Preparation method for nano-copper with oxidation resistance and dispersibility

A technology of anti-oxidation and dispersibility, applied in the field of nanomaterials, to achieve the effect of good monodispersity, uniform particle size, easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Disperse 3.70 g of copper glycinate and 0.02 g of dispersant sodium dodecylbenzenesulfonate in 300 mL of distilled water, and obtain a mixed solution by magnetic stirring and ultrasonic dispersion;

[0025] (2) Heat the above mixed solution to 25°C in a water bath under the action of magnetic stirring;

[0026] (3) Disperse 3.31 g of reducing agent sodium borohydride and 0.021 g of dispersant sodium dodecylbenzenesulfonate in 50 mL of distilled water, and stir to disperse;

[0027] (4) Add the mixture in step (3) dropwise to the mixture in step (2) for 30 seconds, then continue to react at 25°C for 3 hours;

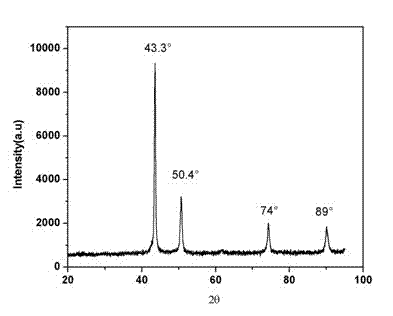

[0028] (5) The resulting suspension was centrifuged (10,000 rpm), washed twice with absolute ethanol and distilled water, and the resulting solid product was dispersed in 50 g of n-butanol and left to stand for 1 hour. XRD such as figure 1 As shown: the crystal phase of simple copper appears, no other copper oxides appear, and the surface has good oxidation r...

Embodiment 2

[0031] (1) Disperse 2.50 g of anhydrous cuprous acetate and 0.01 g of dispersant sodium dodecylbenzenesulfonate in 500 mL of distilled water, and obtain a mixed solution by magnetic stirring and ultrasonic dispersion;

[0032] (2) Heat the above mixed solution to 50°C in a water bath under the action of magnetic stirring;

[0033] (3) Disperse 1.56 g of sodium borohydride and 0.015 g of dispersant sodium dodecylbenzenesulfonate in 200 mL of distilled water, stir to disperse, and obtain a mixed solution;

[0034] (4) Add the mixture in step (3) dropwise to the mixture in step (2) for 90 seconds, then continue to react at 50°C for 3 hours;

[0035] (5) The resulting suspension was centrifuged (10,000 rpm), washed twice with absolute ethanol and distilled water, and the resulting solid product was dispersed in 20 g of tributyl phosphate and left to stand for 1 hour.

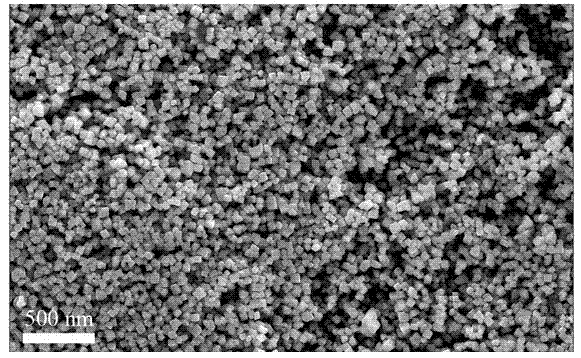

[0036] SEM detects the morphology and structure of copper nanoparticles, such as Figure 2A shown. The obtaine...

Embodiment 3

[0039] (1) Disperse 3.40 g of copper tartrate trihydrate and 0.10 g of dispersant sodium polyacrylate (molecular weight 3000) in 300 mL of distilled water, and obtain a mixed liquid by magnetic stirring and ultrasonic dispersion;

[0040] (2) Heat the above mixed solution to 75°C in a water bath under the action of magnetic stirring;

[0041] (3) Disperse 1.50 g of hydrazine hydrate and 0.24 g of dispersant sodium polyacrylate (molecular weight 3000) in 100 mL of distilled water, and stir to disperse;

[0042] (4) Add the mixture in step (3) dropwise to the mixture in step (2) for 50 seconds, then continue to react at 75°C for 3 hours;

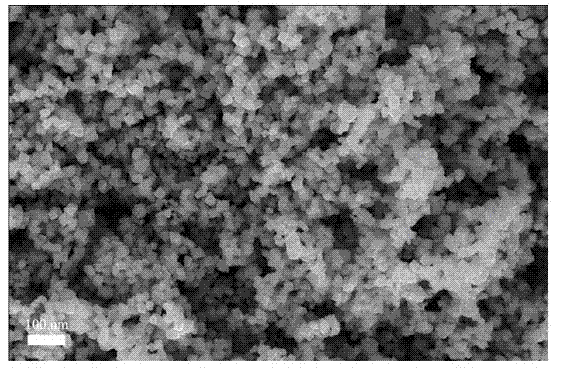

[0043] (5) The resulting suspension was centrifuged (rotating at 10,000 rpm), washed twice with absolute ethanol and distilled water, and the resulting solid product was dispersed in 50 g of oleic acid and left to stand for 1 hour. SEM detects the morphological structure of the obtained nano-copper particles, such as Figure 2B shown. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com