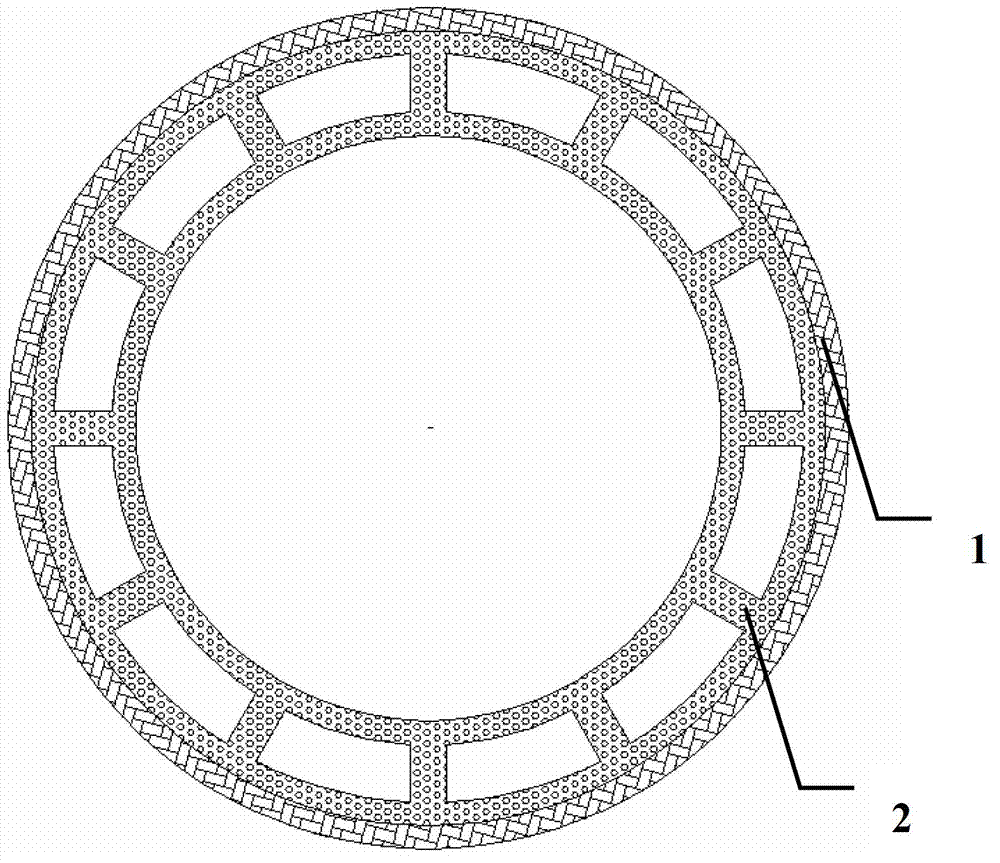

PET (Polyethylene Terephthalate) hollow foaming tubular product and manufacturing method thereof

A manufacturing method and technology of foamed tubes, applied in the direction of hoses, tubes, rigid tubes, etc., to achieve high crystallinity, improve surface brightness and weather resistance, and long-term storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the structural schematic diagram of the double-layer co-extruded composite structure, the PET outer layer formula is: 100 parts of polyethylene terephthalate (PET), 10 parts of active nano light calcium carbonate, 1.5 parts of polyethylene glycol glycidyl ether, 2 parts of masterbatch, PET hollow foam layer formula: 100 parts of polyethylene terephthalate (PET), 20 parts of active nano light calcium carbonate, 2.4 parts of polyethylene glycol glycidyl ether, 4 parts of color masterbatch 1.8 parts, 1.8 parts of azole complex foaming agent masterbatch, produce sample tube by the above-mentioned manufacturing method. After the test of the sample pipe, the tensile yield strength is 95MPa, the elastic modulus is 4380MPa, the heat distortion temperature (0.46Mpa) is 195-210°C, and the heat distortion temperature (1.8Mpa) is 190-200°C. The drainage noise of the system is 32dB, the 2000h weather resistance test performance maintains 99%, the color does not change, ...

Embodiment 2

[0024] According to the structural schematic diagram of the double-layer co-extruded composite structure, the PET outer layer formula is: 100 parts of polyethylene terephthalate (PET), 30 parts of active nano light calcium carbonate, 1.8 parts of polyethylene glycol glycidyl ether, 3 parts of color masterbatch, PET hollow foam layer formula: 100 parts of polyethylene terephthalate (PET), 8 parts of active nano light calcium carbonate, 1.8 parts of polyethylene glycol glycidyl ether, 3 parts of color masterbatch 1.2 parts, 1.2 parts of azole compound foaming agent masterbatch, produce sample tube by the above-mentioned manufacturing method. After testing the sample pipe, the tensile yield strength is 96.2MPa, the elastic modulus is 4680MPa, the heat distortion temperature (0.46Mpa) is 195-210°C, the heat distortion temperature (1.8Mpa) is 190-200°C, 4L water, 5m high The drainage noise of the system is 32dB, the performance of the 2000h weather resistance test is maintained at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com