Method for preparing composite electrode material of super capacitor

A supercapacitor and composite electrode technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low rate and unsatisfactory cycle life, and achieve the effects of low equipment use requirements, good cycle stability and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of graphite oxide

[0032] Add 1.5g of graphite and 1.5g of NaNO to a 500ml beaker 3 , 70ml of H 2 SO 4 (98%), sonicated for 15 minutes, then transferred to an ice bath, and then slowly added 9g of KMnO 4 , magnetically stirred for 2 hours, the solution changed from black to brown, then added 100ml of deionized water, magnetically stirred evenly and then added 200ml of water, the solution changed from brown to yellowish brown, then transferred to a water bath at 90°C Stir at constant temperature for 1 hour, the solution turns yellow, when cooled to about 40°C, add 5ml of hydrogen peroxide (30%), then centrifuge several times with deionized water and ethanol, and vacuum freeze-dry the obtained sample for 24 hours to obtain oxidized graphite.

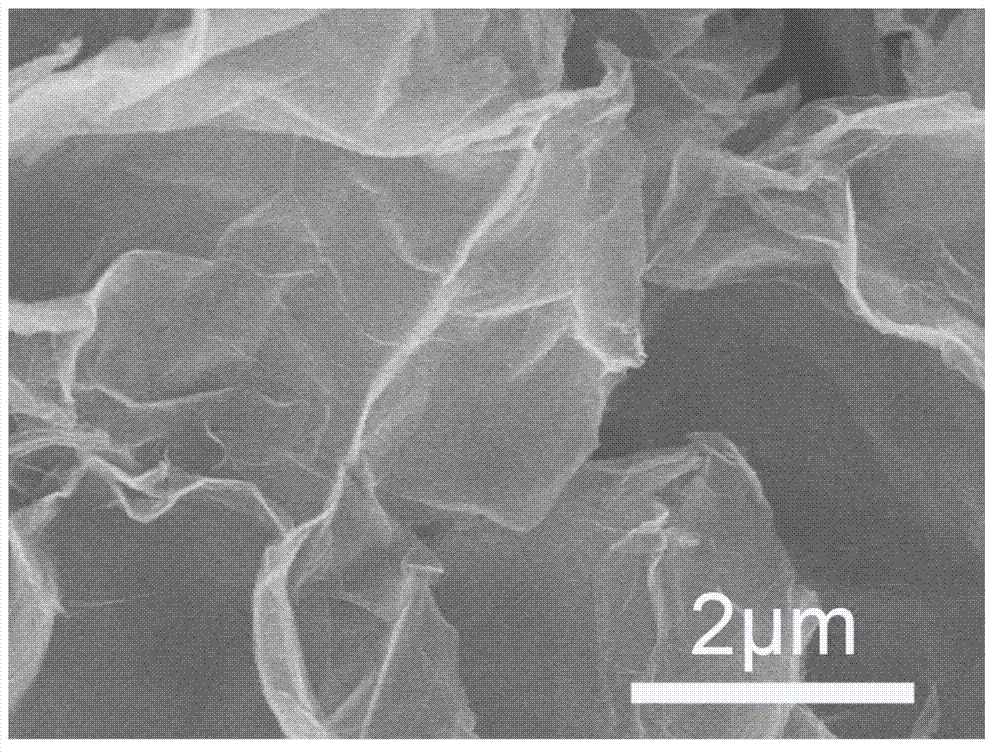

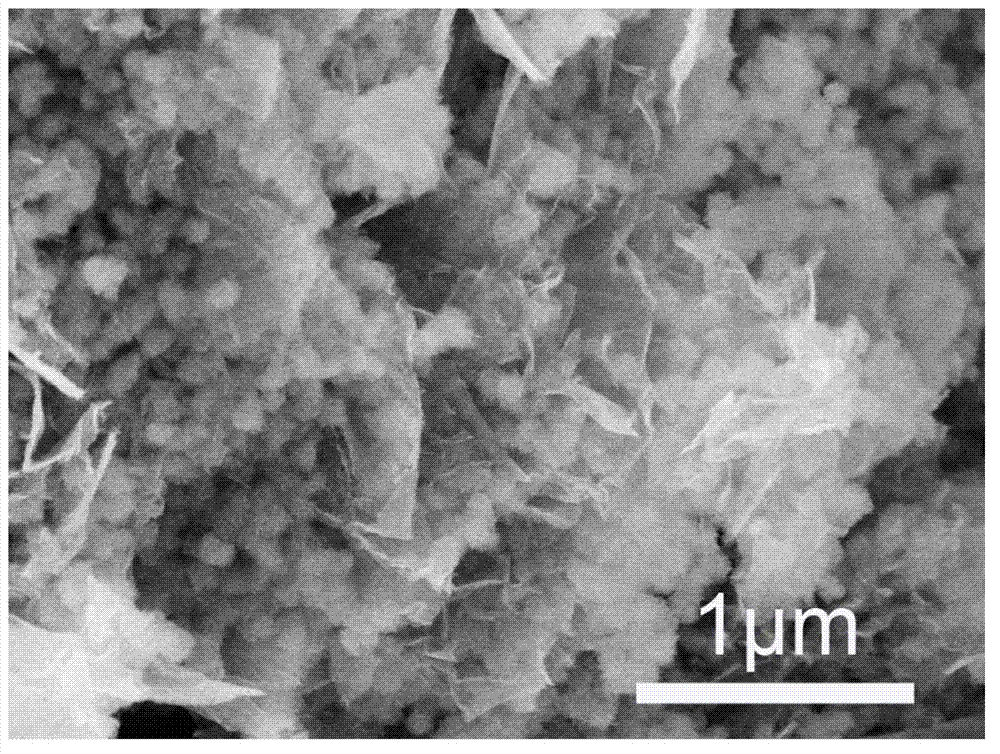

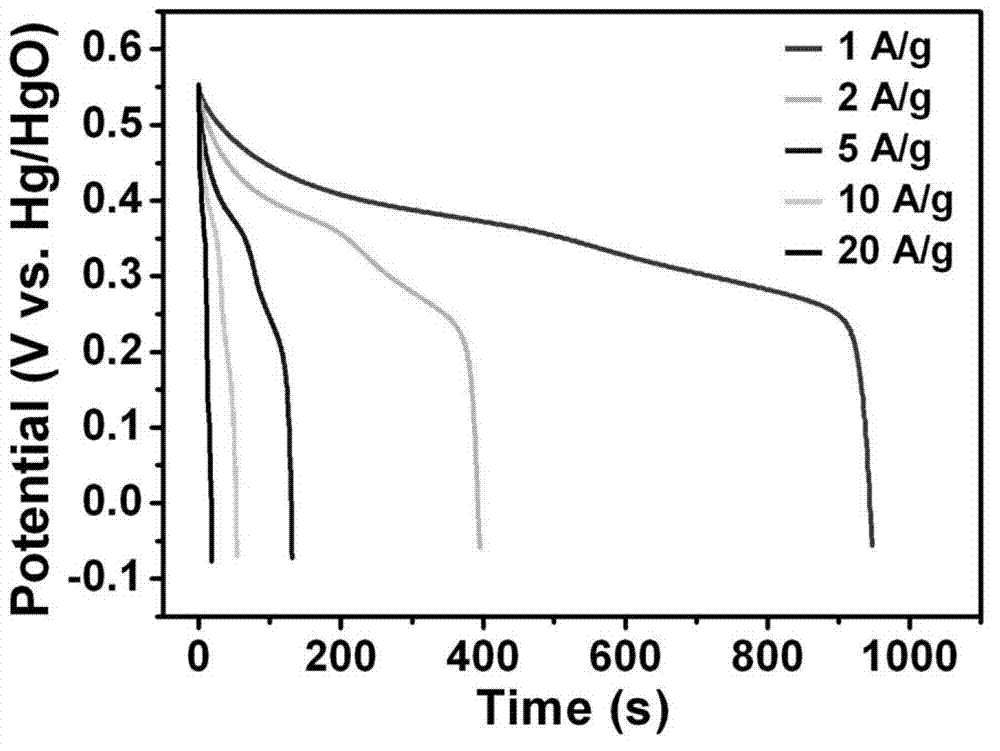

[0033] (2) Preparation of Ni(OH) 2 / CoO / rGO composite electrode material

[0034] Take 12 mg of the prepared graphite oxide and disperse it ultrasonically with 24 ml of ethylene glycol, and at the same time di...

Embodiment 2

[0042] (1) Preparation of graphite oxide

