Black ceramic plate prepared by natural minerals and extracted vanadium tailings and preparation method of black ceramic plate

A technology for extracting vanadium tailings and natural minerals, applied in the field of building decoration materials, can solve problems such as energy consumption, and achieve the effects of eliminating pollution, reducing costs and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

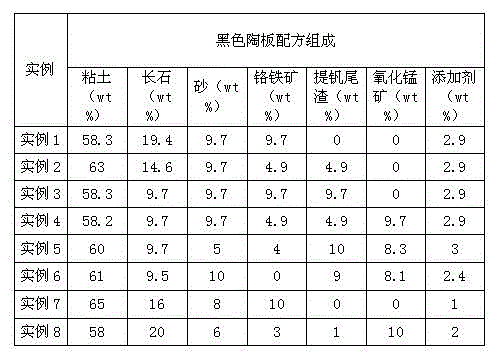

[0021] A method for preparing a black ceramic plate prepared from natural minerals and vanadium extraction tailings, comprising the following steps:

[0022] (1) Drying, dehydrating, crushing and sieving 0-10% vanadium extraction tailings, 0-10% chromite, and 0-10% manganese oxide ore to form a mixed powder;

[0023] (2) Mix the above powder with 58~65% clay, 9~20% feldspar, 5~10% sand, and 1~3% additives to make a moisture content of 14%~19%. The mud balls are formed by dry pressing or wet extrusion;

[0024] (3) Dry the above formed body in a production line drying kiln at a drying temperature of ≦150°C, and then sinter at a temperature of 1000~1200°C to prepare a black ceramic plate.

[0025] As a preference, the vanadium extraction tailings are treated so that the moisture content is ≦2% and the average particle size is D 50 Powder less than 147 μm.

[0026] As a preference, chromite and manganese oxide ore are treated with a moisture content of ≦1% and an average parti...

Embodiment 1

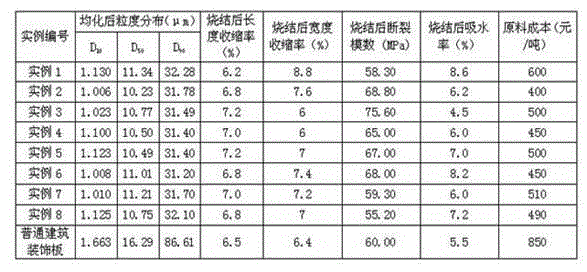

[0029] First, some chromite ore is crushed and sieved, and the chromite ore is processed into a powder with a moisture content of ≦1% and an average particle size of less than 43 μm. Weigh chromite powder, clay, feldspar, and sand according to the ratio of Example 1 in Table 1, and use a mixer and a mud mill to disperse it to make a mud mass with a water content of 14%-19% , and then made into a 300×120×18 mm clay plate with an extrusion molding machine. After molding, put it into the five-layer drying kiln of the production line for drying (drying cycle is 300 min, maximum temperature ≦ 150 ℃), the dry moisture of the product after leaving the drying kiln is <1%, and finally fired at the highest temperature of 1170 ℃ The sintering of the clay panels was done in a roller kiln with a cycle time of 255 min. Based on the same preparation method, the physical properties and costs of the sintered mineral-colored black clay panels and traditional building clay panels are shown in T...

Embodiment approach 2

[0031] First, take some vanadium extraction tailings for drying, dehydration, crushing and screening, and process the vanadium extraction tailings into a powder with a moisture content of ≦2% and an average particle size of less than 147 μm; take some chromite ore for crushing and sieving Sieve treatment, the chromite is processed into a powder with a moisture content of ≦1% and an average particle size of less than 43 μm. Vanadium extraction tailings, chromite powder, clay, feldspar, and sand are weighed according to the ratio of Example 2 in Table 1, and they are dispersed using a mixer and a mud mill to make a moisture content of 14%. -19% clay dough, and then use an extrusion molding machine to make a clay plate of 300×120×18 mm. After molding, it is put into the five-layer drying kiln of the production line for drying (the drying cycle is 300 min, and the maximum temperature is 150 ℃). The sintering of the clay panels was done in a roller kiln with a cycle time of 255 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com