Making method for YAG single crystal for white light LED

A production method and single crystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems affecting the performance of white light LEDs, poor physical and chemical properties, poor uniformity, etc., and achieve good physical and chemical stability and excellent thermal conductivity performance, power-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

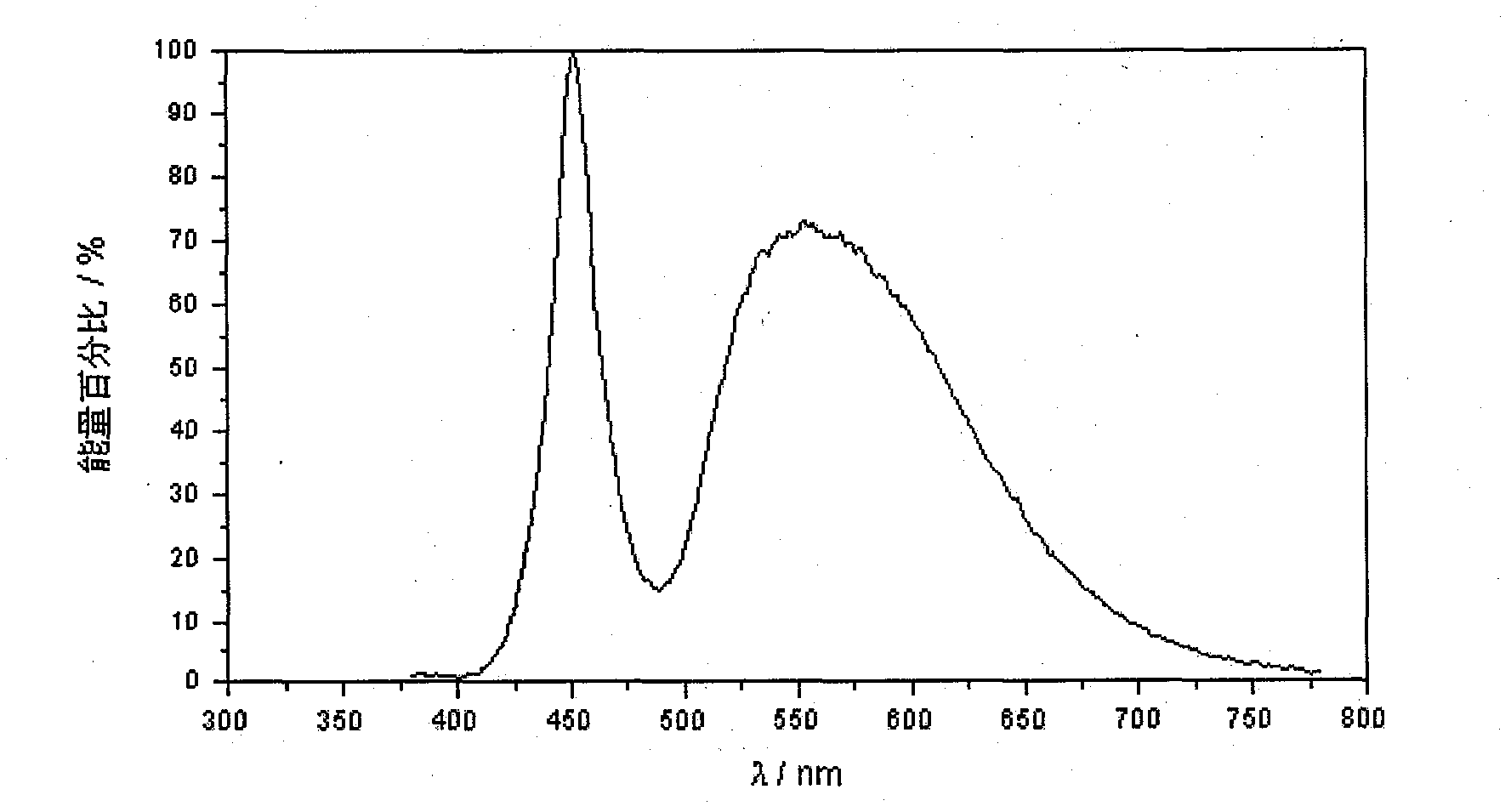

[0017] The composition of YAG single crystal is Y 2.94 Al 5 (O, F) 12 :0.06Ce, the production method is as follows: accurately weigh the raw material Y 2 O 3 66.39g, Al 2 O 3 50.98g, CeF 3 2.37g, BaF 2 3.51g, the above-mentioned raw materials are pre-processed, the sintered raw materials are put into a 60mm diameter iridium crucible, heated to 1970°C in a D400 single crystal furnace to melt, and pure YAG single crystal rods are used as seed crystals for crystal growth. The rotating speed is 12r / min, the equal-diameter drawing speed is 2.0mm / h, and crystals of a certain size are grown. Fix the grown crystal on the glass according to the required size and cut it with a carbon chip cutting machine. The wafer is soaked in acetone for grinding and polishing. The microscopic observation is free of blisters and defects, and then polishing for more than 6 hours. The chip size is a single chip with a thickness of 0.2mm and a side length of 29mm. The single chip is packaged with a shad...

