Method for preparing low-temperature interconnection/high-temperature serving joints by using nano intermetallic compound particles

A nano-metal, high-temperature service technology, applied in the field of micro-connection, can solve the problems of restricting wide application, high cost, affecting electrical and thermal conductivity, etc., and achieve the effect of good compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

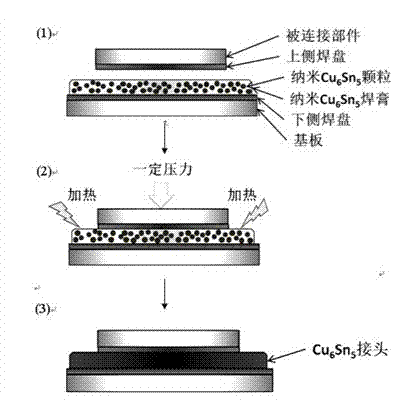

[0016] Such as figure 1 As shown, nano-Cu 6 sn 5 The method for forming a solder paste interconnection joint includes the following steps:

[0017] Step 1: Prepare Cu with a diameter of about 50nm 6 Su 5 particles;

[0018] Step 2: Mix the above nanoparticles with dispersant fish oil, binder α-terpineol, thinner alcohol, and flux in an appropriate amount, and the mixing mass ratio is 80:5:6:4:5;

[0019] Step 3: Use 150W ultrasonic vibration for 60min to make nano-Cu 6 sn 5 The particles are uniformly dispersed in the organic solvent formulated in step 2 to make nano-Cu 6 sn 5 solder paste;

[0020] Step 4: the above nano-Cu 6 sn 5 Put the solder paste on the substrate, complete the alignment of the pads of the parts to be soldered and the pads of the substrate, and apply a pressure of 5MPa;

[0021] Step 5: Put the above system into the reflow furnace, and continue to perform the following actions: heat at a speed of 2~4°C / s to 120~150°C to complete the preheating...

Embodiment 2

[0024] Nano-Cu 3 The method for forming a Sn solder paste interconnection joint includes the following steps:

[0025] Step 1: Prepare Cu with a diameter of about 60nm 3 Sn particles;

[0026] Step 2: Mix the above nanoparticles with dispersant polyvinyl acetate, binder α-terpineol, diluent terpineol, and rosin in an appropriate amount, and the mixing ratio is 82:5:4:4:5;

[0027] Step 3: use 150W ultrasonic vibration for 50min to make nano-Cu 3 Sn particles are uniformly dispersed in the organic solvent formulated in step 2 to make nano-Cu 3 Sn solder paste;

[0028] Step 4: Use the dispensing method to apply the above nano-Cu 3 Place the Sn solder paste on the substrate, complete the alignment of the pads of the parts to be soldered and the pads of the substrate, and apply a pressure of 10MPa;

[0029] Step 5: Put the above system into the reflow furnace, and continue to perform the following actions: heat up to 150°C at a rate of 2~4°C / s to complete the preheating sta...

Embodiment 3

[0031] Nano Ag 3 The method for forming a Sn solder paste interconnection joint includes the following steps:

[0032] Step 1: Prepare Ag with a diameter of about 70nm 3 Sn particles;

[0033] Step 2: Mix the above nanoparticles with dispersant polyethylene glycol ester, binder α-terpineol, diluent ethanol, and rosin in an appropriate amount, and the mixing ratio is 82:5:4:4:5;

[0034] Step 3: use 160W ultrasonic vibration for 45min to make nano Ag 3 Sn particles are uniformly dispersed in the organic solvent formulated in step 2 to make nano Ag 3 Sn solder paste;

[0035] Step 4: The above nano-Ag is printed by screen printing method 3 Place the Sn solder paste on the substrate, complete the alignment of the pads of the parts to be soldered and the pads of the substrate, and apply a pressure of 10MPa;

[0036]Step 5: Put the above system into the reflow furnace, and continue to perform the following actions: heat up to 150°C at a rate of 3°C / s to complete the preheatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com