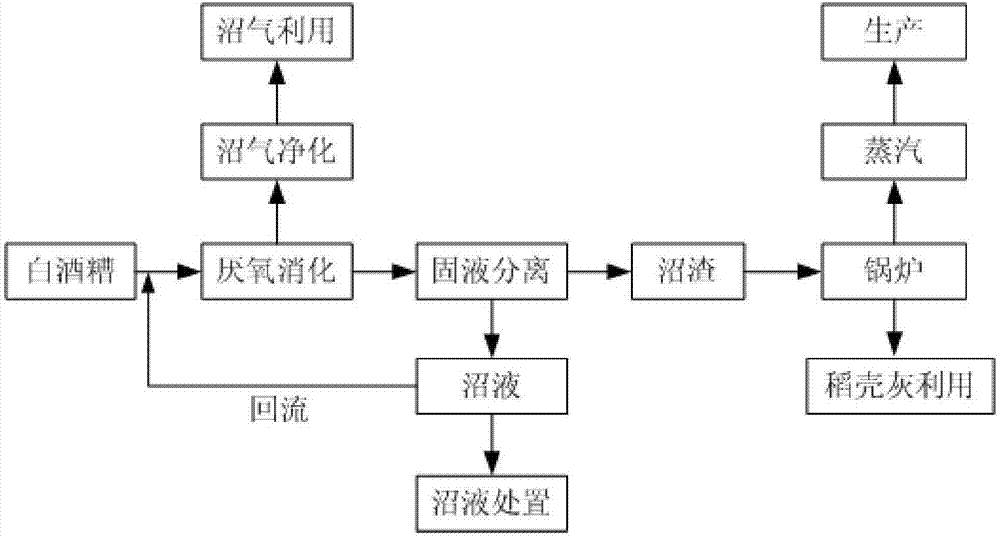

Distillate spirit vinasse spot comprehensive utilization method

A technology of distiller's grains and biogas, which is applied in the field of distiller's grains treatment, can solve problems that affect market promotion and application, cannot be used efficiently in situ, and has a long cycle, so as to promote sustainable development and reduce fossil energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

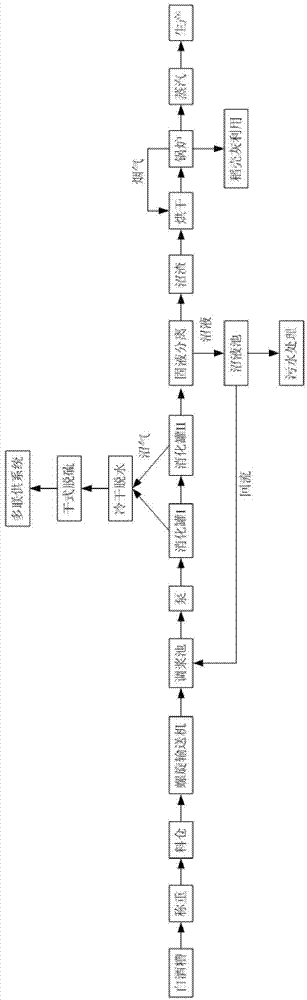

[0054] A liquor factory produces Luzhou-flavor liquor. The daily output of distiller's grains is 200 tons, with a moisture content of 65-70%. Build a comprehensive utilization device for local treatment. The treatment process is attached figure 2 shown.

[0055] 1) The distiller's grains are sent to the biogas station via a belt conveyor, weighed and measured by a belt scale, and then poured into the silo;

[0056] 2) Use the shaftless screw conveyor at the tail of the silo to send it quantitatively and evenly to the slurry tank, where it is mixed and inoculated with the returning biogas slurry, and the temperature is adjusted to 56°C by using the hot water or cold water of the multi-supply system, and then use the screw pump Or the rotor pump is promoted to the anaerobic digestion tank I; the multi-generation system can be supplied as fuel by the biogas produced subsequently;

[0057] 3) In the anaerobic digestion tank I, the solid concentration is maintained at 8-12%, th...

Embodiment 2

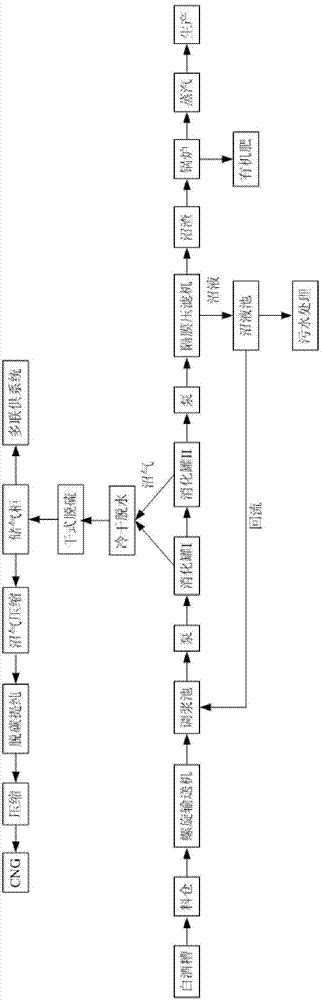

[0064] A liquor factory produces Luzhou-flavor liquor, with a daily output of 400 tons of distiller's grains, with a moisture content of 65-70%. The main components are rice husks and grains (rice, sorghum, wheat, mung beans, glutinous rice, etc.) Build a comprehensive utilization device for local treatment. The treatment process is attached image 3 shown.

[0065] 1) The distiller's grains are sent to the biogas station by a dump truck, weighed and measured by a belt scale, and then poured into the silo;

[0066] 2) Use the shaftless screw conveyor at the tail of the silo to send it quantitatively and evenly to the slurry tank, where it is mixed and inoculated with the returning biogas slurry, and the temperature is adjusted to 40°C by using the hot water or cold water of the multi-generation system, and then the latent sewage is used to The pump or the rotor pump is lifted to the anaerobic digestion tank I; the multi-generation system can be supplied as fuel by the biogas...

Embodiment 3

[0074] A liquor factory produces Luzhou-flavor liquor, with a daily output of 600 tons of distiller's grains and a moisture content of 65-70%. The main components are rice husks and grains (rice, sorghum, wheat, mung beans, glutinous rice, etc.) Build a comprehensive utilization device for local treatment. The treatment process is attached Figure 4 shown.

[0075] Among them, the temperature is adjusted to 60°C in the slurry tank; the solid concentration in the anaerobic digestion tank I is kept at 15-25%, the temperature is controlled at 58±1°C, and high-temperature solid-state fermentation is carried out; the solid state in the anaerobic digestion tank II is The concentration is kept at 6-12%, the temperature is controlled at 55±1°C, and high-temperature solid-state fermentation is carried out.

[0076] The anaerobic digestion system produces about 70,000 cubic meters of biogas per day, which is directly supplied to coal-fired boilers without treatment to support combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com