Embodiment 2

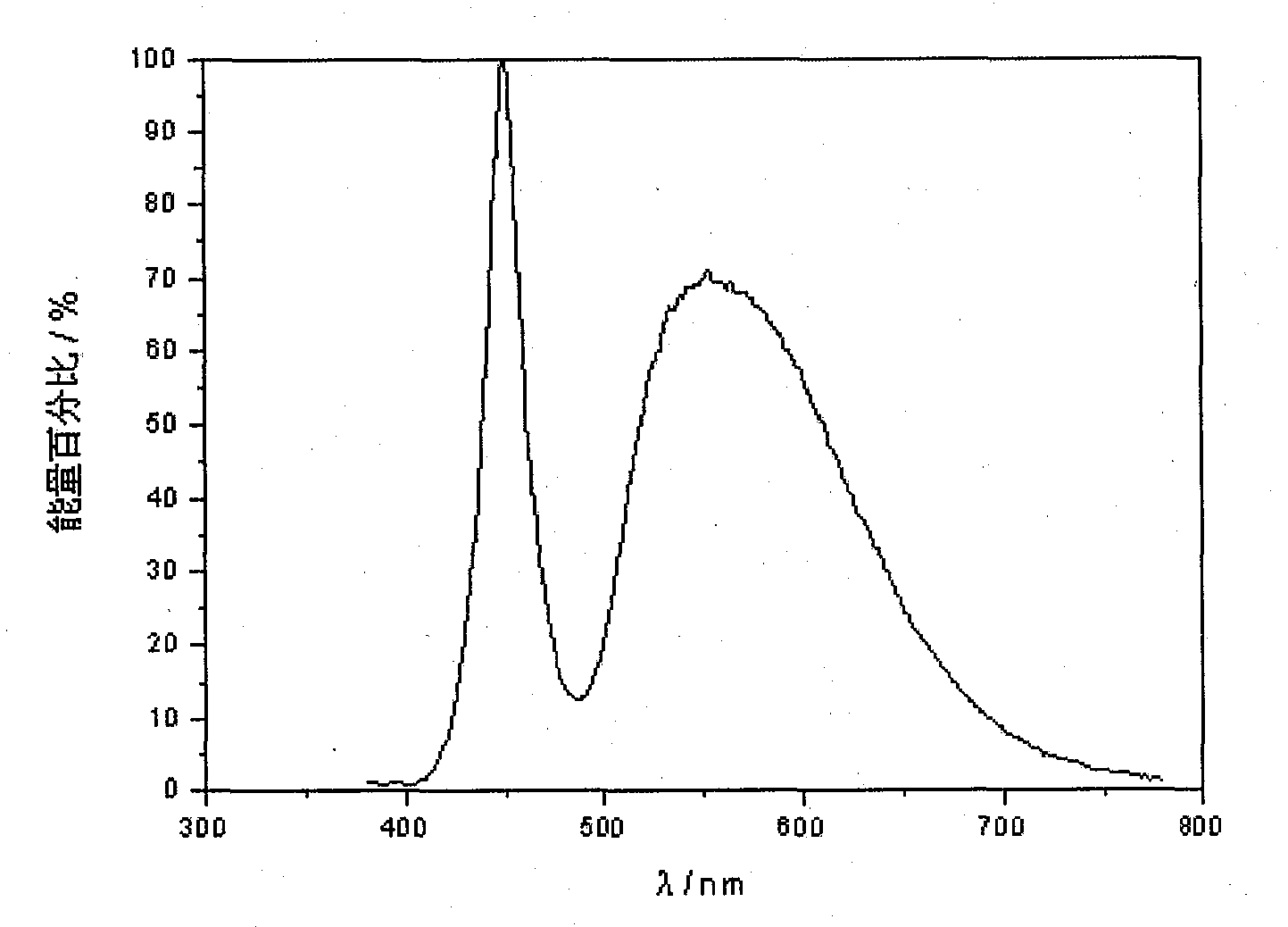

[0019] The composition of YAG single crystal is Y 2.92 Al 4.8 Mg 0.1 Ti 0.1 (O, F) 12 :0.08Ce, the production method is as follows: accurately weigh the raw material Y 2 O 3 65.94g, Al 2 O 3 48.94g, CeF 3 3.15g, MgO 0.81g, TiO 2 1.60g, BaF 2 3.51g, pre-process the above raw materials, put the sintered raw materials into a 60mm diameter iridium crucible, heat it to 1970℃ in the D400 single crystal furnace to melt, and use the pure YAG single crystal rod as the seed crystal to grow the crystal. It is 12r / min, the equal-diameter pulling speed is 2.0mm / h, and crystals of a certain size are grown. Grind and polish the wafer, observe microscopically without blisters and defects, and polish for more than 6 hours. Polish the single crystal into a single wafer with a thickness of 0.5mm and a side length of 53mm. Use a shadowless adhesive for the single wafer Packaged on 50 3W integrated LED chips with a rated power of 150W (the light-emitting area of the integrated 50 chips is 50m...

Embodiment 3

[0021] The composition of YAG single crystal is Y 2.82 Gd 0.1 Al 4.8 Mg 0.1 Ti 0.1 (O, F) 12 :0.08Ce, the production method is as follows: accurately weigh the raw material Y 2 O 3 63.68g, Gd 2 O 3 3.63g, Al 2 O 3 48.94g, CeF 3 3.15g, MgO 0.81g, TiO 2 1.60g, BaF 2 3.51g, pre-process the above raw materials, put the sintered raw materials into a 60mm diameter iridium crucible, heat it to 1970℃ in the D400 single crystal furnace to melt, and use the pure YAG single crystal rod as the seed crystal to grow the crystal. It is 11r / min, the equal-diameter pulling speed is 2.2mm / h, and crystals of a certain size are grown. The single crystal is polished and processed into a single chip with a thickness of 0.8mm and a side length of 55mm. The single chip is packaged with a shadowless adhesive on 50 3W integrated LED chips, with a rated power of 150W (the light-emitting area of the integrated 50 chips is 50mm*50mm) is packaged on the device to complete the LED, the adjustment curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com