Preparation of water-soluble CdS:Ag doped nano-crystalline through microwave method

A nanocrystal, water-soluble technology, which is applied in the field of water-phase preparation of doped CdS:Ag semiconductor nanocrystal materials, can solve the problems of complex process, fluorescence attenuation, narrow adjustable range, etc., and achieves low preparation cost and repeatability. Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

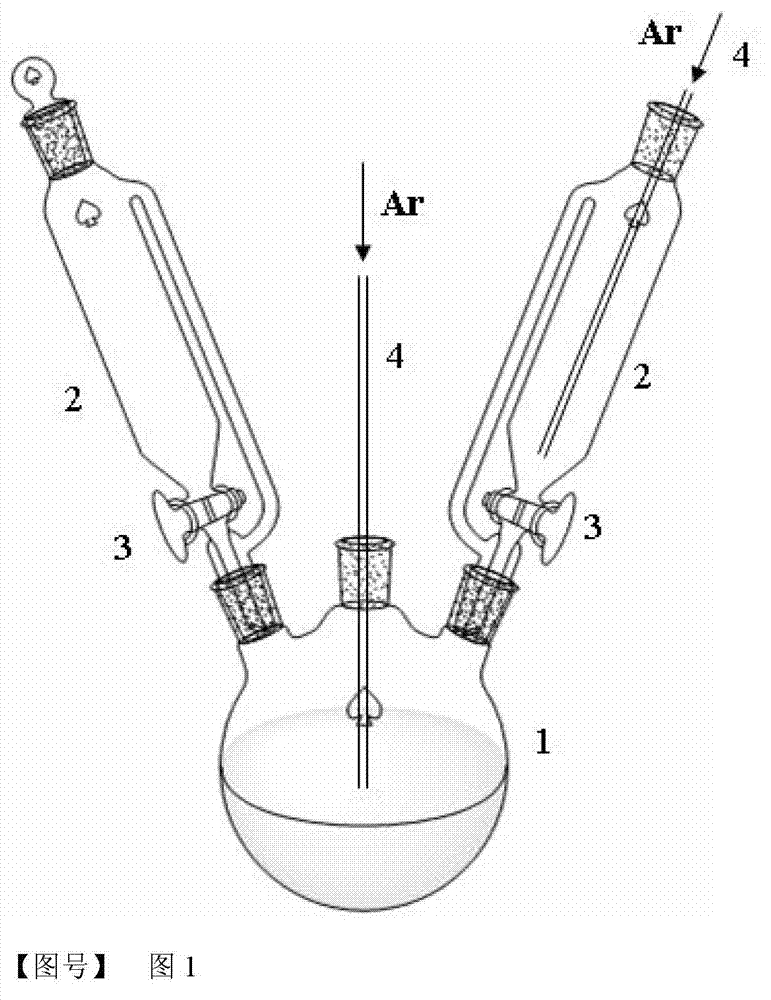

[0017] 1) Preparation of cadmium source

[0018] Take 100 mL of water into a three-necked flask, and then dissolve 29 mg of CdCl 2 2.5H 2 O and 25 μL thioglycolic acid in water, adjust the pH to 9 with NaOH to form a stable cadmium metal complex, the molar ratio of cadmium salt and dispersant is 1:2.5.

[0019] 2) Preparation of doped cadmium source

[0020] Add 5 mL 0.01 molL to 100 mL water -1 Ag + , after completely dissolving, add 1.25 μL of mercaptopropionic acid, mix well, pour into the constant pressure funnel installed on the upper right side of the three-necked flask, and set aside;

[0021] 3) Preparation of sulfur source

[0022] Weigh 156 mg Na 2 S solid, dissolved in 10 mL of water, take 1 mL of Na 2 S solution was poured into the constant pressure funnel on the upper left side of the three-necked flask;

[0023] 4) Open the right side discharge valve on the constant pressure funnel, and slowly put the Ag + The solution is added dropwise to the cadmium so...

Embodiment 2

[0028] 1) Preparation of cadmium source

[0029] Take 100 mL of water into a three-necked flask, and then dissolve 290 mg of CdCl 2 2.5H 2 O and 250 μL thioglycolic acid in water, adjust the pH to 9 with NaOH to form a stable cadmium metal complex, the molar ratio of cadmium salt and dispersant is 1:2.5;

[0030] 2) Preparation of doped cadmium source

[0031] Add 5 mL of 0.1 molL to 100 mL of water -1 Ag + , after completely dissolved, add 12.5μm MPA, mix evenly, pour into the constant pressure funnel installed on the upper right side of the three-necked flask, and set aside;

[0032] 3) Preparation of sulfur source

[0033] Weigh 1.56 g Na 2 S solid, dissolved in 10 mL of water, take 1 mL of Na 2 S solution was poured into the constant pressure funnel on the upper left side of the three-necked flask;

[0034] 4) Open the right side discharge valve on the constant pressure funnel, and slowly put the Ag + The solution is added dropwise to the cadmium source solution, ...

Embodiment 3

[0039] 1) Preparation of cadmium source

[0040] Take 100 mL of water into a three-necked flask, and then dissolve 29 mg of CdCl 2 2.5H 2 O and 25 μL thioglycolic acid in water, adjust the pH to 9 with NaOH to form a stable cadmium metal complex, the molar ratio of cadmium salt and dispersant is 1:2.5, through the airway inserted directly above the constant pressure funnel into the high Pure argon, remove the oxygen contained in the solution;

[0041] 2) Preparation of doped cadmium source

[0042] Add 5 mL 0.01 molL to 100 mL water -1 Ag + , after it is completely dissolved, pour it into the constant pressure funnel installed on the upper right side of the three-necked flask, pass high-purity argon through the air tube inserted directly above the constant pressure funnel, remove the oxygen contained in the solution, and add 12.5 μL of mercaptopropane acid, mix well, set aside;

[0043] 3) Preparation of sulfur source:

[0044] Weigh 156 mg Na 2 S solid, dissolved in 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com