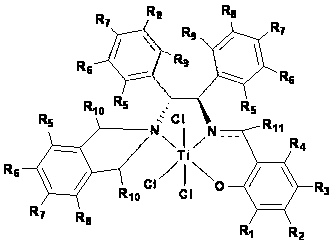

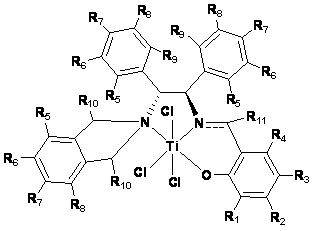

Tridentate Schiff base titanium-based olefin polymerization catalyst and preparation method and application thereof

A Schiff base titanium-based olefin and polymerization catalyst technology, applied in the direction of titanium organic compounds, etc., can solve the problems of uncontrollable polymer structure and performance, and achieve the effects of high yield, simple synthesis route and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of 1,3-dimethyl-5-acetyl-barbituric acid (DAB)

[0026] The structural formula of 1,3-dimethyl-5-acetyl-barbituric acid (DAB) is:

[0027]

[0028] Put 6.40 grams of 1,3-dimethylbarbituric acid and 150 ml of acetic anhydride into a dry round-bottomed flask, add 5 drops of concentrated sulfuric acid dropwise under the condition of vigorous stirring, distill the acetic anhydride after reflux for 2 hours, cool The precipitated solid was washed successively with hot water and acetone, and vacuum-dried to obtain 5.90 g of yellow powder with a yield of 65%. (T. Arai et al., Org. Lett., 2007, 9, 3595)

Embodiment 2

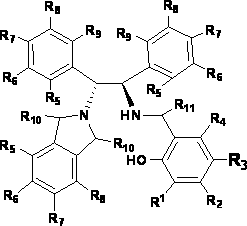

[0029] Example 2 Preparation of unilaterally protected diphenylethylenediamine

[0030] The structural formula of unilaterally protected diphenylethylenediamine is:

[0031]

[0032] Under nitrogen protection, 2 g of diphenylethylenediamine, 1.87 g of DAB, and 20 ml of anhydrous tetrahydrofuran were added, and stirred at room temperature for 48 hours. After removal of the solvent, column chromatography yielded 3.14 g of a white solid with a yield of 94%. (T. Arai et al., Org. Lett., 2007, 9, 3595)

Embodiment 3

[0033] Example 3 Preparation of 1,2-diphenyl-1-isoindolyl-2-amine-DAB

[0034] The structural formula of 1,2-diphenyl-1-isoindolyl-2-amine-DAB is:

[0035]

[0036] Add 2.27 grams of unilaterally protected diphenylethylenediamine, 1.76 grams of o-dibenzyl bromide, 2ml of diisopropylethylenediamine, and 20ml of N,N-dimethylformamide under nitrogen protection, and stir at 40°C for 48 After one hour, water was added to stop the reaction, and the product was extracted with ethyl acetate. After removal of the solvent, column chromatography gave 2.39 g of a yellow solid, with a yield of 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com