Novel microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic, a new type of technology, applied in the field of microwave dielectric ceramics, can solve the problems of volatile material density, damage to the performance of ceramic materials, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

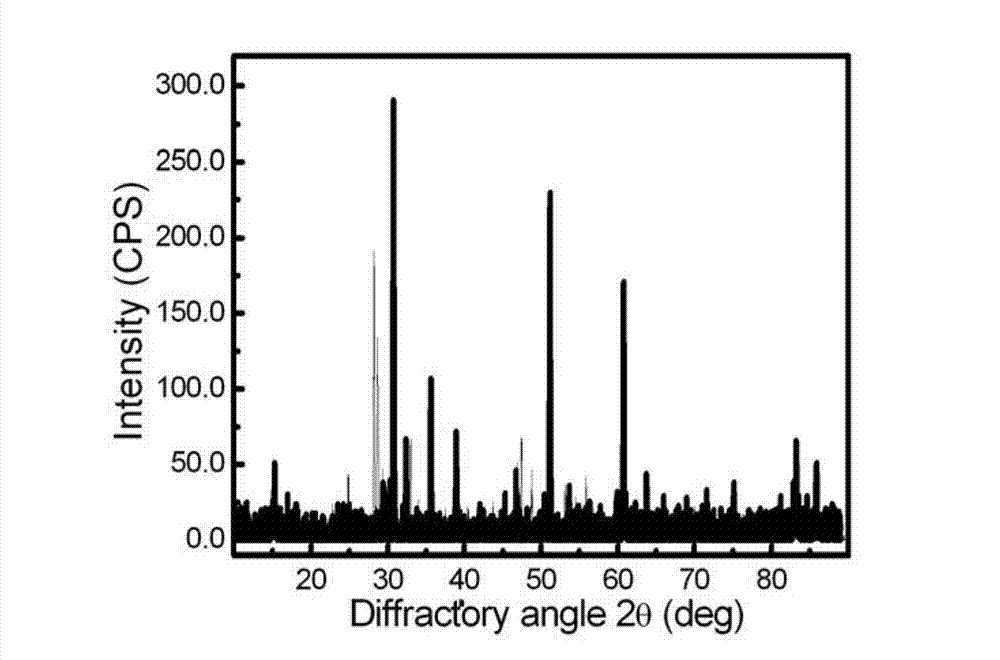

Embodiment 1

[0036] Weigh the raw materials according to the molecular formula of the formula: the molecular formula is K 0.5 Dy 4.5 Ti 4 o 15 , the molecular weight is 1182.3902, the mass of ingredients is 118.2390 g, and the molar number of ingredients is 0.10;

[0037] Weigh the required raw material K 2 CO 3 Mass is 3.490 g; Dy 2 o 3 Mass is 84.216 g, TiO 2 The amount is 36.227 g.

[0038] The preparation method is:

[0039] (1) Put the weighed raw materials into a ball mill jar and mill for 4-48 hours, then put them in a dry box at 80-180 o Tumble dry at C.

[0040] (2) The obtained mixed powder is pre-fired at high temperature to obtain superfine powder. It needs to be heated for 16 hours during pre-burning, and the required temperature is 1100 o C, keep warm for 4 hours.

[0041] (3) After grinding and sieving, add the prepared polyvinyl alcohol glue to the powder, the amount of polyvinyl alcohol added is 10% of the total mass of the raw material design; after pre-pressi...

