Method for preparing micro-nanostructure on surface of titanium implant

A technology of micro-nano structure and titanium implants, applied in surface reaction electrolytic coatings, electrolytic coatings, coatings, etc., can solve the problems of complex operation, environmental pollution, high cost, simple process equipment, short reaction time, pro- The effect of water performance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Put medical titanium in a sandblasting machine, use 100-mesh ceramic sand, 0.4MPa air pressure, 0.5cm distance, and an inclination angle of 30° for sandblasting;

[0025] 2) After sandblasting, the samples were placed in acetone, ethanol and deionized water for ultrasonic treatment for 15 minutes;

[0026] 3) After cleaning, the sample is suspended in a mixed solution with a mass fraction of 30% sulfuric acid, 1% hydrochloric acid, 1% nitric acid, 0.02 g / L perfluorooctane sulfonate potassium, and deionized water as the rest. Etching treatment for 90min;

[0027] 4) The sample after acid etching was used as an anode, placed in a 0°C solution containing 1g / L sodium dihydrogen phosphate and 3g / L ammonium fluoride, and anodized at 30V for 10 minutes;

[0028] 5) Rinse with plenty of water, dry and cool to constant weight.

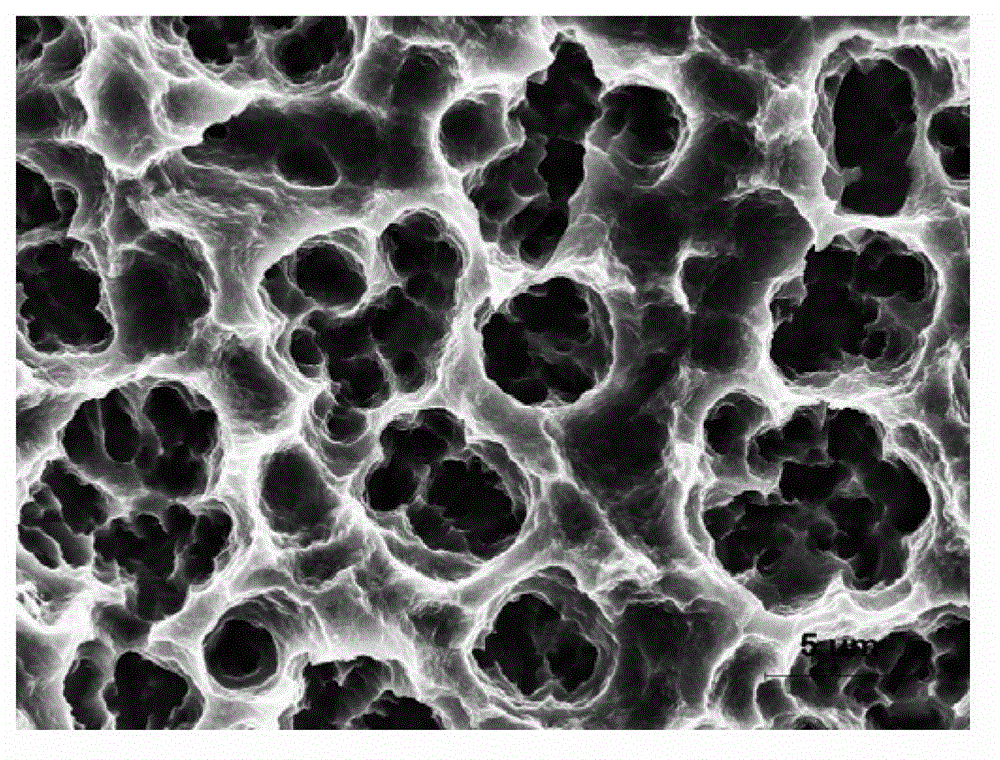

[0029] The scanning electron microscope image of the sample after sandblasting and acid etching prepared in Example 1 is magnified at 3000 times. ...

Embodiment 2

[0036] 1) Put the medical titanium in the sandblasting machine, and use 150 mesh ceramic sand particles, 0.4MPa air pressure, 0.5cm distance and an inclination angle of 45° for sandblasting;

[0037] 2) After sandblasting, the samples were placed in acetone, ethanol and deionized water for ultrasonic treatment for 15 minutes;

[0038] 3) After cleaning, the sample is suspended in a mass fraction of 30% sulfuric acid, 3% hydrochloric acid, and 1% HNO 3 , potassium perfluorooctane sulfonate is 0.06g / L, and the rest is deionized water mixed solution, acid etching treatment at 60°C for 80min;

[0039] 4) The sample after acid etching was used as an anode, placed in a 10°C solution containing 2g / L sodium dihydrogen phosphate and 5g / L ammonium fluoride, and anodized at 30V for 8 minutes;

[0040] 5) Rinse with plenty of water, dry and cool to constant weight.

Embodiment 3

[0042] 1) Put medical titanium in a sandblasting machine, and use 300 mesh ceramic sand, 0.5MPa air pressure, 1cm distance, and an inclination angle of 45° for sandblasting;

[0043] 2) After sandblasting, the samples were placed in acetone, ethanol and deionized water for 10 minutes of ultrasonic treatment in sequence;

[0044] 3) After cleaning, the sample is suspended in a mixed solution with a mass fraction of 40% sulfuric acid, 3% hydrochloric acid, 2% nitric acid, 0.03 g / L perfluorooctane sulfonate potassium, and deionized water as the rest. Etching treatment for 60min;

[0045] 4) The sample after acid etching was used as an anode, placed in a 20°C solution containing 3g / L sodium dihydrogen phosphate and 8g / L ammonium fluoride, and anodized at 20V for 6 minutes;

[0046]5) Rinse with plenty of water, dry and cool to constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com