying the film to remove residual solvent to obtain a toughened film with a raised microstructure on the surface;

[0031] (1-4) Drill the film with a mechanical p...

Embodiment 2

[0033] (2-1) Polyamic acid or polyetheramic acid or polyimide or polyetherimide precursor polymer such as polyamide ester or polyetheramide ester is dissolved in methanol to form a solution, polymerized The mass percent concentration of the precursor solution is 1% or 2%;

[0034] (2-2) Soft printing to obtain a film with a raised microstructure on the surface: add the solution dropwise to the structured side of the PDMS soft template with the surface microstructure of the grating reversed. The raised height of the grating is 5 μm or 10 μm, and the period 2 μm, that is, the aspect ratio is 2.5 or 5, take another film with a thickness of 7 μm made of this polymer precursor, and then press the microstructure of the two soft templates that have been added with the solution to face the surface of the film. On both sides, keep at 40°C for 5 minutes, and after peeling off, a polymer precursor film with surface convex microstructures on both sides is obtained;

[0035] (2-3) Post-tr...

Embodiment 3

[0038] (3-1) Dissolve polyethersulfone or polyetherimide in DMF to form a solution, and the mass percent concentration of the polymer solution is 15%;

[0039] (3-2) Soft printing to obtain a film with a raised microstructure on the surface: add the solution dropwise to the structured side of the soft template with a tetragonal lattice microstructure on the surface, and the raised height of the tetragonal lattice is 50 μm or 90 μm, the width is 10 μm, that is, the aspect ratio is 5 or 9, and the spacing between the bumps is 30 μm, and then this template is pressed on a PEK-C film placed on a soft template with a flat surface, the film The thickness is 15 μm. Then keep it at 110°C for 10 minutes, and peel it off to get a PES / PEK-C or PEI / PEK-C composite film with a square lattice on one side;

[0040] (3-3) Post-processing to obtain a toughened film: drying the film to remove residual solvent to obtain a toughened film with a raised microstructure on the surface;

[0041] (3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bump height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com