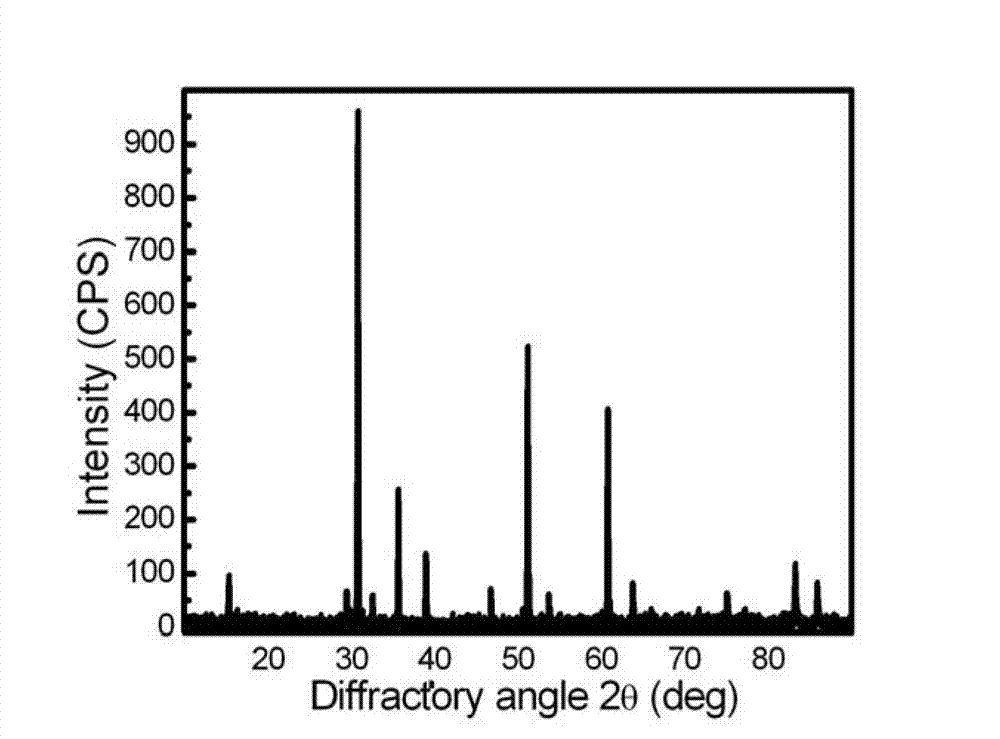

Embodiment 2

[0043] According to the general formula, the raw materials potassium carbonate, titanium dioxide and holmium oxide were weighed.

[0044] Molecular formula is K 0.5 Ho 4.5 Ti 4 o 15 , the molecular weight is 1193.19, the mass of ingredients is 119.319 g, and the molar number of ingredients is 0.10mol;

[0045] The preparation method is:

[0046] (1) Weigh the required raw material K 2 CO 3 Mass is 3.490 g; Ho 2 o 3 Mass is 85.061 g, TiO 2 The amount is 36.227 g.

[0047] (2) Put the weighed raw materials into a ball mill jar for ball milling for 48 hours, and then put them in a drying oven at 180 o Tumble dry at C.

[0048] (3) The obtained mixed powder is pre-fired at high temperature to obtain superfine powder. During pre-burning, the temperature needs to be raised for 20 hours, and the temperature is raised to the required temperature of 900 o After C, keep warm for 5 hours.

[0049] (4) After grinding and sieving, add the prepared polyvinyl alcohol glue to th...

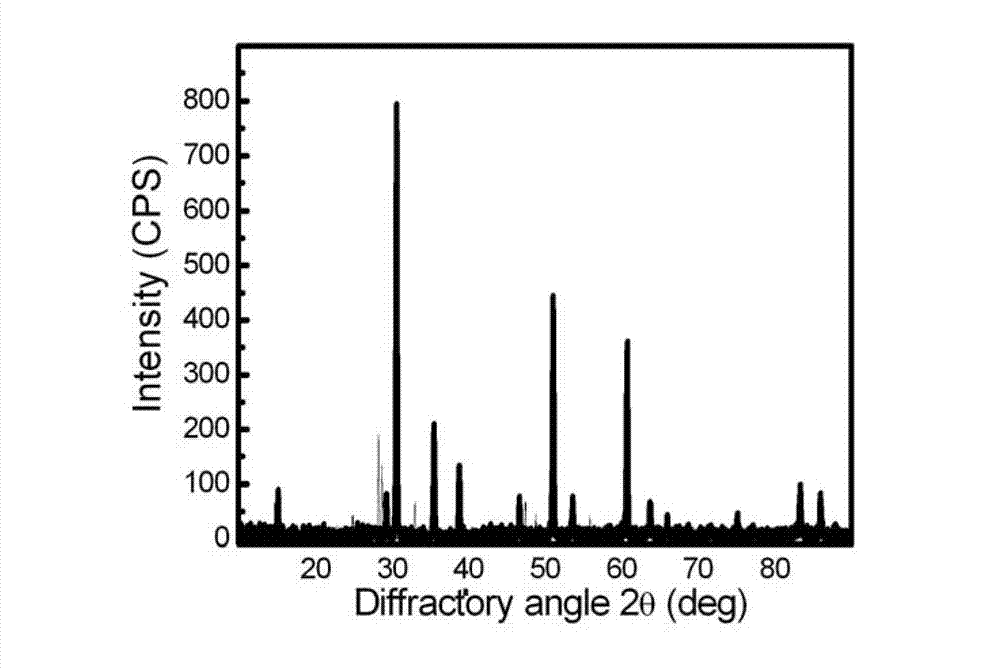

Embodiment 3

[0052] Weigh the raw materials potassium carbonate, titanium dioxide and erbium oxide according to the general formula.

[0053] Molecular formula is K 0.5 Er 4.5 Ti 4 o 15 , the molecular weight is 1203.8102, the mass of ingredients is 120.3810 g, and the molar number of ingredients is 0.10mol;

[0054] The preparation method is:

[0055] (1) Weigh the required raw material K 2 CO 3 Mass is 3.490 g; Er 2 o 3 Mass is 86.076 g, TiO 2 The amount is 36.227 g.

[0056] (2) Put the weighed raw materials into a ball mill jar and mill them for 4 hours.

[0057] (3) The raw materials after ball milling are placed in a drying oven at 180 o C drying, after drying, pulverization, pre-calcination, grinding, and sieving to obtain powder materials; the obtained mixed powder is pre-calcined at high temperature to obtain ultra-fine powder materials. During pre-calcination, the temperature needs to be raised for 12 hours, and the temperature is raised to 1200 °C. o After C, keep wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com