[0043] Add 1.5g of graphite and 1.5g of NaNO to a 500ml beaker 3 , 70ml of H 2 SO 4 (98%), sonicated for 15 minutes, then transferred to an ice bath, and then slowly added 6g of KMnO 4 , magnetically stirred for 1 hour, the solution changed from black to brown, then added 100ml of deionized water, magnetically stirred evenly and then added 200ml of water, the solution changed from brown to yellowish brown, then transferred to a water bath at 80°C Stir at constant temperature for 2 hours, the solution turns yellow, when cooled to about 10°C, add 5ml of hydrogen peroxide (30%), then centrifuge several times with deionized water and ethanol, and vacuum freeze-dry the obtained sample for 24 hours to obtain oxidized graphite.

[0044] (2) Preparation of Ni(OH) 2 / CoO / rGO composite electrode material

[0045] Take 12 mg of the prepared graphite oxide and disperse it ultrasonically with 24 ml of ethylene glycol, and at the same time disp...

Embodiment 3

[0049] (1) Preparation of graphite oxide

[0050] Add 1.5g of graphite and 1.5g of NaNO to a 500ml beaker 3 , 70ml of H 2 SO 4 (98%), sonicated for 15 minutes, then transferred to an ice bath, and then slowly added 18g of KMnO 4 , magnetically stirred for 3 hours, the solution changed from black to brown, then added 100ml of deionized water, magnetically stirred evenly and then added 200ml of water, the solution changed from brown to yellowish brown, then transferred to a water bath at 100°C Stir at constant temperature for 0.5 hours, the solution turns yellow, when cooled to about 20°C, add 5ml of hydrogen peroxide (30%), then centrifuge several times with deionized water and ethanol, and freeze-dry the obtained sample in vacuum for 12 hours to obtain oxidized graphite.

[0051] (2) Preparation of Ni(OH) 2 / CoO / rGO composite electrode material

[0052] Take 12 mg of the prepared graphite oxide and disperse it ultrasonically with 24 ml of ethylene glycol, and at the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com